Welcome to the new age where data is king, specifically in the intricate area of supply chain analytics (SCA). The traditional method of relying solely on spreadsheets and basic statistical analysis for SCA has evolved: It’s no longer just about simple need forecasts and predictions based on isolated data points from different segments of the supply chain. We’ve stepped into a time where big data analysis reigns, capable of turning a complex puzzle of data into a unified, potent asset for your enterprise.

We’re seeing a major change in how companies handle their logistics. So what is supply chain analytics? Well, with newer, better ways to analyze data, we can now gather and make sense of data from all over the supply chain. This doesn’t just make things smoother; it also brings to light valuable insights that were once lost in a sea of data. This shift is a game-changer, enabling companies to make smarter choices, fine-tune their operations, and get more bang for their buck from their efforts.

Data analytics has occurred as a groundbreaking force in this rapidly evolving market. It became the difference between leading the pack and trailing behind. IntelliSoft is here to guide you through this shift, showing you how to harness the advantages of supply chain analytics software solutions to survive and thrive. We’ve been riding the wave of this transformation, pioneering the integration of advanced data analysis in the logistics sector.

In today’s business world, efficient data management is crucial for informed decision-making, streamlined operations, and gaining a competitive edge. Let’s explore how you can turn numbers into narratives that drive your business forward.

Table of Contents

How Does Supply Chain Analytics Work?

In the domain of supply chain management, analytics is an innovative and efficient tool. SCA is the art and science of applying quantitative methods to extract actionable foresights from information, embracing everything from the movement of goods to financial streams across the entire supply chain. Its ultimate goal? To boost efficiency, slash costs, and supercharge overall performance.

The Process Breakdown

Picture the supply chain as a vast network of information streams. The first step in harnessing this network is data collection. From the core of internal systems like ERP (Enterprise Resource Planning), WMS (Warehouse Management Systems), and TMS (Transportation Management Systems) to the external realms of suppliers, customers, and third-party logistics providers, data is gathered, forming the bedrock of our analytics journey.

However, raw data is often messy with formats, errors, and inconsistencies. Enter the crucial phase of data cleansing and preparation. Here, data is refined, errors are corrected, duplicates are removed, and formats are standardized. It’s like filtering gold from the sand, ensuring the data is pristine and primed for analysis.

Imagine possessing a chest full of pristine information – that’s where the magic kicks off in SCA. The core of it all? Analysis. It’s all about turning this data into golden insights. How does it happen? Using a range of analytical procedures. We start with descriptive analytics that tell the story of what went down. Then there’s diagnostic analytics, which is like a detective deciphering why things happened.

Predictive analytics in supply chain is your crystal ball, giving a glimpse into what’s coming up next. And finally, prescriptive analytics acts as your guide, advising on the best steps to take. What are the tools for this journey? We’ve got statistical analysis, machine learning models, and algorithms fine-tuned for optimization.

The insights gleaned are then dressed for the show – visualization and reporting. Complex data findings are translated into user-friendly consoles and reports at this stage. By visualizing data, we turn hard-to-grasp numbers into coherent, actionable insights, allowing those in charge to make informed decisions swiftly and with confidence.

The real challenge in SCA is putting these insights into action. Implementation might involve strategic shifts such as refining inventory levels, tweaking supplier management, enhancing demand prediction, or overhauling logistics strategies. It’s about turning insights into practical steps, ensuring the supply chain operates like a well-oiled machine.

The supply chain landscape is ever-changing. Thus, the final piece of the puzzle is continuous monitoring and improvement. After implementing changes, monitoring the outcomes and tweaking the processes based on new data and feedback is crucial. This ongoing cycle ensures that the supply chain stays agile, adaptable, and ahead of the curve.

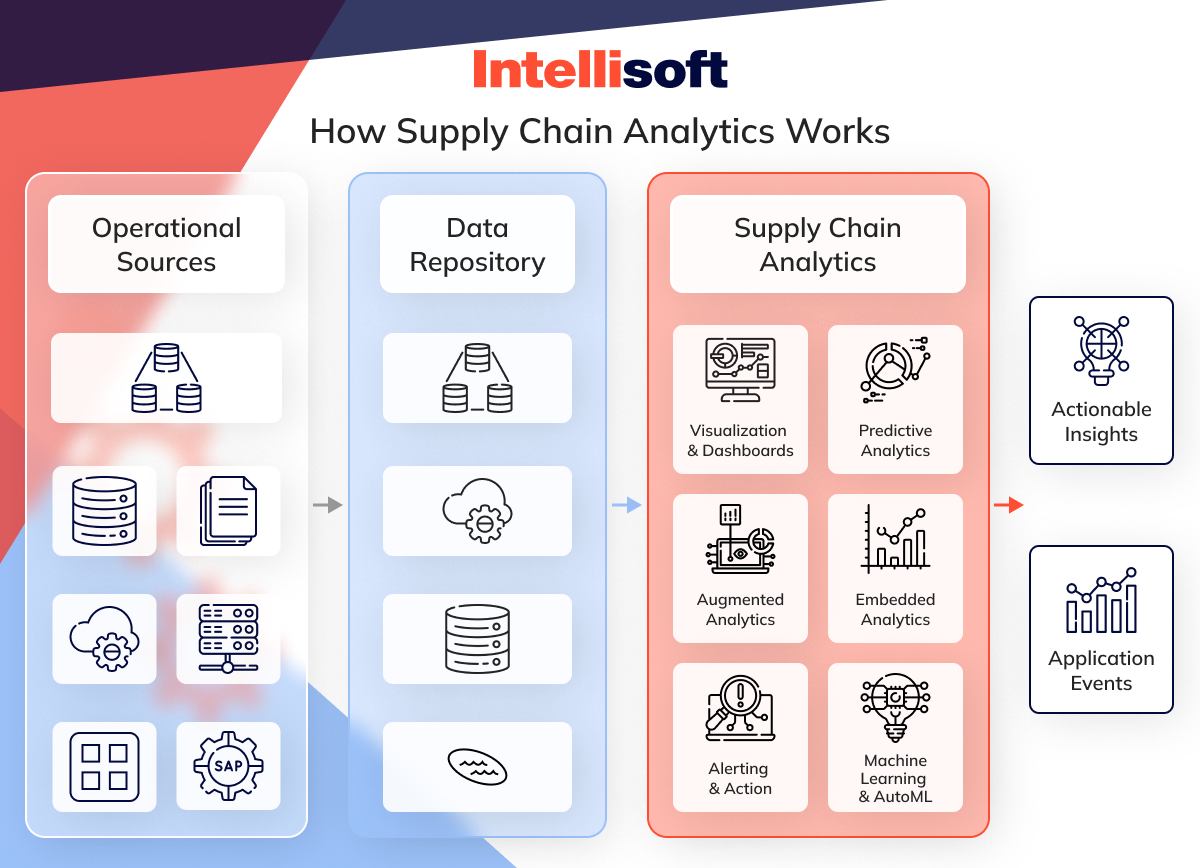

Supply Chain Data Analytics Workflow

The supply chain data analytics workflow is a sophisticated dance of data integration and application. It starts with sourcing data from operational systems:

- Procurement

- Inventory management

- Orders

- Warehousing

- Fulfillment

- Transportation

This data is enriched with inputs from third-party suppliers, carriers, and merchants.

This diverse data is then extracted, transformed, and funneled into a centralized repository – a data warehouse or data lake, typically housed in the cloud. This centralization offers a bird’s-eye view of the logistics network, laying the groundwork for in-depth analysis.

Getting your hands on a top-tier supply chain data analytics tool is like unlocking a new level of analysis. Take predictive supply chain data analytics, for instance. It’s not just about crunching numbers – it’s a game-changer for forecasting and smart inventory management. These supply chain analytics tools do a lot more than just sift through data. They’re like your personal data wizards, creating interactive charts and dashboards that do more than just look pretty. They let you spot trends and get to the heart of crucial metrics – like how smoothly your orders are being filled, where your inventory is, and how fast things are moving in your supply chain.

The best supply chain analytics tools offer augmented analytics capabilities, including automated machine learning (AutoML), supply chain predictive analytics, and prescriptive analytics. They allow seamless integration with other applications, enabling data-driven decision-making permeating every facet of the supply chain.

The culmination of this workflow is actionable insights that can be implemented directly or used to trigger alerts and actions in other systems. SCA is weaving data into the very fabric of supply chain operations, driving efficiency, responsiveness, and strategic agility in an ever-evolving business landscape.

Related readings:

- Warehouse Automation Systems: Revolutionizing Supply Chains for Unprecedented Efficiency

- How Predictive Analytics Solutions Are Benefitting Supply Chain

- Machine Learning in Logistics Industry: Benefits and Use Cases

- How to Develop Logistics Management System: Timeframe, Tech Stack, and Costs

- Inventory Management Database Strategies: Optimizing Your Inventory Control

Why is Supply Chain Analytics Important?

In the intricate and fast-paced world of supply chains, the importance of analytics cannot be overstated. SCA is a cornerstone for businesses seeking efficiency, profitability, and a competitive edge. Let’s discuss the key reasons that underscore the significance of SCA.

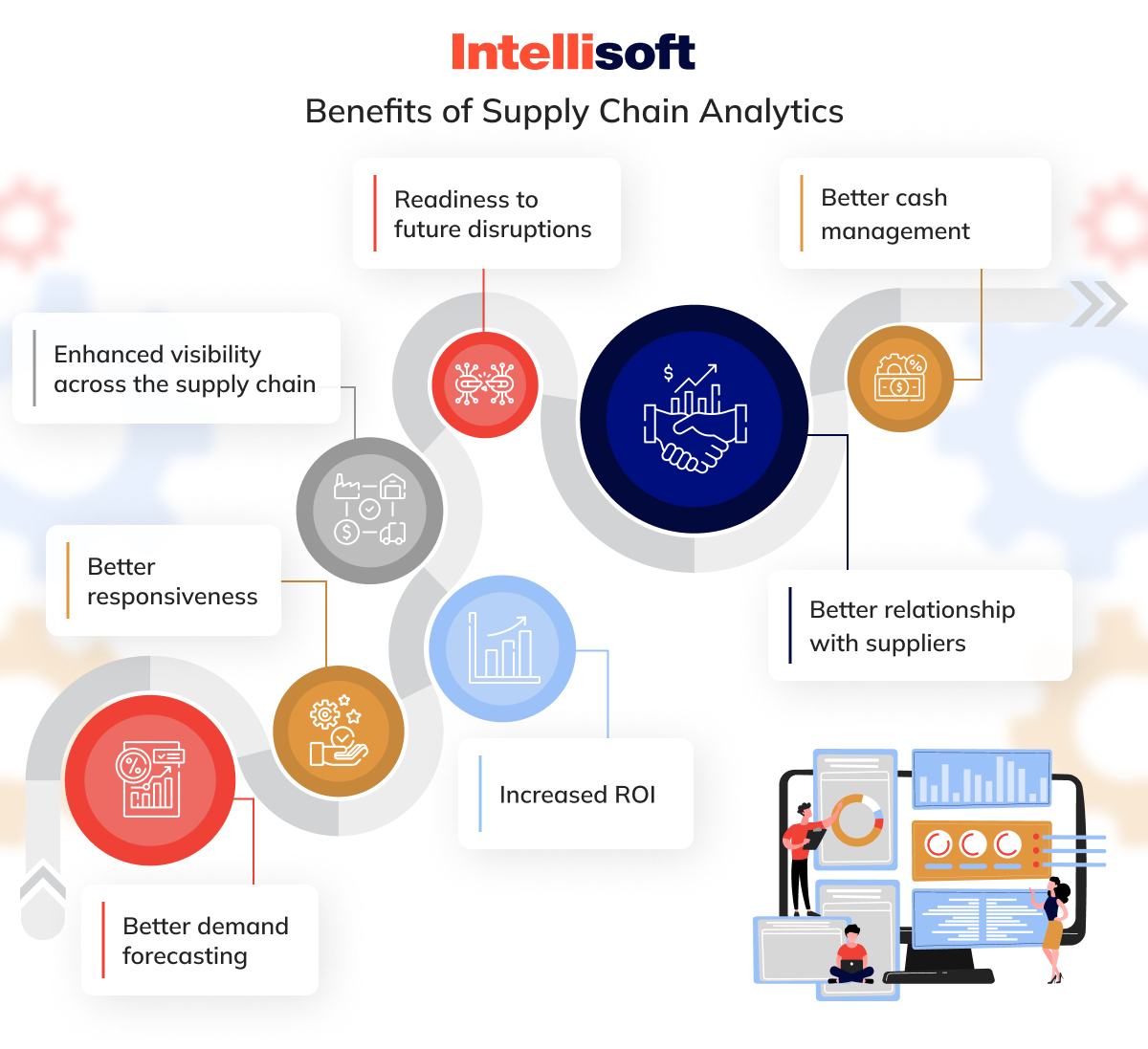

The Pillars of Enhanced Data Analytics in Supply Chain Management

At its core, SCA serves as the guiding light for decision-making. Providing actionable insights empowers managers to make strategic choices, be it optimizing inventory levels, selecting top-tier suppliers, or streamlining logistics operations. The result? Decisions that are not just timely but also backed by solid data.

Analytics is like the magnifying glass highlighting the inefficiencies and bottlenecks within supply chain processes. By identifying these areas, companies can pave the way for automation, process improvement, and a leaner operation. This transition trims down costs and ramps up productivity, making the entire supply chain more effective.

In today’s customer-centric market, meeting demand accurately is paramount. Analytics aids in predicting customer needs with precision, ensuring the availability of the right products at the right time. This responsiveness is a key factor in boosting customer satisfaction and fostering loyalty.

The supply chain is a terrain filled with potential hazards – from supplier issues to transportation snags. SCA acts as a radar, detecting these risks early on. This foresight allows companies to devise contingency plans, effectively mitigating risks before they can ripple through the business.

A meticulous analysis of spending patterns and procurement practices can unearth significant opportunities for cost reduction. Analytics enables companies to trim the fat without sacrificing quality or delivery efficiency, leading to a more cost-effective operation.

Data analysis provides valuable insights in an innovation-driven environment. These insights can fuel innovative supply chain strategies, propelling companies ahead of their competitors and securing a more dominant position in the market.

The road towards a more environmentally friendly supply chain is frequently constructed by utilizing data. Analytics can pinpoint ways to reduce carbon footprints, such as optimizing transportation routes or choosing eco-friendly suppliers, steering companies towards more sustainable practices.

By scrutinizing supplier performance data, your company can fortify alliances with the best suppliers. This analysis can lead to more favorable terms and a more reliable supply chain.

In an ever-changing market, agility is key. A data-driven approach equips your company to swiftly adapt to market fluctuations, scale operations as needed, and respond promptly to emerging opportunities or challenges.

Supply chain analytics offers heightened visibility and transparency across the entire chain. This clarity is crucial for managing complex, global supply chains and ensuring adherence to various regulatory standards.

Supply chain software analytics has become a crucial strategic asset for businesses. It allows them to have an end-to-end view of their supply chain, which enables informed decision-making, enhances operational efficiency, and keeps them ahead of the competition in the global market.

Tracing the Roots: A Brief History of SCA

The term ‘supply chain analytics’ sounds modern, doesn’t it? But hold on to your seats (and your spreadsheets), because we’re about to take a trip back in time. Yes, a history lesson – but I promise it’s not the snooze-fest you endured in high school.

The Early Days: Papyrus and Predictions

Long before the SCA was even a twinkle in a logistician’s eye, ancient civilizations were already on it. Think about the Egyptians building the pyramids – they had to figure out how to get those massive stones from quarries to construction sites. No easy feat without a good plan (and, unfortunately for them, no heavy machinery).

Fast forward a few centuries to the Industrial Revolution. This is where things start getting juicy. The rise of factories and railways brought about the need for more sophisticated planning. Goods had to move faster and in larger quantities than ever before. Cue the early stages of what we would now recognize as supply chain management.

The Post-War Boom: Computers Enter the Scene

The real game-changer came after World War II. This is the period when computers started strutting their stuff. Initially, these machines were gigantic, expensive, and, let’s face it, not exactly user-friendly. But they were a start. Businesses began to use them for basic inventory management – a far cry from the Excel spreadsheets we’re all glued to today.

In the 1960s and 1970s, things started heating up. We saw the introduction of Material Requirements Planning (MRP) systems. These were the ancestors of the modern Enterprise Resource Planning (ERP) systems. They were a big deal because, for the first time, companies could manage production schedules and inventory more efficiently. It was like seeing color TV for the first time – mind-blowing!

The Digital Revolution

Enter the digital age. Computers shrunk down from room-sized behemoths to something that could fit on a desk (and eventually, in our pockets). Software became more sophisticated, and the internet changed the game entirely.

This was the moment when SCA really started to flex its muscles. We’re talking about advanced prediction methods, real-time information review, and even early forms of AI. It was like watching a child prodigy grow up – exciting, unpredictable, and full of potential.

The 21st Century: Big Data and Even Bigger Ideas

Now, let’s zoom into the 21st century when big data entered the scene. With the explosion of e-commerce and global trade, the amount of data available for analysis grew exponentially. It was like drinking from a fire hose – overwhelming but exhilarating.

Companies began to use this data to not just track, but predict and improve their logistics. Predictive analysis allowed companies to foresee potential disruptions and find ways to mitigate risks. SCA was no longer just about improving logistics operations – it became about gaining a competitive edge.

Today, supply chain analytics is a dynamic field, blending cutting-edge technology with business acumen. With the advent of IoT, AI, and machine learning, the possibilities seem endless. From the pyramids to predictive algorithms, it’s been quite the journey. And the best part? It’s still evolving.

What Are the Types of Supply Chain Analytics?

Supply Chain Analytics (SCA) isn’t just another cog in the business machine – it’s a powerhouse, offering way more than your average data crunching. It’s like a Swiss Army knife, equipped with various methods and tools, each designed to fine-tune every piece of the supply chain puzzle. From the moment materials are picked up to the time the final product lands in the customer’s hands, SCA is there, making sure everything runs like clockwork. Let’s dive into the different flavors of supply chain analytics. Each one zeroes in on specific parts of the supply chain, all with the goal of smoothing out the wrinkles and boosting efficiency.

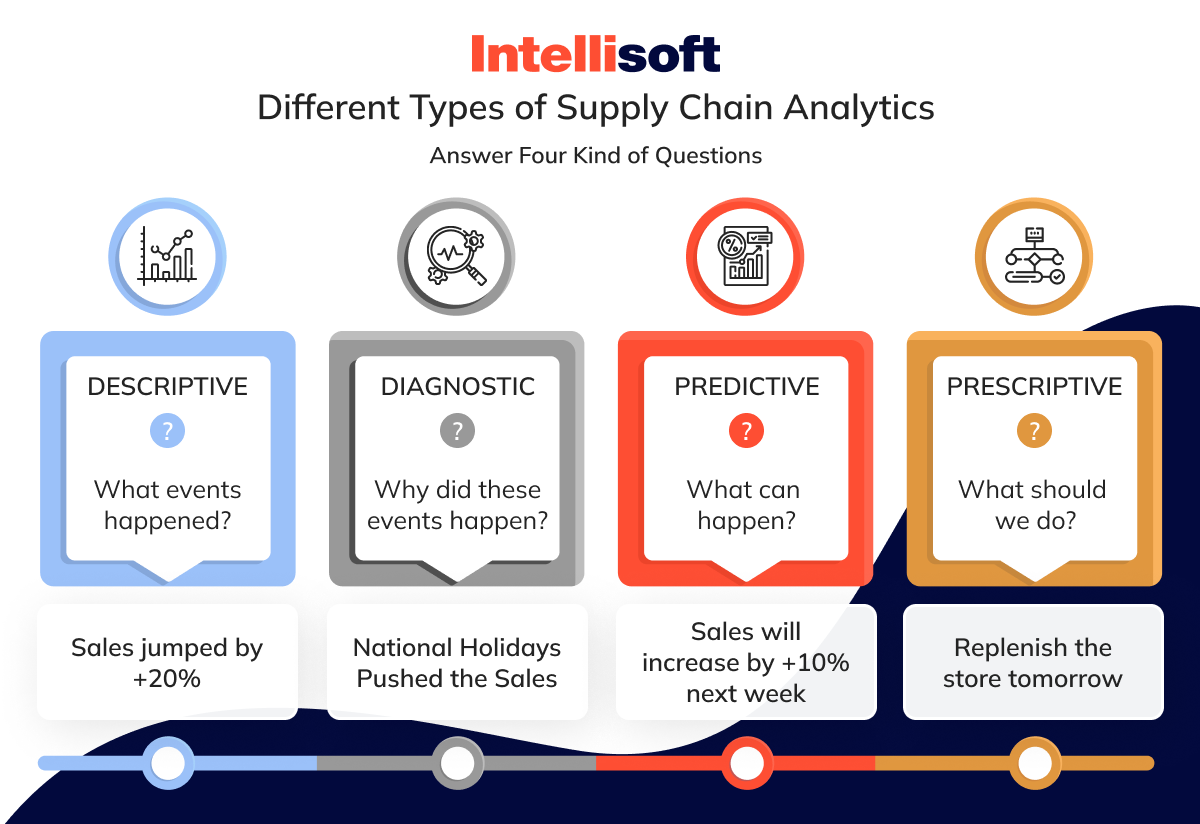

Descriptive Analytics

Think of descriptive analytics as the historian of your supply chain. It’s all about diving deep into historical data. This process involves gathering and scrutinizing past information to spot trends, patterns, and insights. It’s like looking at a history book to understand what happened in your supply chain. By getting a grip on past events and decisions, your organization can get a clear view of where it stands now. This process is the foundation for understanding the supply chain’s intricate workings.

Diagnostic Analytics

Now, Diagnostic Analytics acts like a detective. It’s not satisfied with just knowing what occurred – it needs to know why. This process involves deep analysis, like data mining and examining correlations. Think of it as investigating the crime scene of past performances to figure out the root causes. This type of analytics is crucial for companies eager to understand the forces driving their supply chain stats.

Predictive Analytics

Supply chain predictive analytics management can be compared to your supply chain’s crystal ball. It uses advanced algorithms and prediction tricks to guess what might happen next. By learning from the past and using machine learning and AI, it predicts future trends and potential hiccups. This form of predictive analytics supply chain management is a key player for businesses that want to stay ahead of the game and plan strategically.

Prescriptive Analytics

As the name hints, this is about giving specific advice to hit your goals or tackle challenges. It uses complex algorithms and simulations to show you different decision paths and their potential outcomes. This is crucial for fine-tuning supply chain decisions and operations, steering companies towards better efficiency and effectiveness.

Cognitive Analytics

This is where AI and machine learning step in to mimic human thought processes in the supply chain. It can understand natural language and sift through messy data, offering sharp insights and solid advice. It’s the go-to for solving complicated problems and making decisions in supply chains, handling stuff that’s too intricate for traditional analytics.

All these analytics flavors play unique, interconnected roles in making your supply chain more visible, efficient, and effective. By mixing and matching these methods, your organization can get a 360-degree view of how your supply chain ticks, spot upcoming trends, and make decisions that really move the needle.

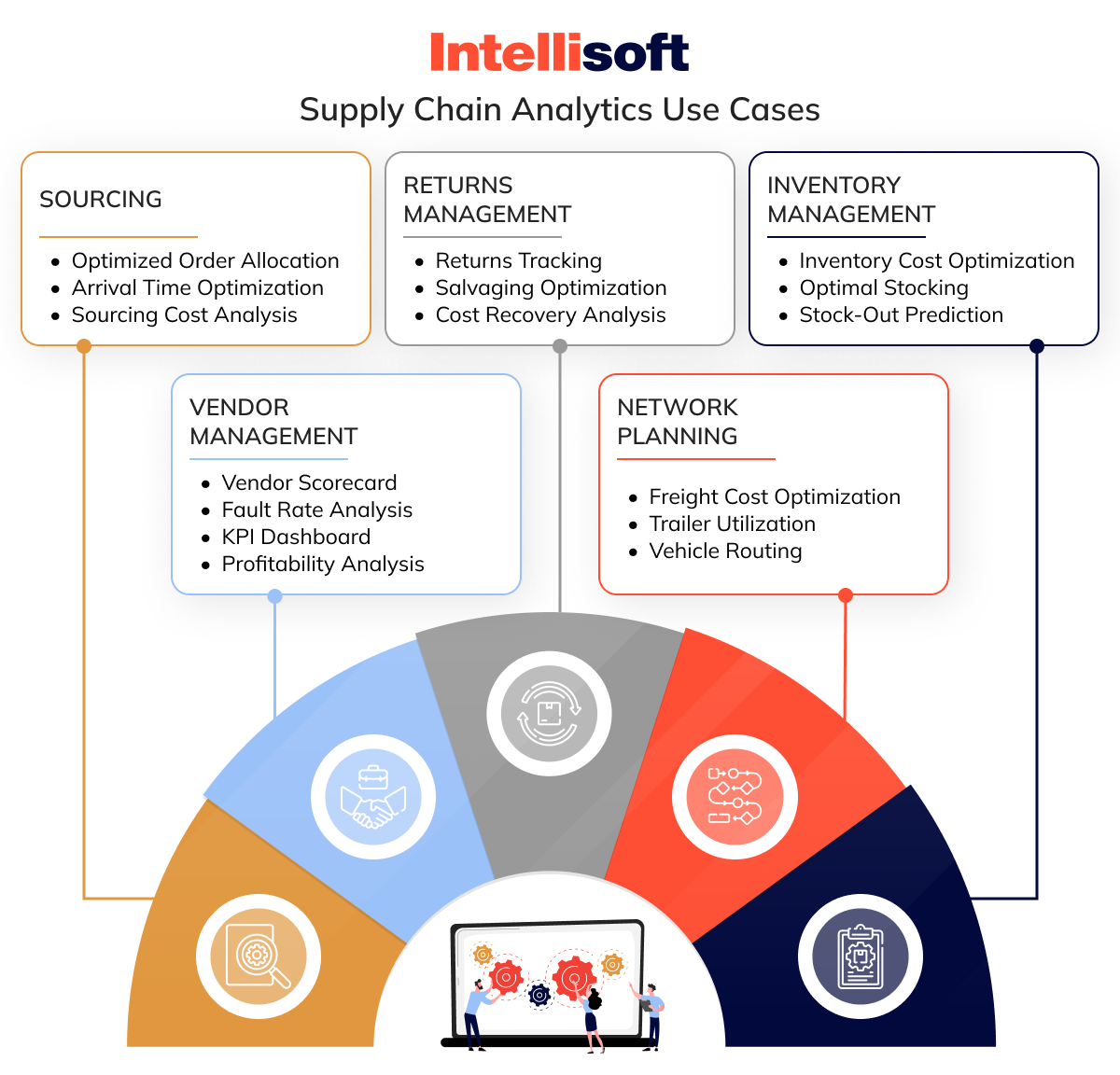

What are Real Examples of Leveraging Data Analytics in the Supply Chain?

Today, big data analytics in supply chain management has moved from just a theory to a solid practice. It’s not just talk – it’s a real game-changer. Companies around the world, in various sectors, are leveraging data analysis to revolutionize their logistics operations. Let’s dive into some concrete supply chain analytics use cases of how big data is utilized in different aspects of the supply chain.

Demand Forecasting

A critical aspect where data analytics shines is in demand forecasting. Companies utilize data analytics to predict future product demands with remarkable accuracy. This process involves a deep dive into historical sales data, current market trends, and external factors such as weather conditions or economic indicators.

Take Walmart, for example. This retail giant employs predictive analytics for supply chain to fine-tune inventory levels across its global network of stores. The goal? To seamlessly align inventory with consumer demand, avoid the pitfalls of overstocking or understocking. This approach ensures customer satisfaction and streamlines inventory management, a cornerstone of retail efficiency.

Route Optimization

Logistics is another sector reaping the benefits of data analysis, particularly in route optimization. Logistics companies are harnessing the power of data analytics to fine-tune delivery routes and schedules. This strategic move transcends mere efficiency – it reduces fuel consumption and delivery times and minimizes environmental impact.

UPS’s ORION (On-Road Integrated Optimization and Navigation) system is a prime example. This innovative system analyzes a wealth of data, from package delivery routes to real-time traffic conditions, to optimize delivery paths. The result? A significant reduction in fuel consumption, amounting to millions of gallons saved annually, is a testament to the power of data-driven logistics.

Supplier Performance Analysis

Data analytics extends its reach into the realm of supplier performance analysis. Here, companies analyze a spectrum of data related to their suppliers – from punctuality of deliveries and quality of goods to adherence to contractual agreements. This analysis is pivotal in pinpointing top-performing suppliers and strategizing risk mitigation for potential supplier failures.

A notable example is the automotive industry, with giants like Toyota leveraging data analysis for supplier performance analysis. This approach ensures robust, resilient logistics operations, which is crucial in an industry where the timely delivery of quality components is non-negotiable.

Inventory Management

In the field of inventory management, advanced analytics plays a vital role in helping companies maintain optimal inventory levels. This approach significantly reduces holding costs and decreases the risk of stockouts or excess inventory. Consider Nike, a global leader in the sportswear industry, as an example.

Nike utilizes data analytics to streamline its global inventory management system. This sophisticated use of analytics allows Nike to swiftly adjust production and distribution in response to fluctuating market demands, ensuring that their products are available where and when they’re needed, without the burden of overstocking.

Customer Sentiment Analysis

The voice of the customer has never been louder or clearer, thanks to data analysis. Companies can tap into valuable insights about customer satisfaction and preferences by analyzing data from social media, product reviews, and direct customer feedback. These insights are pivotal in shaping product development, marketing strategies, and fine-tuning supply chain operations.

A notable example is Coca-Cola, which leverages social media data analytics to identify emerging trends and adjust its logistics operations. By meeting evolving consumer demands, the company stays ahead in the beverage industry.

Risk Management

When you manage global supply chains, risk mitigation is paramount. Data analytics is extensively used to identify and evaluate potential risks, ranging from natural disasters and political instability to supplier bankruptcy. This analytical foresight enables companies to create robust contingency plans and diversify their supplier base to mitigate these risks.

Cisco Systems, a global technology leader, employs advanced analytics to monitor risks across its global supply chain network. By being proactive in responding to potential disruptions, Cisco maintains the resilience and reliability of its logistics operations.

Sustainable Operations

Sustainability is increasingly becoming a priority in supply chain management analytics, and data analytics is at the forefront of this green revolution. Companies are leveraging analytics to enhance the sustainability of their logistics operations. It helps optimize transportation routes to reduce carbon emissions, select eco-friendly materials, and minimize waste.

A prime example is H&M, which uses data analysis to support its ambitious goal of achieving 100% circularity and becoming climate-positive. By optimizing its supply chain for sustainability, H&M is not just reducing its environmental footprint but also setting a new standard in the fashion industry for eco-conscious operations.

These real-life applications of data analytics in the supply chain vividly illustrate its transformative power. Data analysis reshapes how companies operate their logistics operations, leading to more efficient, responsive, and responsible business practices.

What Are the Most Popular Data Analytics Solutions in the Supply Chain?

In today’s digitized world, the supply chain industry increasingly turns to sophisticated data analytics solutions to stay ahead. These solutions provide invaluable insights into various aspects of logistics operations management and enhance decision-making and operational efficiency. Let’s look into some of the most popular data analysis solutions revolutionizing supply chain operations.

SAP Integrated Business Planning (SAP IBP)

SAP Integrated Business Planning (SAP IBP) is at the forefront of supply chain planning. Known for its advanced analytics capabilities, SAP IBP encompasses a wide range of functionalities, including demand planning, inventory management, supply planning, and sales and operations planning. What sets SAP IBP apart is its exceptional integration capabilities, offering a comprehensive and holistic view of the logistics operations.

This integration of real time business intelligence in supply chain analytics enables organizations to make up to date decisions, promptly responding to changes in the market. SAP IBP clearly demonstrates the power of integrated, data-driven planning in modern supply chains.

Oracle Supply Chain Management (SCM) Cloud

Another heavyweight in the realm of supply chain advanced analytics is Oracle Supply Chain Management (SCM) Cloud. This suite is a powerhouse of analytics capabilities, spanning supply chain planning, procurement, manufacturing, and logistics. Oracle SCM Cloud distinguishes itself by leveraging artificial intelligence (AI) and machine learning to deliver deep insights into logistics operations efficiency, demand forecasting, and risk management. Its comprehensive approach enables businesses to optimize their logistics operations from end to end, harnessing the power of AI to stay agile and resilient in a competitive marketplace.

IBM Sterling Supply Chain Intelligence Suite

IBM Sterling Supply Chain Intelligence Suite, powered by AI, is a game-changer in predictive analytics for the supply chain. Its strength lies in its cognitive capabilities, which allow businesses to identify potential disruptions and optimize operations accordingly. IBM Supply Chain Intelligence Suite enhances visibility, improves forecasting accuracy, and bolsters risk management strategies. Harnessing the power of AI offers a proactive approach to managing logistics operations challenges, enabling businesses to stay one step ahead in a complex and ever-evolving landscape.

JDA Software (now Blue Yonder)

JDA Software, now known as Blue Yonder, specializes in AI and machine learning-based solutions for supply chain management. Blue Yonder’s analytics prowess covers a comprehensive range of logistics operations, including forecasting, planning, warehouse management, and fulfillment. Blue Yonder leverages advanced AI to provide businesses with intelligent supply chain insights, optimizing production and delivery processes. This technology ensures companies adapt quickly to market changes and customer demands, maintaining a competitive edge in their respective industries.

Infor Supply Chain Management

Infor Supply Chain Management is well-known for its tailored analytics and artificial intelligence features, designed to serve the unique requirements of various industries. This system delivers detailed insights into key areas of logistics operations, including demand planning, procurement, and logistics. With Infor’s industry-specific approach, companies can fine-tune their supply chains, ensuring they are aligned with their unique business requirements. This level of customization empowers businesses to optimize their supply chain processes, leading to improved performance and profitability.

Kinaxis RapidResponse

Kinaxis RapidResponse is a cloud-based supply chain analytics platform renowned for its supply chain planning and analytics capabilities. It offers a unique approach known as concurrent planning, which allows for simultaneous insights into logistics operations management, demand planning, and capacity planning. This concurrent perspective is crucial for enhancing responsiveness and agility within the supply chain. RapidResponse ensures that businesses can quickly adapt to changes in demand, supply, and market conditions, keeping their operations smooth and uninterrupted.

Tableau

While Tableau is not exclusively an SCA tool, it has gained widespread popularity for its visual analytics capabilities in supply chain management. Tableau helps companies transform complex logistics operations data into understandable and actionable visual insights. By visualizing data, businesses can easily identify trends, patterns, and outliers, making data-driven decisions more intuitive and effective.

Tableau excels in simplifying and clarifying complex data, helping businesses to more clearly and confidently manage the intricacies of their supply chains.

Microsoft Power BI

Microsoft Power BI is another versatile data visualization and analytics tool widely utilized across various industries, including logistics operations management. Power BI excels in integrating data from multiple sources, enabling companies to create comprehensive dashboards and reports.

These capabilities are crucial for better decision-making in supply chain management, as they provide a unified view of disparate data sets. The insights generated through Power BI help businesses optimize their logistics operations, identify efficiency gaps, and respond effectively to market trends and consumer demands.

LLamasoft Supply Chain Guru

LLamasoft Supply Chain Guru is a powerhouse in advanced analytics specifically tailored for supply chain design and decision-making. It offers a suite of modeling, simulation, and optimization tools that address the complex needs of logistics operations management. Companies use LLamasoft to reduce costs, improve service levels, and mitigate risks associated with logistics operations. Its ability to simulate various supply chain scenarios and outcomes makes it an invaluable asset for strategic planning and operational efficiency.

Qlik

Qlik stands out with its end-to-end data management and analytics solutions that have found significant applications in supply chain management. Qlik’s platform monitors Key Performance Indicators (KPIs), optimizes logistics operations, and enhances overall supply chain visibility and analytics. Its user-friendly interface and robust analytics features allow companies to thoroughly explore their logistics operations data, revealing insights that lead to improved decision-making and enhancements in operations.

The landscape of data solutions in supply chain management and analytics is diverse and dynamic. Each of these platforms brings its unique strengths, empowering businesses to navigate the challenges of supply chain management and analytics with more agility and insight.

Adopting Data Analytics in the Supply Chain with IntelliSoft

As we look at the big picture of supply chain analytics services, it’s clear that the adoption of data-driven strategies is no longer just an option, but a necessity for thriving in today’s competitive market. If you feel overwhelmed with a stream of raw data, IntelliSoft can step in as your trusted partner to bridge the gap between your current operations and a data-empowered future.

IntelliSoft takes the lead in integrating advanced data analytics into supply chain management. Our expertise lies in tailoring data analytics solutions that resonate with your unique business needs. We understand that each organization has its specific challenges and goals. Hence, our strategy is not a universal fit – rather, we concentrate on providing supply chain analytics consulting services and developing tailored solutions that are in sync with your specific business goals and operational structures.

Our team of skilled professionals excels in incorporating the most up-to-date supply chain analytics tools and technologies, including everything from predictive analytics for demand forecasting to AI-powered insights for managing risks. Whether you’re looking to optimize your inventory, streamline logistics, or gain a holistic view of your logistics operations, IntelliSoft has the technology and expertise to make it happen.

Embracing IntelliSoft’s data analytics integration services means investing in a future where data is not just numbers, but a strategic asset. With our support, you can unlock the full potential of your supply chain, adapting swiftly to market changes, anticipating customer needs, and staying ahead of the competition. Let IntelliSoft be the catalyst for your supply chain transformation. Reach out to us, and let’s march together towards a brighter, data-driven future.