Experts will tell you that modern logistics systems are constantly evolving, and this tool is a superhero. It is not surprising, as the global WMS market is expected to reach $10.5 billion by 2030, with a CAGR of 19.0% between 2023 and 2030.

This growth is driven by expanding global economies, pushing sectors like healthcare, manufacturing, and retail to seek efficient operational methods to enhance output and meet customer expectations. Transportation management systems (TMS) are the leading stars in 56% of WMS usage.

Logistics companies face the ever-changing tides of product markets and shipping calendars and actively strive to overcome them. But how to do this smoothly and let your business live long and prosper? The answer is Warehouse Management System integration.

In this article, you’ll learn how to integrate WMS into your enterprise system. Our 15 years of experience in logistics ensures a unique blend of expertise and innovation. So, what is a WMS? Let’s see how it can be the secret weapon in your business arsenal!

Table of Contents

What Is a Warehouse Management System?

When it comes to managing inventory and fulfilling orders, among other warehouse operations, the WMS (Warehouse Management System) acts as the central controller, carrying out these duties with remarkable accuracy and efficiency. It guarantees a streamlined, efficient, and error-free operation by supervising the full route of stocks from their arrival in the warehouse until their shipment.

Understanding Warehouse Management System Integration

Time is of the essence in the warehousing industry and every minute counts towards ensuring efficient and quick operations. However, to maintain this level of productivity, businesses must also have a deep understanding of proper stocking management practices.

A crucial element in achieving this is the integration of Warehouse Management Systems (WMS), which can significantly enhance warehouse operations’ overall efficiency and accuracy. Let’s delve deeper into the world of WMS integration and explore the benefits it can provide to businesses.

Significance of WMS Integration

Warehouse Management System WMS integration can streamline your business operations by effectively breaking down silos and promoting seamless collaboration across different departments. With the implementation of WMS Integration, you can achieve a harmonious relationship between all the essential technologies to ensure the smooth functioning of your business. It, in turn, can help you optimize your warehouse operations, reduce errors, and enhance overall efficiency.

Types of integrations available

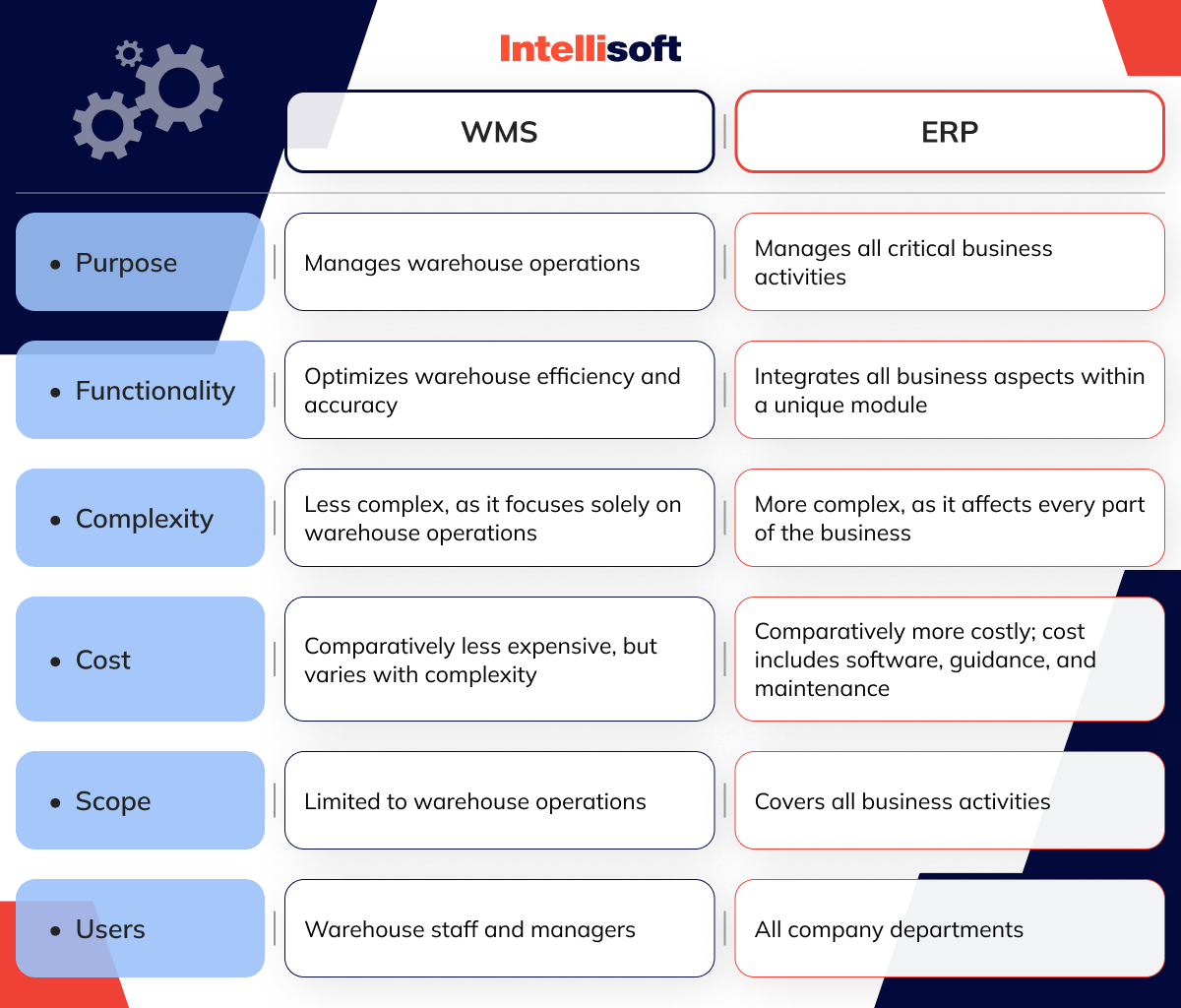

- ERP Integration. Integrating a Warehouse Management System (WMS) into an ERP system enables seamless information exchange between warehousing and various business segments. These segments encompass finance, human resources, manufacturing, and supply chain management. Such a merger guarantees uniformity in data, minimizes the need for manual data input, and enhances decision-making processes through the availability of instantaneous information. The enhancements include better inventory control, procurement processes, and financial report accuracy.

- eCommerce Integration. This connection links the Warehouse Management System (WMS) with various eCommerce platforms. It is a crucial feature for companies that manage both physical shops and digital sales outlets. The eCommerce connection is crucial for synchronizing inventory levels, optimizing freight management, and ensuring timely order fulfillment. Providing accurate stock information and faster delivery enhances customer satisfaction.

- Order Management Integration. The process involves connecting the Warehouse Management System (WMS) with the platforms that handle order processing and fulfillment. This integration allows for a unified view of orders from various sales channels, enhances order precision, and simplifies the fulfillment process. It enhances the efficiency of picking, packing, and shipping activities, thereby improving the standard of customer service.

Advantages of integrating WMS with other systems

Here are the key benefits of a warehouse management system that make business operations smooth:

- Increased Visibility. Integrating a WMS (Warehouse Management System) enables live monitoring of inventory, orders, and cross-platform deliveries, offering a complete view of business operations. This access to extensive data sets empowers companies to forecast demand and regulate inventory more accurately, minimizing the chances of understocking or overstocking. The immediate insight into inventory and order requirements improves customer interactions and delight.

- Enhanced Precision and Productivity. When systems automatically share data, it minimizes the need for manual data entry and reduces the chance of errors occurring. Warehouse managers can increase productivity by optimizing labor and equipment usage through the use of reasonable information and integration. The integration streamlines picking, packing, and shipping processes to enhance efficiency and minimize errors.

- Optimized Supply Chain. Real-time data on inventory levels helps maintain optimal stock, avoiding excess and shortages. Sharing information with suppliers can lead to more synchronized production and delivery schedules, reducing lead times. An integrated system provides the agility to respond swiftly to market changes, supply chain disruptions, or consumer requirements.

Strategic, Data-Informed Choices. Access to comprehensive data across systems enables better analysis and more informed strategic decisions. Integrating data allows for monitoring of key metrics, aiding ongoing improvement. Analyzing patterns and trends within the data can help predict future needs and plan accordingly.

Integrating a WMS with other systems streamlines warehouse processes and enhances the business’s efficiency and responsiveness. This move helps companies adapt to the ever-changing business environment, meet customer expectations, and remain competitive. Therefore, these benefits of a warehouse management system are critical for further company success.

Related readings:

- Barcode Scanning for Ultimate Inventory Digitalization

- Freight Management System Development with IntelliSoft: Ultimate Guide

- How to Develop Logistics Management System: Timeframe, Tech Stack, and Costs

- Last-Mile Delivery Software Development: a Complete Guide

- Warehouse Automation Systems: Revolutionizing Supply Chains for Unprecedented Efficiency

Key Components of Warehouse Management System Integration

Incorporating a Warehouse Management System (WMS) into your business framework is a critical step toward streamlining your operations and guaranteeing smooth inventory and order fulfillment management. To successfully integrate your business, there are certain vital elements that you must take into account. These components are crucial in ensuring that your business can run smoothly and meet your customers’ needs with minimal issues.

Data synchronization between WMS and other systems

Integrating a WMS (Warehouse Management System) is crucial to maintaining a smooth and consistent data flow. This synchronization enables seamless information exchange between the WMS and ERP systems, suppliers, and customers. With this integration, inventory levels, order status, and financial transactions are updated in real-time for all parties, ensuring consistency and accuracy and avoiding discrepancies. It also helps streamline the supply chain processes, improving efficiency and better customer satisfaction.

Real-time visibility and tracking of inventory

Fully integrated Warehouse Management Systems provide real-time visibility and tracking of inventory, which is essential for efficient warehouse management. This procedure involves regularly updating inventory status information, such as data on available stock, goods in transit, and orders awaiting fulfillment. Implementing barcode scanning or RFID tracking improves inventory control by delivering instant data on inventory movements. Advanced analytics help businesses understand inventory trends and make informed decisions based on real-time data.

Streamlining order fulfillment processes

Streamlining order fulfillment is another critical aspect of Warehouse Management System (WMS) integration. This approach helps automate the process of receiving and shipping orders to minimize human errors, speed up operations, and enhance overall efficiency. It is crucial to focus on refining the picking and packing stages to ensure that orders are handled quickly and accurately. Besides, integrating the WMS (Warehouse Management System) with various shipping carriers can further streamline the dispatch and delivery process. This integration allows for better tracking and management of orders, resulting in more efficient operations.

Automation of tasks for improved efficiency

Integrating automation into the WMS (warehouse management system) enhances business efficiency by lowering the need for manual data entry and recovery. This method minimizes errors and saves valuable time. Advanced technologies like robotics and Automated Guided Vehicles (AGVs) are increasingly employed for repetitive tasks, such as inventory transportation. Furthermore, intelligent warehouse technologies, including IoT devices and sensors, are crucial in predictive maintenance and optimizing warehouse operations. When combined, these technologies contribute towards a more efficient, responsive, and modern warehouse management system.

What is a WMS? It is easier than a newbie can consider at first. This tool enhances accuracy, efficiency, and customer satisfaction as it is a vital part of supply chain and business processes.

Steps to Successful Warehouse Management System Integration

Integrating a Warehouse Management System (WMS) is a significant undertaking for any company, and it requires careful planning to ensure a successful outcome. The process involves several critical steps to be taken for a smooth transition to the new system.

Hire Development Team

In today’s fast-paced digital landscape, businesses often need to scale up their development capabilities quickly and efficiently. Companies should educate themselves on hiring development team practices and the benefits of a warehouse management system.

There are several advantages to outsourcing to specialist groups like IntelliSoft, which might be essential for accomplishing a project.

- Cost-Effectiveness. One of the primary advantages of outsourcing development is the potential for significant cost savings. Outsourcing companies typically operate in regions with lower labor costs, enabling them to offer competitive pricing for their services. This money-saving model allows businesses to access top-notch development work without the overhead costs associated with in-house teams (for instance, pay, perks, and place of employment).

- Access to a Wider Talent Pool. Outsourcing opens the door to a global talent pool. Outsourcing companies employ diverse professionals with varied skill sets and expertise. It means businesses can find the exact skill sets needed for WMS warehouse management system development without being limited by geographical or local market constraints. Outsourcing can give access to the special capabilities required for project success, whether it’s new development techniques or specialized technological knowledge.

- Flexibility with Time and Material Model. Outsourcing companies’ time and material model is particularly beneficial for projects where the scope and requirements are flexible and can evolve. This model provides the flexibility to adjust resources and timelines as the project progresses and allows for more dynamic engagement with the development team, adapting quickly to changes and new insights as the project unfolds.

- Focus on Core Business Activities. Businesses no longer have to get distracted by the intricacies and demands of software development to concentrate on their core competencies, thanks to outsourcing development. While internal resources can take a new direction to improve strategic development and innovation, WMS can enhance efficiency and productivity in other company areas.

Outsourcing warehousing technologies integration to a development team brings cost savings, access to a global talent pool, flexibility in project management, and the ability to focus on essential business features. This is a strategic decision for companies looking to remain competitive and efficient in the marketplace, while improving their software development skills.

Assessment of Current System and Requirements

System Evaluation

- Perform an in-depth review of your existing warehouse management systems and associated processes.

- Identify the strengths, potential areas of improvement, and key advancements your business can achieve through this integration.

Set Clear Goals

Clearly define the objectives you aim to achieve through the integration. These may encompass:

- increasing inventory precision

- improving order processing activities

- boosting overall logistics management effectiveness.

What is WMS system software? Experts suggest that this tool aids businesses in setting definitive objectives due to its integration.

Selection of Compatible Integration Solutions

Identify Integration Needs

- Ascertain the specific organizational systems that require linkage with your Warehouse Management System (WMS).

- Potential candidates often include Enterprise Resource Planning (ERP) systems, eCommerce interfaces, and Order Management Systems.

Research Integration Options

- Explore the market to find integration solutions that align with your needs.

- Essential factors to consider are the WMS scalability, flexibility, and the ease of its integration process.

Implementation Best Practices

Create an Elaborate Strategy

- Develop an implementation plan describing the precise activities, schedules, and given roles.

- A thoroughly prepared plan is vital for a smooth WMS (warehouse management system) integration and for reducing interruptions to routine business functions.

Data Mapping and Standardization

- Ensure the uniformity of data formats and architectures among WMS systems.

- Develop a strategy for data mapping to ensure seamless data transfer and to decrease the likelihood of errors throughout the integration phase.

Testing and Validation Processes

Conduct Thorough Testing

- Before full-scale deployment, conduct rigorous testing to identify and address potential issues.

- Test the warehouse management cloud system in various scenarios to ensure it performs as expected under different conditions.

Continuous Monitoring and Optimization

Monitoring Performance Metrics

- Establish key performance indicators (KPIs) to measure the success of the integration.

- Regularly monitor these metrics to identify improvement and optimization points.

Iterative Optimization

- Continuously gather feedback from users and stakeholders for further integration setup updates that optimize performance and address evolving business needs.

Common Challenges in WMS Integration

Let’s explore the main challenges warehouse operators and WMS providers face in implementing a Warehouse Management System and discuss methods to overcome these challenges.

Data integrity and accuracy issues

During the data synchronization process, problems and misunderstandings may arise if the data formats used in the WMS (Warehouse Management System) are incompatible with those used in other linked systems. Besides, manually entering or having the same data in several systems might create inconsistencies and need clarification for inventory numbers, order statuses, and other essential information.

Compatibility challenges with existing systems

Integrating a modern Warehouse Management System (WMS) with older legacy systems can be challenging due to the disparity in technological standards, necessitating a solution that effectively merges all tools available. Additionally, WMS should guarantee a high scalability level as a business expands. Issues can surface if the current integration setup needs help managing growing data quantities or the complexity of processes.

Training and adoption hurdles for employees

Companies need to conduct training for warehouse staff and other users of the new integrated system to avoid causing reluctance to use the system, leading to mistakes and not fully utilizing its features. Besides, employees who are used to old ways might push back against the changes brought by WMS cloud integration, making it essential to have solid strategies for managing this resistance to change.

Strategies to overcome integration challenges

- Data Mapping and Transformation. Implement robust data mapping and transformation processes to ensure seamless data flow between systems with different data structures. What is a WMS system? It is a tool that helps prevent data integrity issues.

- Flexible Integration Solutions. Choose integration solutions that offer flexibility and adaptability, especially when dealing with a mix of modern and legacy systems. It ensures compatibility and smoother integration processes.

- Continuous Training and Support. Provide ongoing training and support to employees to enhance their understanding of the integrated system. Addressing their concerns and ensuring a smooth transition is crucial for successful adoption.

- Regular System Audits. Conduct regular audits of warehouse management systems to identify and rectify any emerging issues. This proactive approach helps maintain data accuracy and prevents potential disruptions in warehouse operations.

These challenges are considered the most critical, requiring a multifaceted approach. What is a WMS system? It is a tool that helps overcome difficulties and ensure a seamless and efficient integration process, leading to a more cohesive and productive warehouse operation.

Future of Warehouse Management

Warehouse management is poised for an exciting future, with technological progress transforming the supply chain domain. Various emerging trends and developments will influence the direction and evolution of Warehouse Management cloud systems and methodologies. Let’s learn what the place of WMS is in the future:

Advanced Automation

Anticipated robotics and autonomous systems advancements will significantly transform warehouse activities. Automated guided vehicles (AGVs), robotic arms, and drones will become more prevalent in product selection, packaging, and handling materials (especially for the last-mile delivery model).

Artificial Intelligence (AI) and Machine Learning (ML)

Implementing AI and ML is expected to improve decision-making in a Warehouse Management System (WMS) significantly. Advanced predictive analytics and intelligent algorithms are poised to refine inventory control, demand prediction, and planning of shipping routes, boosting efficiency and reducing costs. The system must have access to real-time data from various sources within the warehouse, such as sensors, barcode scanners, and RFID systems.

Internet of Things (IoT) Integration

IoT technology will connect various devices and sensors across warehouses, allowing immediate stock, equipment, and workforce monitoring. This network of connected devices will enhance visibility, tracking, and overall operational reactivity. What is WMS system software? This tool is a perfect solution for smooth operational activities.

Blockchain for Supply Chain Transparency

There’s an expectation for increased use of blockchain technology to ensure transparency, tracking, and security within supply chains. It will be especially crucial in sectors with strict regulatory demands and a focus on product genuineness.

Edge Computing for Real-Time Processing

Edge computing will become more prominent for immediate data processing in warehouses. This method minimizes delay and accelerates data analysis, facilitating quicker and more effective decision-making. It is another reason for companies to integrate a WMS warehouse management system.

Integrating WMS with IntelliSoft

What is WMS? It’s a life preserver for businesses. If you want to guarantee seamless and successful WMS implementation, wouldn’t selecting a provider with a proven track record be wise?

At IntelliSoft, we expect every customer to benefit fully from warehouse management systems. That’s why we offer an easy-to-follow yet thorough implementation process, ensuring you get it right from the start. Besides, we provide rigorous user training to support your adoption efforts.

After implementation, we continue to support your system with regular updates and maintenance. This approach keeps your system running smoothly and avoids unexpected expenses.

Contact us today to start your journey with a reliable and supportive WMS provider.