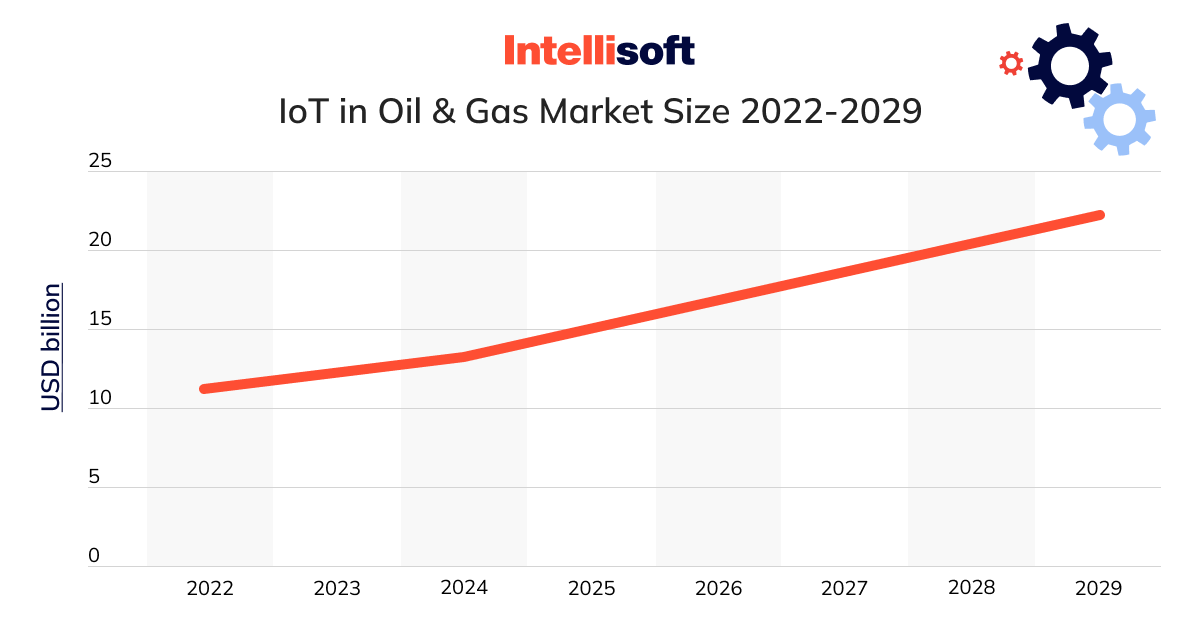

The way we use tech in the energy world is changing big time, especially with IoT for the oil and gas industry. There’s a big jump in this market – it’s expected to double from $11.34 billion in 2022 to a whopping $22.24 billion by 2029. This jump shows just how crucial IoT has become. It’s helping oil and gas companies keep an eye on and manage their big, spread-out operations.

IntelliSoft is right in the middle of all this IoT buzz. Take our project with a European company that makes industrial equipment as an example. We used IoT to make things run smoother and added smart devices to help control and watch over heating systems from afar. Our experience in this area shows just how much IoT can influence change in the oil and gas world. It’s not just about working more efficiently – it’s also about being safer and kinder to the environment.

Let’s uncover the transformative impact of IoT for oil and gas industry and why companies are racing to embrace these solutions. Let’s learn how IoT is reshaping the industry and fueling its future growth, with an expected Internet of Things in energy market size of $35.2 billion by 2025.

Table of Contents

IoT in Oil and Gas Market Highlights

The oil and gas industry, long known for its complex operations and substantial economic footprint, is experiencing a substantial transformation thanks to the advent of the Internet of Things (IoT). With the latest reports from Acumen Research and Consulting and Industry Research, the narrative is clear: Internet of Things, which was once perceived as an addition to this sector, is becoming its backbone. Let’s discuss the growing role of IoT in oil and gas and explore how this technology is reshaping the industry landscape.

The Surge of IoT in Oil and Gas

Recent market analysis paints an impressive picture of IoT’s growing role in the oil and gas industry. According to Acumen Research and Consulting, the IoT in oil and gas market is expected to soar to USD 27.7 billion by 2032, increasing at a CAGR of 9.7% from 2023 to 2032. This growth trajectory underscores the escalating adoption of Internet of Things technologies – from sophisticated sensors to advanced connected devices – across the industry.

Why this surge, you might ask? The answer lies in the deep impact of IoT on operational efficiency, cost reduction, and, most crucially, safety. Technologies such as predictive maintenance, fueled by Internet of Things, became game-changers that are turning conventional oil and gas operations on their head. Similarly, smart oil fields, equipped with state-of-the-art sensor technology and communication protocols, are no longer a vision of the future but a present reality.

Regional Highlights: A Global Perspective

The IoT wave in the oil and gas sector is not confined to a single region. While the Asia-Pacific region led the charge in 2022, holding more than 38% of the market share, other areas are not far behind. The Middle East and Africa, regions with vast oil and gas reserves, are expected to record a CAGR of more than 10.1% from 2023 to 2032. This regional growth is a testament to the availability of resources and the increasing embrace of technology to optimize these resources.

In terms of market segmentation, the upstream segment (involving exploration and production) captured the largest share in 2022. This trend shows a growing recognition of the importance of implementing Internet of Things in the initial stages of oil and gas operations. By application, the fleet and asset management sector is anticipated to grow at the quickest annual growth rate between 2023 and 2032, highlighting the industry’s focus on improving efficiency and asset utilization.

Driving Factors: Efficiency and Cost Reduction

So, what’s propelling this remarkable growth? The primary drivers are the ever-present industry needs: operational efficiency and cost reduction. In an industry characterized by large-scale operations and significant investments, optimizing processes and minimizing expenses are imperative objectives. Internet of Things provides a viable and effective pathway to achieve these goals.

The integration of IoT oil and gas operations offers real-time monitoring and data analysis, enabling quicker and more informed decision-making. This shift enhances operational efficiency and significantly reduces costs associated with downtime and maintenance. Besides, IoT-driven predictive maintenance can foresee potential equipment failures, preventing costly repairs and extending the lifespan of expensive machinery.

Technological Advancements: A Closer Look

The technological landscape of IoT in oil and gas is diverse and evolving. Sensing technologies provide critical data about various operational parameters, while communication technologies ensure seamless data transfer. Cloud computing and data management capabilities are central to handling and analyzing the massive volumes of data generated by IoT devices. These technologies collectively form the foundation of an interconnected and intelligent oil and gas operation.

Prominent players such as Cisco Systems, IBM, Intel, ABB Ltd., and Microsoft Corporation are at the forefront of driving these technological advancements. Their contributions range from developing robust Internet of Things platforms to providing specialized services that cater to the specific demands of the oil and gas sector.

Market Analysis and Future Outlook

The oil and gas market is seeing significant changes thanks to IoT, driven by new developments in sensor tech and data analysis. But, it’s not all smooth sailing. There are hurdles such as keeping data safe and the high costs of setting things up. Yet, there’s a bright side. There’s room to grow by using IoT applications in oil and gas industry and combining it with AI and machine learning for even smarter data insights. The Asia-Pacific region is stepping up in this area, investing heavily in IoT and backed by supportive government policies.

As we can see, the IoT in oil and gas market is on an upward trajectory, driven by the need for enhanced operational efficiency and cost reduction. With significant growth projected in various regions and across multiple segments, the industry is poised to undergo a transformational change. As Internet of Things technologies continue to evolve and integrate more deeply into the oil and gas sector, the possibilities for innovation and improvement seem limitless.

The Role of IoT for Oil and Gas Sector

In the fiercely competitive realm of the oil and gas industry, staying ahead means embracing the latest technological advancements. The Internet of Things (IoT) has emerged as a pivotal force, reshaping the industry from the ground up. In this sector, IoT is more than just a network of physical objects – it’s a comprehensive system of remote sensors, machine learning, and cloud technology deployed across upstream, midstream, and downstream operations.

The intricate network built around Internet of Things devices streamlines data collection and processing while allowing you to leverage this data for more efficient, rapid, and effective decision-making. The result? A noticeable boost in productivity and optimization, with a sharp focus on equipment monitoring using real-time data and a significant increase in safety and security during the extraction and delivery of resources.

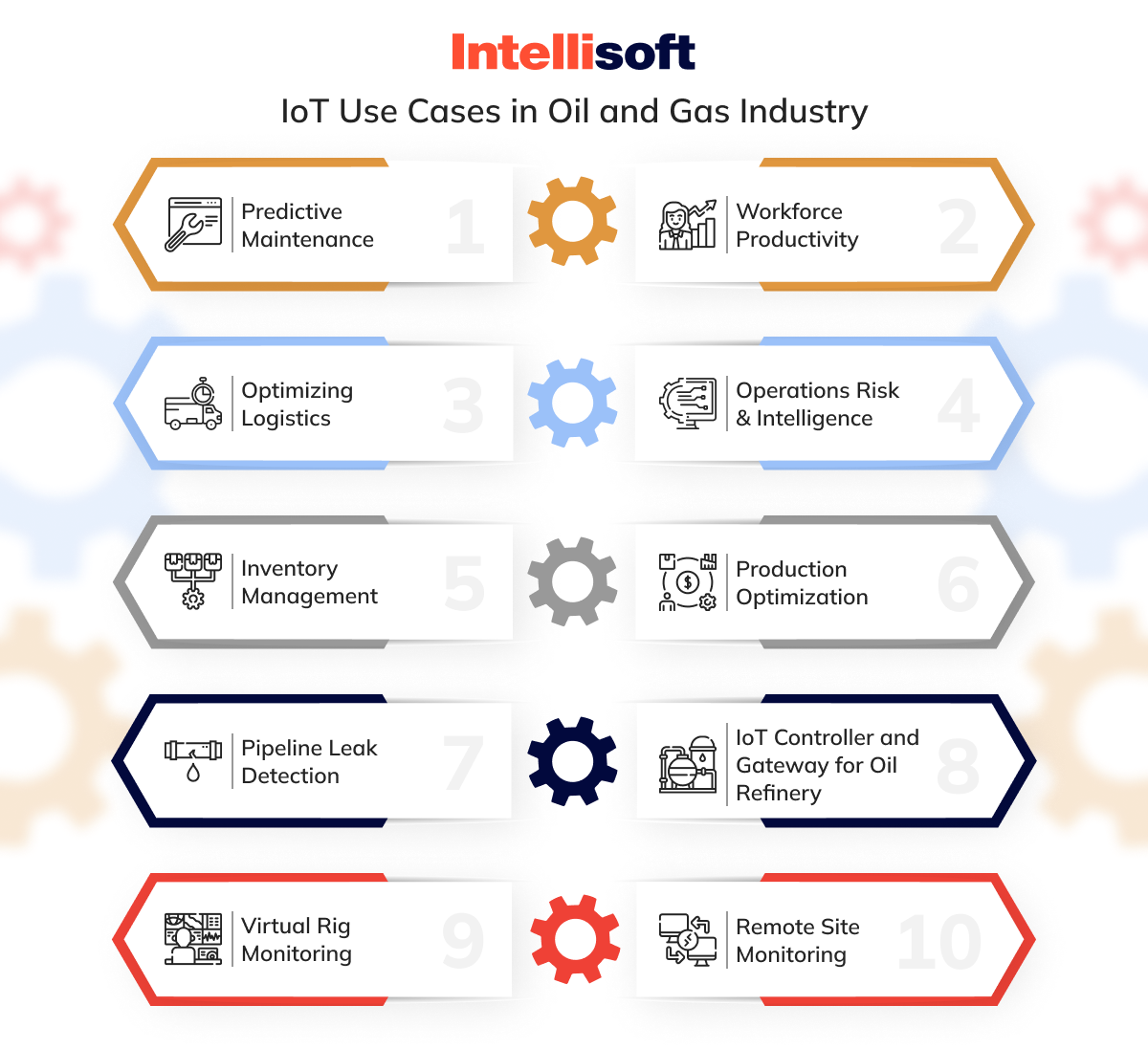

Transformative IoT Use Cases in Oil and Gas

Now, let’s talk about the most popular of the countless ways industry leaders use IoT technologies to push the limits of efficiency and safety.

Predictive Maintenance

The integration of IoT in oil and gas industry has revolutionized the way we approach predictive maintenance. By attaching Internet of Things devices to machinery, companies can anticipate maintenance needs and schedule repairs well before breakdowns occur. This proactive strategy prevents lengthy downtimes and ensures employee safety. IoT-driven predictive maintenance reduces operation costs while enhancing equipment longevity through smart machine-learning algorithms and sensor data analysis.

Enhancing Workforce Productivity

IoT bridges communication gaps between field and office workers, improving safety and productivity. The deployment of sensors, drones, and robots facilitates safer data gathering, reducing the need for on-site personnel. Internet of Things and big data collaborate to optimize energy management and equipment usage, enabling oilfield workers to stay connected and more efficient.

Streamlining Logistics and Supply Chain

IoT plays a crucial role in revolutionizing end-to-end logistics in the oil and gas industry. Enhanced connectivity leads to improved demand management, material tracking, and logistics operations. With IoT, materials, and equipment can be proactively managed and tracked, reducing costs and improving efficiency in hazardous and hard-to-monitor exploration sites.

Mitigating Operations Risk and Intelligence

IoT gadgets are a game changer in drilling, a big part of the costs in producing oil and gas. These devices, along with advanced analytics, make better use of resources. This method not only increases the output but also cuts down the time needed for operations. Plus, having semi-automated processes in the field lowers the risk for workers and reduces the costs involved in training new staff.

Real-Time Inventory Management

In refineries, IoT sensors play a crucial role. They give essential details about the types of oil being processed. This info is key for making smart choices in manufacturing, keeping track of inventory, and overall operational planning. IoT, together with connectivity tools, makes inventory management more efficient in real time. This information leads to better tracking, less waste, and a smoother supply chain.

Production Optimization through IoT

IoT empowers companies to control production processes remotely, reducing the need for physical labor. As Internet of Things devices feed more data into algorithms, production efficiency improves, minimizing the risk of human error and enhancing throughput while reducing energy consumption and emissions.

Advanced Pipeline Leak Detection

Monitoring pipeline health is another critical area where IoT shines, especially in spotting leaks early. The sensors keep an eye on various factors, alerting to possible leaks. Early detection is crucial. It helps to prevent harm to the environment and avoids loss of production. IoT in this context is not just a technological tool – it’s a guardian of both efficiency and environmental safety.

IoT Controllers in Refineries

Refineries utilize Internet of Things controllers and gateways to collect data from assets and equipment. This data, ranging from oil level measurements to energy consumption, aids in tracking performance and identifying discrepancies in the refining process.

Virtual Rig Monitoring

The dawn of Low Power Wide Area Networks (LPWAN) has revolutionized rig monitoring. LPWAN satellite hybrid architecture offers a cost-effective solution for active rig management, providing essential data for reliable integrity calculations.

Remote Site Monitoring

IoT enables remote monitoring of upstream oil and gas production, allowing maintenance teams to be more proactive and enhancing worker safety by reducing exposure to hazardous environments.

IoT Innovations in the Oil and Gas Sector

The applications of IoT in oil and gas industry extend to areas like real-time shipment tracking, mobile field enablement, pipeline health monitoring, refinery automation, and tank monitoring. Each of these applications demonstrates the versatility and breadth of IoT’s impact on the industry.

One of the most forward-thinking applications is the use of digital twins. This technology offers virtual simulations of assets to optimize value and improve maintenance operations. In seismic oil exploration, Internet of Things sensors connected via fiber optic cables map drilling sites, enhancing site selection and rig productivity.

Furthermore, IoT plays a crucial role in carbon emission control and hazard management. By improving plant efficiency, Internet of Things solutions contribute to environmental protection. In terms of worker safety, IoT reduces the need for human presence in dangerous conditions, enhancing overall safety and emergency responsiveness.

The transformative potential of IoT in oil and gas industry is vast and versatile. The use of IoT technologies is reshaping the way the industry operates, offering more efficient, safe, and sustainable solutions.

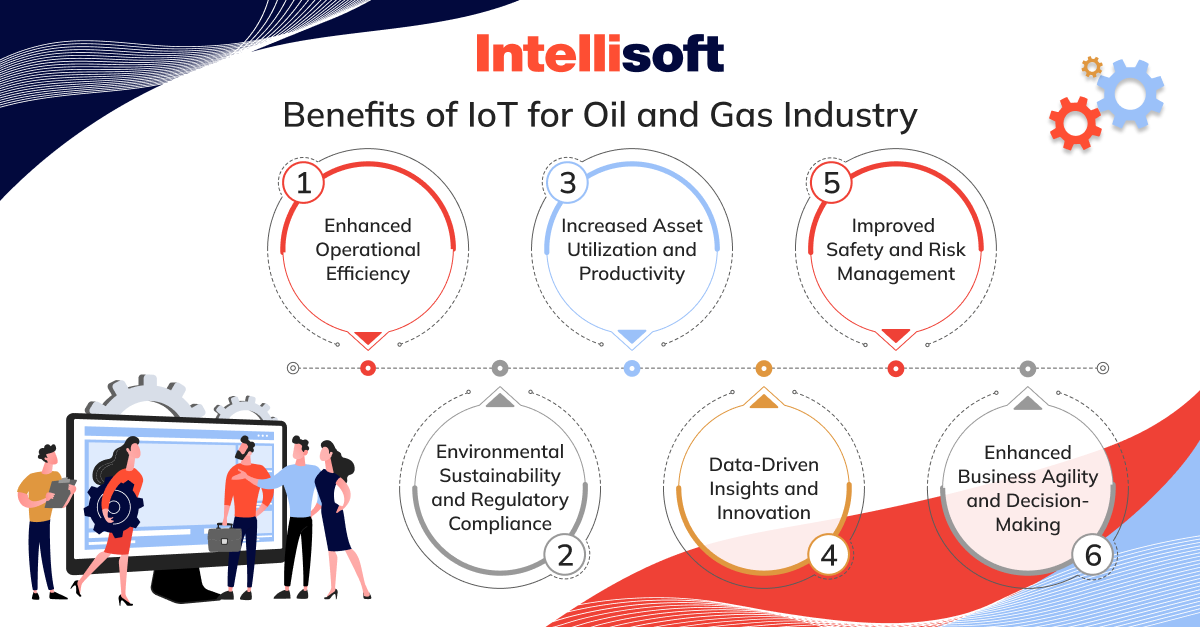

The Benefits of Leveraging IoT in the Oil and Gas Sector

The oil and gas industry is being transformed by the Internet of Things (IoT). This tech is changing how the sector works. In today’s world, where doing things efficiently, sustainably, and safely is crucial, IoT is key. Let’s look at how IoT is making a big difference in the oil and gas world.

Boosting Operational Efficiency

A major benefit of IoT for oil and gas is how it ramps up operational efficiency. IoT systems have top-notch sensors that gather precise info from different assets and send it straight to dashboards for users to see instantly. This fast flow of data helps in making smart resource decisions and spotting trends. This approach leads to smoother operations and cuts down on maintenance costs.

The ability to operate in a consistently cost-effective environment while minimizing environmental impact is a testament to the effectiveness of Internet of Things in enhancing operational efficiency.

Optimizing Inventory Management

IoT technology revolutionizes inventory management in the oil and gas sector by providing more accurate, real-time tracking of oil stocks. Managers can set priorities and thresholds for their inventories, receiving instant notifications when action is needed. This level of control, even during ongoing processes, highlights the remarkable capacity of IoT solutions to automate and optimize industrial operations.

Streamlining Stockroom Management

The deployment of sensors and IoT devices in industrial operations allows companies to gather insightful data, enhancing their understanding of how to maximize business and operational benefits. With machines increasingly equipped with sensors, data analysis becomes more sophisticated, enabling oil and gas companies to reduce capital costs significantly. This efficient data collection and analysis lead to more reliable and efficient operations, creating new value and opportunities for positive changes in the industry.

ROI and Revenue Enhancement

Investments in IoT technology in the oil and gas sector have yielded fruitful results in terms of enhanced outputs and productivity. For example, in shale gas extraction, IoT-enabled seismic surveillance data allow operators to adjust drilling and fracking processes for better efficiency. Sensors installed in drilling rigs provide a continuous stream of data, informing operators about rig performance. This expansion of Internet of Things technology in the oil and gas industry is directly linked to increased return on investment (ROI) and revenue.

Real-Time Monitoring for Better Decision-Making

Offshore oil and gas production, known for its complexity and risk, benefits significantly from IoT’s real-time monitoring capabilities. IoT devices and smart connectivity enable managers to have an up-to-date and accurate picture of ongoing production, reducing the risk of asset failure and costly downtime. This heightened monitoring capacity is crucial in preventing environmental damage and ensuring worker safety, thus maintaining the company’s credibility.

Eliminating Manual Measurement Errors

IoT automates processes, significantly reducing the need for manual labor and the associated risk of errors. Automated and semi-automatic machines take over tasks such as drilling, inspection, and maintenance in high-risk environments. These machines control and share data with control centers, often managed remotely, thus enhancing efficiency and reducing error margins.

Reducing Safety Risks

Just like in any other sector, in the oil and gas industry, worker safety is always a priority. IoT’s sensing technologies play a vital role in enhancing worker safety. The inclusion of IoT-based tools and solutions enables more effective operations and remote monitoring in disaster-prone areas. Early detection of potential challenges helps mitigate risks, aiming to enhance worker safety and reduce the likelihood of critical health-affecting incidents.

IoT is a cornerstone technology in the oil and gas industry, bringing a multitude of benefits. This technological evolution is reshaping the way the oil and gas sector operates, paving the way for a more efficient, sustainable, and safe future.

IoT in Oil and Gas: Key Segment-Specific Usages

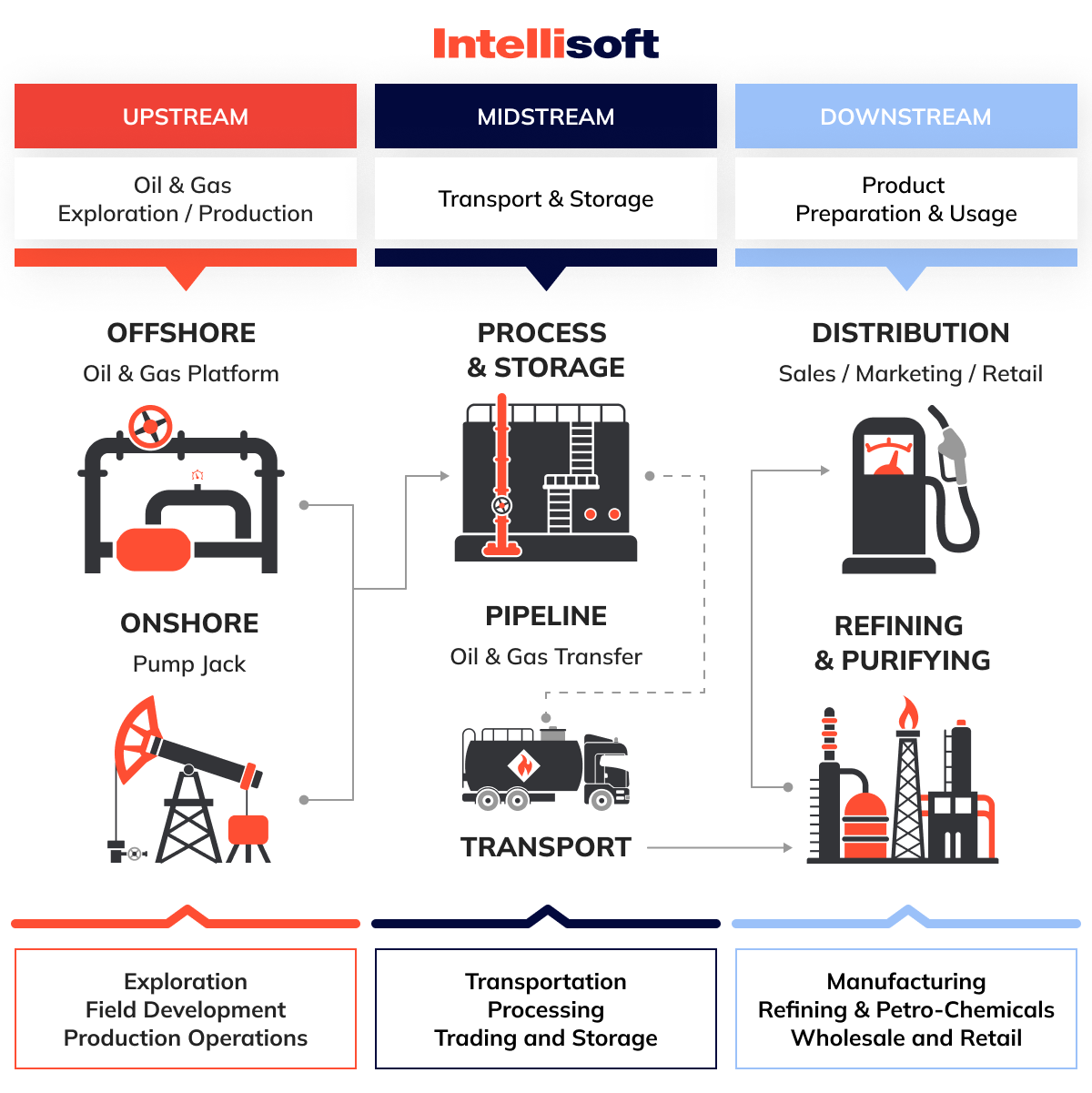

The oil and gas industry, a titan in the energy market, operates through three distinct segments: upstream, midstream, and downstream. Each segment of the supply chain plays an important role in securing the effectiveness of the overall process. Upstream focuses on extracting oil and natural gas, midstream handles the transportation and storage, and downstream deals with refining and distributing fuel oils and finished petroleum products. This industry noted for its extensive capital investments and complex processes, is pivotal in making natural resources accessible for various essential applications.

Upstream: Harnessing IoT for Exploration and Production

The upstream sector, which involves the exploration, drilling, and production of oil and gas, has seen a transformative impact due to the advent of the Internet of Things (IoT). Here’s a closer look at the key IoT use cases revolutionizing the upstream segment:

Asset Monitoring

IoT sensors and devices are deployed for real-time monitoring of equipment and assets. This continuous surveillance provides critical data on the condition, performance, and health of these assets. Such insights are invaluable for predictive maintenance, which helps reduce downtime and avert expensive equipment failures.

Remote Monitoring

One of the standout features of IoT in upstream operations is its ability to enable remote monitoring. This ability is particularly significant for remote and offshore drilling operations, where operators can now control equipment and access data from centralized locations. It allows operators to improve safety and minimize the need for on-site personnel.

Environmental Monitoring

In an industry under close scrutiny for its environmental impact, IoT sensors play a crucial role in monitoring environmental factors. This real-time monitoring aids in compliance with stringent environmental regulations and helps in the proactive management of potential spills or leaks.

Drilling Optimization

IoT sensors affixed to drilling equipment provide essential data on various drilling parameters. This information allows for real-time adjustments, resulting in more efficient and precise drilling operations. The outcome is a dual benefit of cost savings and accelerated well development.

Reservoir Management

IoT technology significantly enhances reservoir management. By collecting data on reservoir conditions, Internet of Things aids in reservoir modeling and optimizes production strategies. This approach ensures maximum recovery from each reservoir.

Safety and Security

Ensuring the safety of the workforce on oil rigs and well sites is crucial. It’s a high-risk job that requires utmost attention and care. IoT-based safety systems are capable of detecting hazardous conditions, ensuring a safer working environment. Additionally, Internet of Things security solutions are critical in protecting vital infrastructure from cyber threats.

Supply Chain Optimization

The movement of materials and equipment is a logistic challenge in the upstream segment. IoT helps track and manage these movements, ensuring timely deliveries and cost reduction across the supply chain.

Data Analytics

Finally, the vast amount of data generated by IoT devices offers a goldmine of insights. Analyzing this data helps make informed decisions and enables process improvements, driving efficiency and innovation in drilling and production operations.

The integration of IoT in the upstream sector of the oil and gas industry marks a pivotal shift towards more efficient, safe, and environmentally responsible operations. It exemplifies how advanced technology can be harnessed to meet the complex demands of this vital industry sector.

Midstream: Streamlining Operations with IoT

In the midstream sector of the oil and gas industry, IoT plays a vital role in enhancing operational efficiency and safety by monitoring the shipping and storage of crude oil, natural gas, and refined products. Let’s explore the key Internet of Things applications that are reshaping this crucial segment.

Pipeline Monitoring

Utilizing IoT sensors along pipelines has revolutionized monitoring practices. These sensors continuously track pressure, temperature, and flow rates, offering real-time data. This capability is crucial for leak detection, optimizing pipeline performance, and preventing potential accidents or environmental hazards.

Tank Farm Management

IoT-enabled systems in tank farms offer an efficient way to monitor storage tanks. They track levels, temperatures, and other critical parameters, thereby aiding in inventory management. This technology simplifies storage management by automating inspections and preventing shortages or overflows.

Asset Tracking

The ability to track equipment and assets in real-time is a significant advantage brought about by IoT. This tracking is essential for managing valuable assets like pumps and compressors, ensuring optimal utilization and maintenance.

Predictive Maintenance

IoT sensors gather critical data from various machinery and equipment in midstream operations. By analyzing this data, companies can anticipate maintenance needs, thereby reducing unplanned downtime and avoiding costly equipment breakdowns.

Safety and Compliance

Safety is a top priority in the midstream sector, and IoT systems contribute significantly to this aspect. They monitor environmental conditions, detect gas leaks, and ensure compliance with safety regulations. In emergencies, Internet of Things systems can send immediate alerts to operators, enabling rapid response.

Energy Efficiency

In an industry where energy consumption is substantial, IoT offers solutions to optimize energy use. Monitoring energy usage and implementing control systems through Internet of Things reduces costs and minimizes the environmental footprint of midstream operations.

Remote Monitoring and Control

The technology of the Internet of Things (IoT) enables the remote monitoring and control of crucial infrastructure. This feature diminishes the necessity for on-site personnel, thus improving operational efficiency. Operators can manage facilities and respond to issues from centralized locations, enhancing responsiveness and oversight.

Supply Chain Optimization

The movement of materials and products is seamlessly tracked using IoT, ensuring efficient logistics management and timely deliveries. This optimization is crucial for maintaining the integrity of the supply chain in midstream operations.

The incorporation of IoT in the midstream sector is evidence of how digital technology can revolutionize traditional industries. IoT technology paves the way for a more streamlined, responsible, and cost-effective oil and gas midstream sector.

Downstream: IoT-Driven Innovations

The downstream segment of the oil and gas industry, encompassing refining, processing, and distributing petroleum products, significantly benefits from the advancements brought by the Internet of Things (IoT). Let’s explore different applications of IoT for downstream oil and gas operations that are enhancing the efficiency, safety, and productivity.

Refinery Optimization

In refineries, IoT sensors play a crucial role in monitoring equipment health and operational parameters. This data is instrumental in optimizing processes, reducing downtime, and thus improving the overall efficiency of refining operations. The ability to have real-time insights into the functioning of equipment ensures more streamlined and cost-effective processes.

Energy Management

IoT’s real-time monitoring capabilities extend to energy consumption within downstream facilities. By analyzing data from these sensors, you can identify areas for energy savings and implement sustainability initiatives. The use of Internet of Things reduces operational costs and contributes to environmental conservation.

Safety and Compliance

Maintaining safety standards and regulatory compliance is a top priority in the downstream sector. IoT systems enhance safety by monitoring environmental conditions, detecting gas leaks, and ensuring regulatory compliance, particularly in refineries and petrochemical plants. In emergencies, Internet of Things systems provide real-time alerts, enabling prompt and effective responses.

Tank Farm Management

IoT-based tank monitoring systems efficiently track levels, temperatures, and other vital parameters in storage tanks. This approach ensures effective inventory management and helps prevent issues such as overflows or shortages in downstream facilities.

Supply Chain Optimization

Internet of Things technology is extensively used to track the movement of products across the downstream supply chain. Using IoT ensures timely deliveries and efficient logistics management, which is crucial for maintaining the flow of products to the market.

Asset Tracking

The location and condition of critical equipment and assets in downstream facilities are continuously monitored through IoT devices. This tracking method helps with maintenance planning, reduces downtime, and ensures the longevity of assets.

Inventory Management

Real-time data on inventory levels and product quality provided by IoT sensors enables downstream companies to optimize stock levels. Using this data, you can control product quality, a critical aspect in the downstream sector.

Predictive Maintenance

IoT technology facilitates predictive maintenance of equipment and machinery in downstream facilities. This approach helps in reducing unplanned downtime and minimizing maintenance costs, thus enhancing the overall efficiency of operations.

Environmental Monitoring

In an era of increasing environmental concerns, you can use IoT devices to continuously monitor emissions and environmental impacts. This technology is essential for ensuring compliance with stringent environmental regulations in downstream operations.

The integration of IoT in the downstream oil and gas industry exemplifies the digital transformation of traditional industrial processes. Internet of Things paves the way for a more efficient, sustainable, and responsive downstream sector.

Related readings:

- IoT Device Security Concepts: IntelliSoft’s Roadmap to Robust IoT Protection

- IoT Connectivity Options: Roadmap to Smart Solutions

- IoT Data Integration with Existing Systems: Bridging the Gap to Legacy Infrastructure

- How To Control IoT Devices To Reach Your Business Goals

- Testing IoT Devices: Why and How to Examine the Internet of Things

IoT in Oil and Gas: Real-World Impact Through Case Studies

The implementation of the Internet of Things (IoT) in the oil and gas industry has led to significant transformations in how companies operate, manage risks, and achieve efficiency. By examining real-world case studies from industry giants like Shell and Euronav, we can gain insights into the practical applications and benefits of IoT in this sector.

Shell’s Digital Oilfield: Revolutionizing Operations

Shell, a global energy leader, has embraced IoT oil and gas operations to significantly enhance efficiency, safety, and productivity. The Digital Oilfield initiative by Shell is a testament to how IoT can be effectively utilized throughout the oilfield lifecycle, encompassing exploration, drilling, production, and maintenance.

Remote Monitoring

At the heart of Shell’s Digital Oilfield is the deployment of IoT sensors on drilling rigs, pipelines, and other equipment. These sensors collect real-time data on temperature, pressure, and flow rates, among other factors. This data is then transmitted to central control centers for remote monitoring, enabling prompt responses to any operational changes or anomalies.

Predictive Maintenance

Utilizing IoT data for predictive maintenance has been a game-changer for Shell. By anticipating equipment failures and scheduling maintenance activities before breakdowns occur, the company has significantly reduced downtime and bolstered operational efficiency.

Safety Enhancements

IoT sensors in Shell’s operations are critical for monitoring safety hazards. They can detect gas leaks or equipment malfunctions and trigger alarms or automatic shut-off systems in emergencies, thereby enhancing overall safety.

Energy Efficiency

Optimizing energy consumption is another area where Shell’s IoT implementation shines. Remote monitoring and control of equipment have led to a reduction in energy waste and operational costs.

Leveraging Data Analytics

Advanced analytics are used to analyze the vast amount of data generated by IoT sensors. This analysis provides deeper insights into oilfield operations, supporting improved decision-making and operational strategies.

Euronav’s Fleet Automatic Statistics & Tracking (FAST): Maritime IoT Applications

Euronav, a significant player in the global shipping industry, demonstrates the application of IoT in the maritime sector, which is crucial for transporting oil and gas products. The FAST system is designed to enhance the management and performance of Euronav’s fleet of crude oil tankers.

Fleet Monitoring

IoT sensors and devices installed on Euronav’s tanker vessels collect real-time data on engine performance, fuel consumption, weather conditions, and vessel location. This comprehensive monitoring ensures efficient fleet management.

Data Transmission

The data gathered is transmitted to onshore data centers via satellite or other communication channels. This approach enables fleet managers to access timely and accurate information about their vessels’ status.

Operational Efficiency

Through the FAST system, Euronav optimizes route planning, fuel consumption, and maintenance schedules. The use of this system reduces operational costs and minimizes the environmental impact of the fleet.

Compliance and Safety Monitoring

IoT technology allows Euronav to adhere to environmental regulations and safety standards. Taking a proactive approach can help to minimize the risk of accidents and environmental incidents.

Decision Support

Data analytics and visualization tools provide actionable insights to fleet managers. This technology promotes informed decision-making and enhances the overall performance and efficiency of the fleet.

These case studies illustrate the transformative role of Internet of Things in the oil and gas industry. By leveraging IoT technologies, companies like Shell and Euronav streamline their operations, enhance safety, reduce environmental impact, and make data-driven decisions. As the industry continues to evolve, IoT stands as a key driver in reshaping its future. These cases demonstrate the vast potential of digital technology in traditional sectors.

Navigating the Challenges of Implementing IoT in the Oil and Gas Industry

While the Internet of Things (IoT) offers transformative benefits to the oil and gas industry, its implementation is not without challenges. These hurdles range from data security concerns to the integration of legacy systems, each requiring careful consideration and strategic planning to overcome.

Data Security and Privacy Concerns

One of the foremost challenges in implementing IoT technologies is ensuring the security and privacy of data. Internet of Things systems collect, transmit, and store large amounts of sensitive information, which makes them potential targets for cyber threats. To safeguard this valuable data and maintain compliance with industry regulations, it’s essential that you implement robust cybersecurity measures.

You need to secure the IoT devices themselves as well as the networks they operate on and the databases where data is stored. Addressing these vulnerabilities requires a comprehensive approach, incorporating advanced encryption methods, regular security audits, and continuous monitoring for potential threats.

Integration with Existing Systems

Many oil and gas companies operate on legacy systems and equipment, which poses a significant challenge when integrating new IoT solutions. These legacy systems often lack the compatibility or flexibility needed to seamlessly incorporate modern IoT technologies.

Overcoming this hurdle requires a thorough understanding of the existing infrastructure and a well-planned implementation strategy. This approach might involve gradual integration, where IoT solutions are slowly phased into the existing setup, or a more comprehensive overhaul if the legacy systems are too outdated to support IoT integration effectively.

High Initial Investment Costs

The deployment of IoT solutions in the oil and gas industry often entails significant upfront costs. These costs include hardware purchases, software development, and infrastructure upgrades. You must weigh these initial investments against the prospective long-term benefits and return on investment (ROI) that Internet of Things solutions can bring.

This calculation is not straightforward, as, besides financial considerations, it involves factors such as improved safety, efficiency gains, and potential revenue increases from enhanced operations. A clear understanding of the total cost of ownership and the expected value IoT solutions will bring is crucial for justifying these investments.

Talent and Skill Gaps

The rapid growth of the IoT market has led to a high demand for professionals with specialized skills in IoT, cybersecurity, hardware, and user experience design. Finding top-tier IoT professionals who possess this broad range of expertise can be a significant challenge. The talent gap can lead to increased project costs and make it difficult to execute Internet of Things projects successfully.

To manage this problem, you can invest in employee training, partner with an experienced IoT solution provider, or explore collaborations with academic institutions to foster a pipeline of skilled professionals.

While the challenges of implementing IoT in the oil and gas industry are non-trivial, they are not impossible to overcome. With careful planning, strategic investment, and a focus on talent development, you can navigate these obstacles and fully leverage the benefits of IoT technologies. The key to success is understanding your company’s needs and context and developing a tailored approach to address these challenges.

Strengthen Your Oil and Gas Business with IoT Solutions from IntelliSoft

In the dynamic world of the oil and gas industry, adopting Internet of Things (IoT) technology is more than a smart choice – it’s a strategic imperative for those aiming to stay at the forefront. The integration of IoT allows for transforming operations, boosting efficiency, and trimming costs.

That said, navigating the IoT landscape isn’t without its challenges, such as the need for specialized IoT developers and the complexities of system integration. Here’s where IntelliSoft comes into play, emerging as your trusted ally.

IntelliSoft is an accomplished player with a rich experience in various domains, including IoT solutions. Our team, a blend of expertise and insight, excels in guiding large organizations through the intricate process of integrating IoT and IT data, ensuring a smooth transition and effective scaling for digital transformation. Recognizing the uniqueness of each client, we take pride in crafting tailor-made software applications for the oil and gas sector – solutions that meet your needs and even set new benchmarks.

Picture this: your decision-makers, armed with real-time data analytics, identifying improvement opportunities and seizing growth avenues with unmatched speed and precision. The outcome? Enhanced customer satisfaction, increased revenue, reduced downtime, and a streamlined supply chain. This convergence of factors cultivates a business environment that’s not only more efficient and profitable but also resilient.

In a sector where time is of the essence, IntelliSoft’s software solutions are the edge you need to shine. Whether it’s the top-notch IoT solutions you’re after or the expertise of seasoned IoT developers, IntelliSoft is your destination. Step into the future of the oil and gas industry with IntelliSoft’s IoT solutions. Reach out to us, and let’s march on this path of innovation and growth together.