In the dynamic world of inventory management, the line between chaos and control is as thin as a barcode! In this busy field, big and small retailers often find themselves at a crossroads: to pick from a sea of available off-the-shelf software solutions, or boldly build their own. Yes, it’s a serious task, with affordability often being the deal-breaker.

IntelliSoft is here to try to shine a light on this complex issue. We have been around a minute shy of two decades and know our way around developing streamlined systems for the logistics industry. Thanks to this experience, we’ve mastered the art of crafting bespoke software solutions that dance to the rhythm of your business’s unique beats.

Today, we’re not just talking theory; we’re rolling up our sleeves to show you how to build an inventory management system and choose the inventory management database design. This article is intended to become your playbook for stepping away from dependency on third-party software and into tailored, efficient supply chain operations.

Table of Contents

What are Common Challenges in Managing Inventory Without a System?

Efficient and effective inventory management is crucial for any business’s success, especially if you work in retail or manufacturing. However, managing inventory without a system can lead to several significant challenges.

Inaccurate Inventory Levels

Without a systematic approach, keeping accurate track of inventory levels is difficult. Relying on spreadsheets for inventory management can result in inaccuracies and discrepancies. Mistakes in data entry or counting during manual processes can distort the true representation of stock levels. As a result, you can face challenges in maintaining the right stock balance. Overestimation can lead to excess stock, while underestimation can result in stock shortages, impacting sales and customer satisfaction.

Delayed Decision-Making

Without a real-time IMS, decision-making is based on outdated or incomplete data. This delay can lead to missed opportunities and ineffective responses to market changes, ultimately impacting the business’s ability to compete effectively.

Stockouts and Overstocking

Without accurate demand forecasting, there’s a risk of underestimating demand and experiencing stockouts. Frequent stockouts can lead to lost sales and damage customer trust, while overstocking ties up capital in unsold stock and increases storage costs. Predicting the right amount of product to hold is a complex task that is almost impossible without the insights provided by a management system.

Increased Holding Costs

Holding excessive inventory leads to additional costs, including storage, insurance, and obsolescence risks. Inefficient use of storage space can further contribute to increased holding costs. These costs can significantly impact the financial health of a business, reducing overall profitability.

Order Fulfillment Challenges

Manually processing orders is prone to errors and inefficiencies. It may lead to picking, packing, and shipping errors, impacting order accuracy. Inefficient processes can result in delayed order fulfillment times. Without a system, tracking orders, managing back-orders, and ensuring timely delivery can become complicated and cumbersome, leading to customer dissatisfaction.

Lack of Historical Data

Operating without historical inventory data hinders your ability to forecast demand, analyze trends and customer preferences, and make informed purchasing decisions. This lack of data makes optimizing stock levels and responding to market demands challenging.

Difficulty in Compliance

To meet industry standards and regulations, automated systems in inventory management are crucial. Manual methods often increase errors and the risk of not complying with regulations, potentially leading to legal and financial issues. Using automated tools for inventory management helps ensure you adhere to industry rules and regulations.

Supplier Management Issues

Managing suppliers effectively needs precise and current information, which is difficult with manual methods. Manual interactions with suppliers can cause delays in ordering and restocking. Not being able to assess supplier performance can weaken your position in negotiations. Key challenges in supplier management include monitoring their performance, handling lead times, and negotiating terms, all of which are vital for a smooth-running supply chain.

Manual Workload and Labor Costs

Manual inventory management demands significant labor, leading to increased labor costs. It requires extensive manpower for tasks such as data entry, stock verification, and order processing, which could be streamlined with an automated system. Resolving errors and discrepancies consumes additional resources.

Security Concerns

Manual inventory systems are more vulnerable to errors, theft, and data breaches. A lack of robust security measures in manual systems can lead to significant losses and compromise sensitive business information.

Adopting an IMS is a key solution to these issues, offering automated processes, immediate tracking capabilities, and analytics-based insights. This approach leads to enhanced overall effectiveness and precision in inventory control.

What is an Inventory Management System (IMS)?

An IMS is a technological solution for overseeing and organizing your inventory. It provides critical real-time visibility into stock levels, movements, and product availability. This system combines software and hardware components to track and manage items efficiently from acquisition to sales.

Types of Inventory Systems

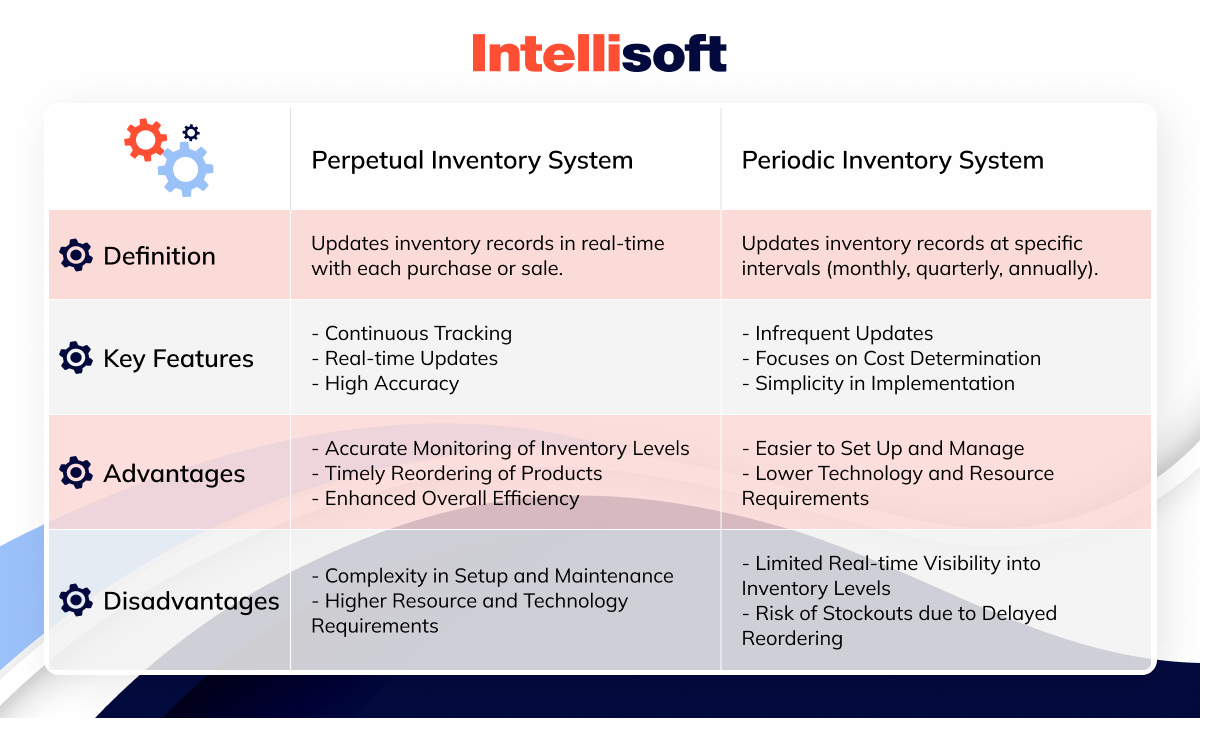

Inventory systems are essential for modern business operations, and they mainly come in two types: perpetual and periodic. Each type offers a different approach to inventory tracking and management.

A perpetual inventory system continuously updates inventory records in real-time as goods are bought and sold. This approach provides an ongoing, accurate view of current stock levels, ensuring businesses have the most up-to-date information on their inventory status.

Key Features:

- This system constantly tracks stock levels.

- Inventory records are updated in real-time with each transaction.

- Offers a highly accurate representation of current stock.

Pros:

- Allows businesses to understand their stock levels precisely.

- Aids in timely product reordering, preventing stock shortages.

- Minimizes the probability of errors and enhances the efficiency of overall management.

Cons:

- More complex to set up and maintain than other systems.

- Implementation may require more resources and advanced technology.

In contrast, a periodic inventory system updates stock records at set intervals, such as monthly, quarterly, or annually. This system tracks transactions and calculates the cost of goods sold within the specified period without continuously monitoring actual stock levels.

Key Features:

- Updates inventory records infrequently at predetermined intervals.

- Primarily used for calculating the cost of goods sold.

- Typically, it is easier to implement and maintain.

Pros:

- More straightforward setup and management, ideal for smaller businesses.

- Less reliant on advanced technology and resources.

Cons:

- Does not provide real-time insights into stock levels.

- Potential for delayed reordering decisions, which can lead to stock shortages.

Both systems have their own methods and advantages. The right choice depends on what a business needs and can do. Picking the best database for inventory management is important because it can really affect the efficiency and scalability of your system.

Main Functions of an Inventory Management System

An IMS comes with key features essential for managing inventory effectively. These features simplify the process of tracking stock, improve precision, and offer important data for making business decisions.

Stock tracking is the foundation of any IMS. It allows for real-time monitoring of inventory levels, movements, and locations. This feature helps maintain optimal stock levels, avoid overstocking or stockouts, and ensure accuracy.

Order management functionality involves managing the entire lifecycle of customer orders. It includes order creation, tracking, fulfillment, and delivery. Effective order management ensures timely processing and customer satisfaction.

Product Information Management (PIM) centralizes and organizes all product-related data. This data includes descriptions, specifications, pricing, and supplier data. PIM ensures consistency and accuracy of product information across various channels.

IMS helps set reorder points – the stock level at which a reorder is triggered. It also assists in forecasting future needs based on historical sales data, trends, and seasonal variations, optimizing stock levels.

Supplier management functionality involves handling supplier relationships, including tracking supplier performance, managing contracts, and negotiating terms. Effective supplier management ensures a steady supply chain and can lead to cost savings.

Integration with barcode scanning and RFID (Radio-Frequency Identification) technologies enhances the efficiency of inventory tracking. It enables quick scanning of items for various processes like receiving, moving, or counting stock.

An IMS provides comprehensive reporting and analytics capabilities. This functionality includes generating reports on stock levels, sales, order status, and more. Analytics help in gaining insights for making informed business decisions.

For businesses with multiple warehouses or stores, IMS offers multi-location support. This functionality allows for the seamless management of inventory across different locations, ensuring a coordinated approach to stock management.

IMS can send alerts and notifications for critical events such as low stock levels, order fulfillment status, or shipment delays. This feature helps in proactive inventory management.

User access control in IMS enables the management of user access and permissions to different parts of the system. This feature restricts access to authorized personnel only, ensuring the security and integrity of sensitive data.

Integration with other business systems like ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), or e-commerce platforms is crucial for a holistic approach to business management.

An audit trail is maintained by an IMS for all transactions and system changes. This is essential for regulatory compliance and internal audits. It ensures accountability and traceability of all inventory-related activities.

These core functionalities collectively make an IMS a powerful tool for businesses, enabling efficient and effective stock control and management.

Inventory Management System Architecture

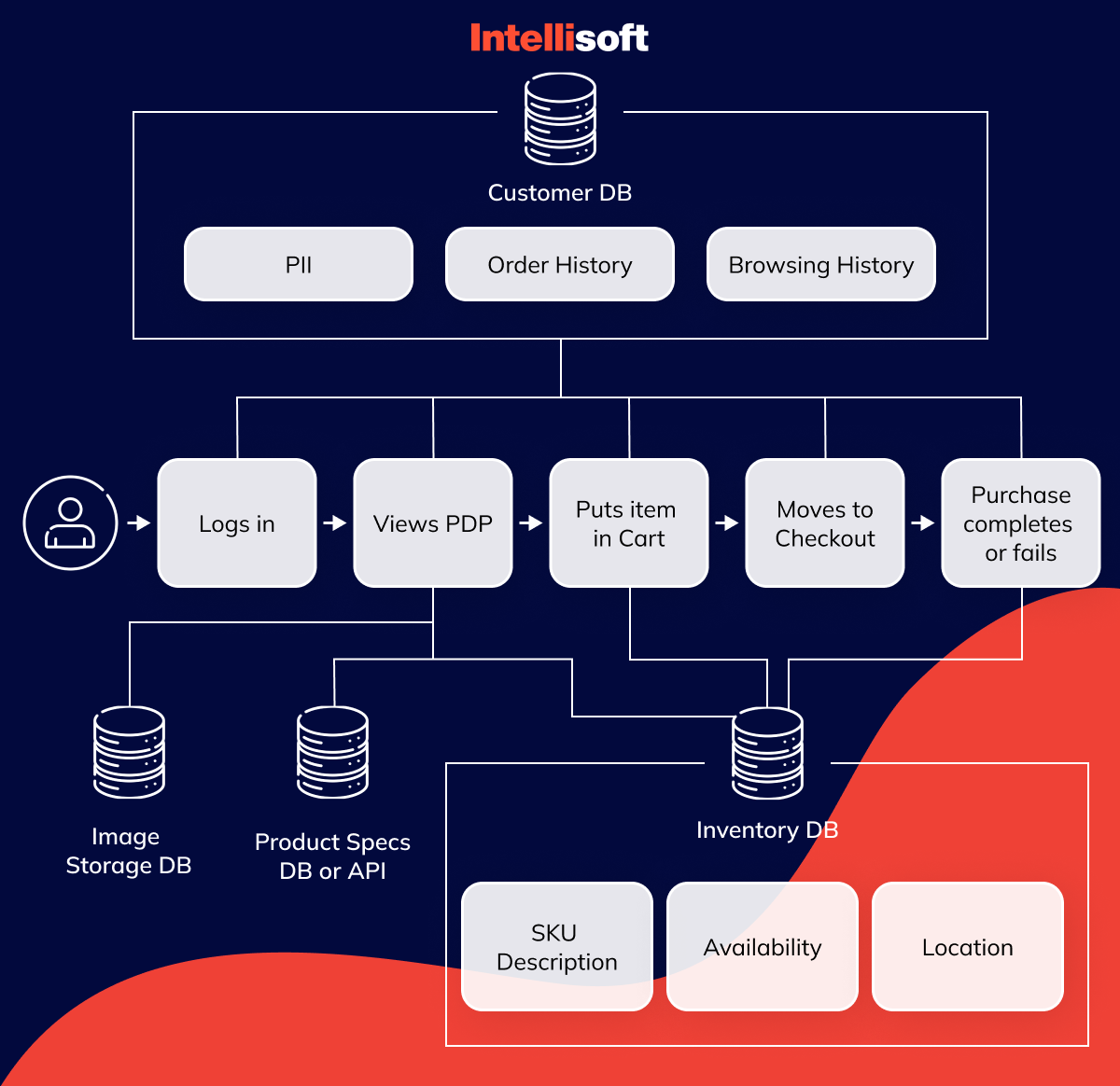

The design of an IMS is vital for maintaining an organized, efficient, and scalable operation, especially in the context of online retail. The diagram below illustrates the fundamental components of IMS architecture and how they interact throughout the customer purchasing process.

In the center of the diagram, you can see the sequential actions of an online shopper, from logging in to potentially completing a purchase. These actions are the touchpoints where the system interfaces with the user.

A customer database is a repository for user-related information. It houses Personally Identifiable Information (PII), order history, and browsing history, ensuring that customer details are readily available for personalization and order tracking.

The core of the IMS is the inventory management database. It contains detailed product metadata such as Stock Keeping Unit (SKU) descriptions, availability, and the location of the stock within warehouses or stores. It acts as the “source of truth” for inventory management, maintaining the integrity and accuracy of stock levels.

The image database stores visuals, including product images that appear on Product Description Pages (PDPs), search results, and other customer-facing platforms. These images are essential for the online shopping experience, providing customers with the visual details they need to make purchase decisions.

A Product Specs Database/API component provides detailed specifications for products on PDPs. Often sourced from third-party providers, it contains information that the retailer may not manage but is integral to informing customers about product features.

As the user progresses through their shopping journey, the system performs various actions:

- Login triggers a query to the customer database to authenticate and personalize the user experience.

- Viewing PDPs demands simultaneous queries across the inventory, customer, image, and product specs databases to assemble all the relevant data for the product being viewed.

- Adding to the cart often involves temporarily marking the item as sold in the inventory management database to reserve the stock for the customer, which then requires real-time updating based on whether the purchase is completed or the reservation timer expires.

- Checkout engages the customer database again to retrieve necessary user information for the transaction.

- Purchase completion finalizes the inventory management database update, either deducting the stock if the sale is successful or reinstating it if it fails.

Efficient management of these databases is a complex task. This complexity highlights the importance of selecting the right inventory management database tools and technologies to ensure reliability and scalability in inventory management.

Related readings:

- Barcode Scanning for Ultimate Inventory Digitalization

- How to Develop Logistics Management System: Timeframe, Tech Stack, and Costs

- How Predictive Analytics Solutions Are Benefitting Supply Chain

- Machine Learning in Logistics Industry: Benefits and Use Cases

- Warehouse Automation Systems: Revolutionizing Supply Chains for Unprecedented Efficiency

How to Create an Inventory Management System: Step-by-Step

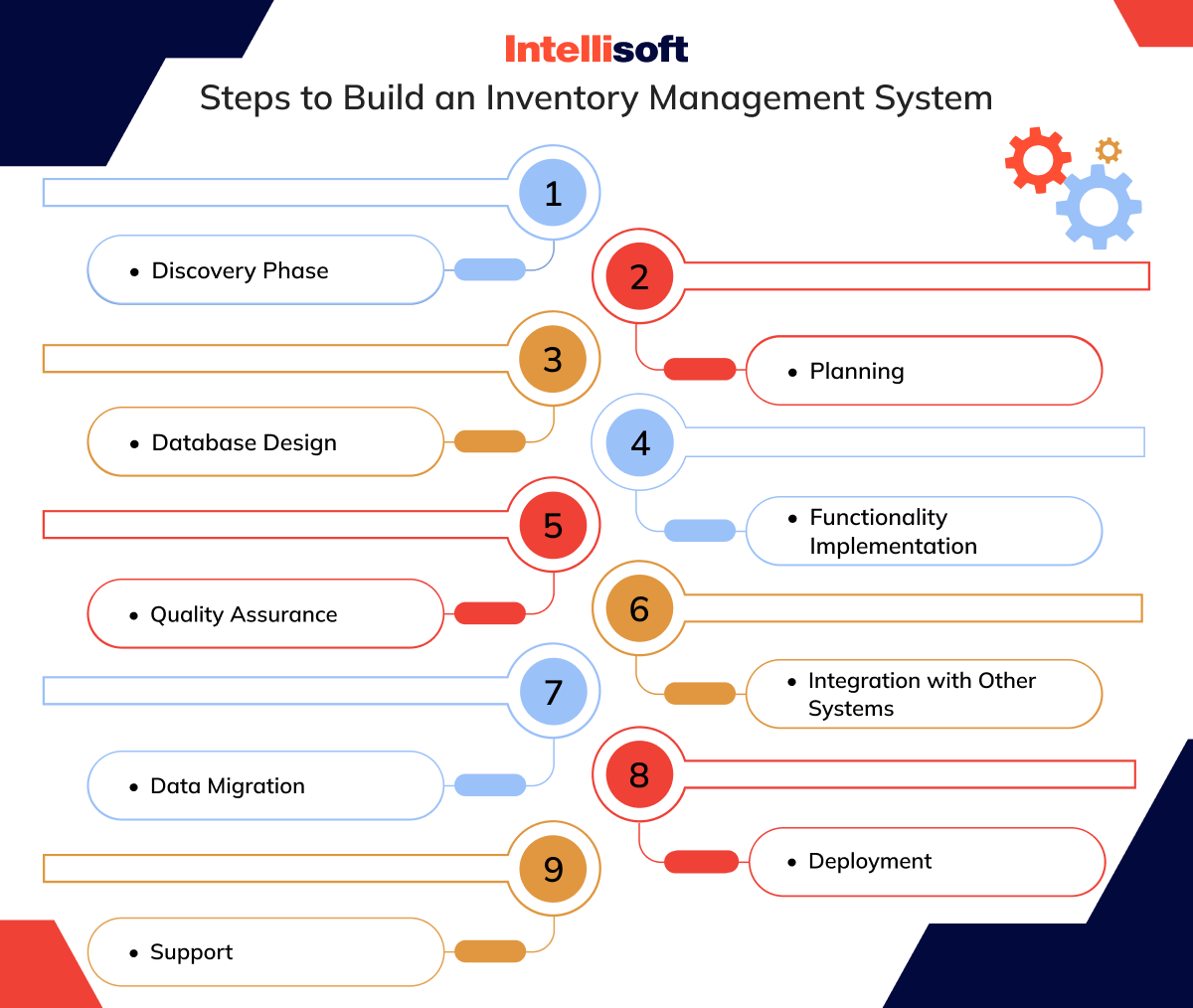

Creating an IMS is a structured journey that demands careful planning and execution. Here’s a step-by-step guide to get you started.

Step 1. Discovery Phase

The first step is the discovery phase, where the groundwork for your IMS is laid out. This stage involves eliciting both functional and non-functional requirements, defining user roles, and determining necessary integrations with other systems like ERP, CRM, WMS, POS, and accounting systems. It’s also the phase where you decide on the specifics of your inventory system: whether it will be software-only or incorporate hardware components like barcode or RFID scanners.

The discovery phase also includes outlining the high-level architecture of the solution, establishing major components, and the interactions between them. At this stage, prototyping for UX and UI begins, shaping the user’s journey through the IMS. Furthermore, it’s essential to compose an optimal tech stack, selecting proven frameworks, low-code platforms, and pre-built components to streamline development.

Step 2. Planning the Project in Detail

After laying the foundation, the next step is to meticulously plan the project. This stage includes outlining the scope of work and its duration, identifying potential risks, and strategies to mitigate them. Calculating the expected Total Cost of Ownership (TCO) and Return on Investment (ROI) is critical to ensure the project’s financial viability. Defining clear milestones, objectives, and KPIs will keep the implementation focused and measure progress against the business goals.

Step 3. Designing the Database Schema

Designing a robust database schema is crucial for a functional IMS. It’s about creating a blueprint for the database structure, detailing tables for products, categories, suppliers, and transactions. Each table will store specific data types and establish relationships, such as one-to-many or many-to-many, to maintain data consistency and prevent redundancy. Ensuring data integrity through constraints and normalization is also vital to avoid anomalies and maintain the reliability of your inventory system. A well-structured database for inventory management ensures accurate tracking of stock levels, enhances reporting capabilities, and supports informed decision-making in supply chain operations.

Step 4. Implementing System Functionality

With the database schema in place, you move on to implementing the IMS’s system functionality. This step involves developing and integrating features allowing efficient inventory entry and tracking, such as product entry forms and real-time updates. It is crucial to set up alerts for low stock levels or expiring products to prevent stockouts and reduce waste.

Additionally, incorporating barcode scanners and RFID technology can greatly enhance the system’s efficiency, accuracy, and user experience by providing faster and more accurate data entry and product tracking.

Step 5. Running QA

The next step in building an inventory management system is to run Quality Assurance (QA) procedures. It is a critical stage where the software is thoroughly tested to validate its quality. The QA team will look for bugs and other issues that could hinder performance. This process ensures that the software is reliable and ready for integration with other systems before going into production.

Step 6. Integrating the Software with Other Systems

Integration is a key step that follows the design stage of the system. It involves implementing and testing the integration patterns and procedures with other essential business systems and BI solutions. This step is crucial for enabling comprehensive inventory reporting and visualization of inventory-related data, ensuring the IMS works seamlessly within the existing IT ecosystem.

Step 7. Migrating Inventory Data

Migrating inventory data requires a well-thought-out strategy and carefully crafted scripts to automate the process. Data mappings are defined to translate data from the old system to the new one. The data is then extracted from legacy systems or spreadsheets, validated for quality, and any issues like lost or corrupted data are addressed. Once cleaned, the data is loaded into the new inventory database, undergoing verification procedures to guarantee accuracy and consistency.

Step 8. Deploying the Inventory System

Deployment of the IMS is executed in stages to ensure all components function correctly:

- Stage 1 involves configuring the software infrastructure and setting up backup and disaster recovery protocols. Security mechanisms are established, including authorization controls and protections against cyber threats. Additionally, any required hardware, like barcode scanners or RFID equipment, is installed and calibrated. The system is then deployed to a selected facility for a pilot run, typically lasting around two weeks.

- Stage 2 is where the system is monitored under real-life conditions to address any emerging issues or change requests, particularly those related to hardware integration. The pilot operation generally lasts from one to two months.

- Stage 3 starts when the final version of the system is rolled out across all targeted facilities. The duration of this phase can vary, typically around two months, but may increase depending on the complexity and number of facilities.

Step 9. Running After-Launch Support

Post-deployment, continuous user support is provided at this stage. The system undergoes regular updates and functionality enhancements driven by evolving business needs and user feedback. This stage includes enabling more types of inventory reports and UI improvements.

For systems with hardware components, such as barcode scanners, RFID, or computer vision technologies, ongoing maintenance is crucial and often managed in partnership with the hardware vendors. This approach ensures that the hardware is kept in optimal condition and any defects are promptly addressed.

Now you know how to build an inventory management system, but creating an intricate IMS demands attention to detail, a clear understanding of your business needs, and a commitment to ongoing support and enhancement. When executed correctly, an IMS becomes an invaluable asset to your organization, providing the precision, efficiency, and scalability needed to thrive in today’s competitive marketplace.

IMS Development Team Structure

Developing a cutting-edge Inventory Management System is a complex undertaking that demands the collective effort of a group of experts, each contributing their specialized skills and experience to the project. Here’s a breakdown of the roles that form the backbone of an IMS development team:

Project Manager

The Project Manager guides the IMS project towards its objectives within the allocated budget and timeline. This role involves prioritizing work scope, monitoring task execution, and ensuring seamless coordination among team members. The Project Manager also acts as the primary communication link between the development team and the client, reporting progress and aligning on objectives.

Business Analyst

The Business Analyst is the bridge between business needs and technical solutions. They delve deep into the functional and non-functional requirements, uncover technical limitations, and define necessary system integrations. Their analysis shapes the foundation of the IMS, ensuring that it aligns with business objectives and solves the right problems.

Solution Architect

The Solution Architect designs the blueprint for the entire IMS. They determine how various system components will work together and establish integration points with other essential systems such as ERP, CRM, and accounting software. Their architectural design is crucial for a scalable, robust, and efficient IMS.

UX Designer + UI Designer

UX and UI Designers are the creative minds focused on the system’s usability. They conduct user research, craft user flows, create prototypes, and collect user feedback. Their mission is to ensure the IMS is functional, intuitive, engaging, and providing a seamless experience for the end-users.

Software Engineers

Software Engineers are the builders. They are responsible for developing the front end and back end of the IMS, ensuring that every line of code contributes to a solid and secure system. Their role also involves integrating the IMS with other business systems, a critical step for a fully cohesive IT environment.

QA Engineer

Last but not least, the QA Engineer is the guardian of quality. They design and implement a comprehensive test strategy and plan, crafting test cases to cover every possible scenario. Their meticulous validation process is essential to ensure that the IMS is reliable, performs well under various conditions, and meets the quality standards before it goes live.

Together, these roles form a dynamic team capable of delivering a high-quality Inventory Management System tailored to meet your company’s specific needs. As a team, they can ensure the system is built to last and evolve with your business over time.

Cost to Develop an Inventory Management System

When you are considering launching the development of a custom inventory management system, cost is always one of the primary concerns. This investment can vary depending on the complexity and scale of the system required.

For a solution of average complexity, which includes essential features like stock tracking, order management, basic reporting, and straightforward integrations with existing systems, the costs typically range between $90,000 and $250,000. This tier of system would suit small to medium-sized businesses looking to streamline their inventory processes without extensive customization or advanced analytics.

However, for larger organizations that require a more sophisticated solution, the costs escalate. A large-scale IMS, complete with hardware integrations (such as barcode scanners RFID technology), advanced inventory analytics, custom UI/UX design, and complex integrations with multiple systems, can set you back anywhere from $250,000 to $1,400,000. This kind of system offers comprehensive functionality, extensive automation, and deep insights into inventory data, which are essential for large businesses with intricate inventory management needs.

It’s important to note that these figures are averages, and various factors, such as the choice of technology stack, geographical location of the development team, and the specific business requirements, can influence the actual cost. Also, post-deployment costs such as maintenance, updates, and training should be considered when budgeting for an IMS.

Investing in an IMS can significantly enhance operational efficiency and provide a strong return on investment in the long run. Still, it requires careful financial planning and consideration of the total cost of ownership.

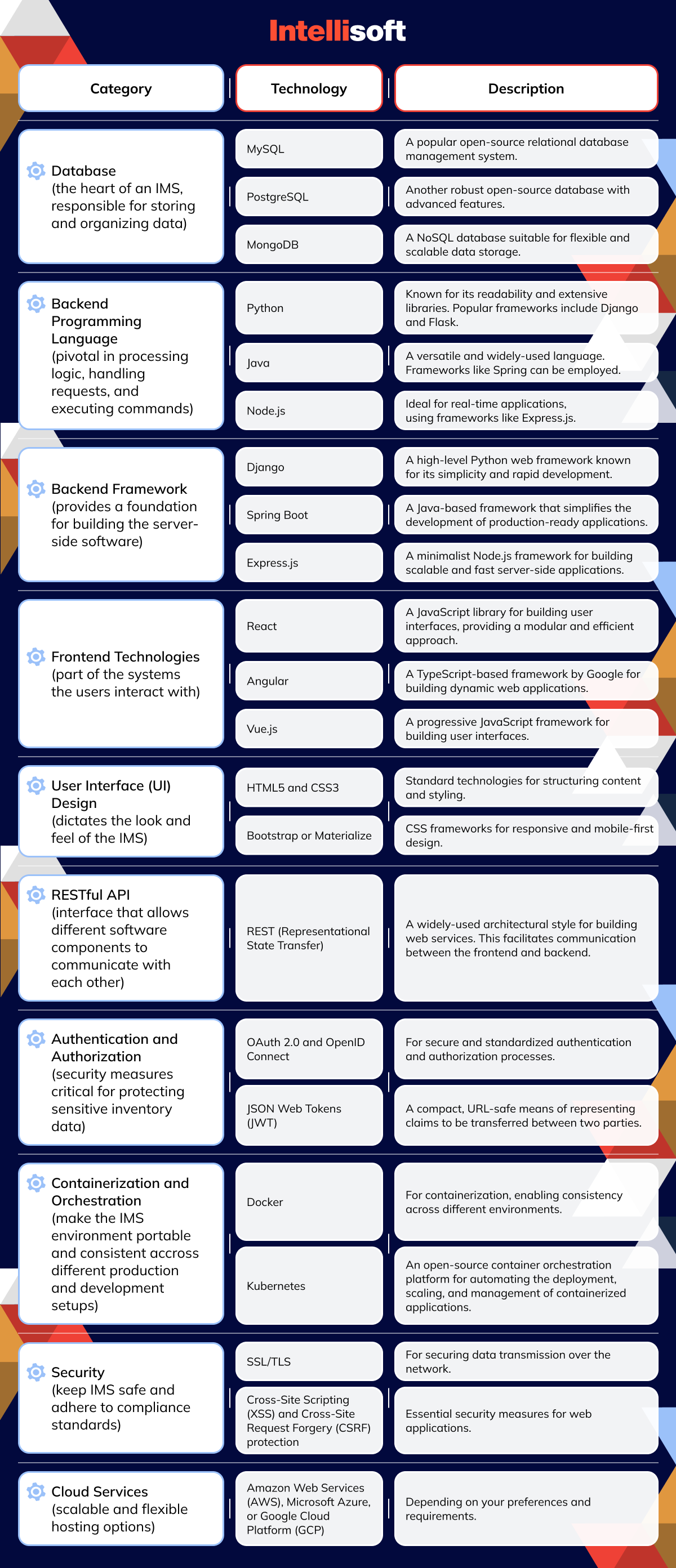

Inventory Management System Tech Stack

The tech stack for an inventory management system (IMS) is a layered structure of technologies that empower the system’s functionality, usability, and efficiency. It comprises a combination of databases, programming languages, frameworks, and various technologies that work harmoniously to deliver a robust IMS. Here’s a breakdown of the typical tech stack components:

Choosing the right tech stack is vital for the success of your IMS. It must be tailored to the specific needs of your organization, considering factors such as scalability, security, and budget. The components listed in the table can form a strong foundation for a functional, future-proof system.

Conclusion

Due to the complexities of modern business operations, a well-designed inventory management system becomes necessary for achieving efficiency. A well-implemented IMS isn’t just about keeping track of stock; it’s about unlocking the potential for optimized operations, cost savings, and better customer satisfaction.

The journey doesn’t end with deployment. Like any robust ecosystem, an IMS evolves, adapting to new challenges and business landscapes. Here lies the value of partnering with an experienced development company like IntelliSoft. We provide full-stack web and app development services to create custom software solutions that resonate with your unique business needs.

We are committed to providing businesses with powerful tools that help drive success. Whether you’re looking to build a new IMS or enhance an existing one, contact us, and IntelliSoft will become your trusted partner to elevate your inventory management to the next level.