Companies are constantly on the hunt for proven strategies to slash costs and stay ahead of the curve. One area that can’t be overlooked is the optimization of operations, especially through savvy supply chain management. Enter supply chain predictive analytics—a game-changer that allows businesses to mine deep into data, revealing insights that enable smarter, more informed decisions to streamline supply chains. This isn’t just about keeping up—it’s about taking the lead, boosting efficiency, and strengthening the bottom line.

At IntelliSoft, we’ve harnessed the power of predictive analytics in supply chain to revolutionize how we forecast fuel consumption for our clients in the industrial manufacturing sector. Our cutting-edge software doesn’t just predict; it acts, automatically placing fuel orders and generating invoices—all without human intervention.

But what exactly is predictive analytics? How can it transform your supply chain for the better? And what hurdles might you encounter along the way? This article dives into these questions, offering you a clear view of how predictive analytics can become your most powerful ally in business optimization.

Table of Contents

Growth in the Use of Predictive Analytics across the Supply Chain

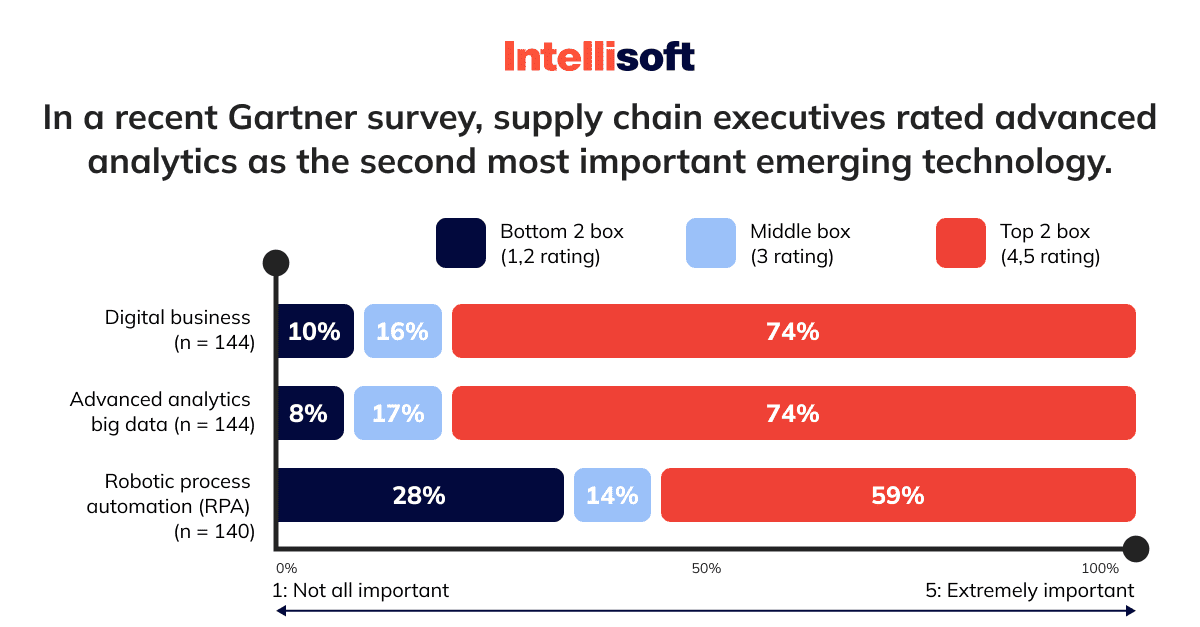

Predictive analytics has become popular among supply chain management:

- The 2022 MHI Annual Industry survey showed that 87% of supply chain businesses say that the pandemic has altered the strategic importance of supply chain operations.

- The survey also says that the leading supply chain challenges are out-of-stock situations for 48% of respondents and forecasting for 46% of respondents.

- Besides this, 27% of supply chain businesses will adopt this technology in the next five years.

The same report also told that the biggest struggles for supply chain managers to adopt predictive analytics are:

- Lack of clear business case to justify the investment (21.0%)

- Lack of adequate talent to implement/utilize technology (17.7%)

- Unwilling to invest due to economic uncertainty (15.9%)

- Lack of understanding of the technology landscape (14.2%)

- Lack of access to capital to make investments (14.1%)

The predictive analytics market reached the value of $12.49 Billion in 2022 and is expected to grow to 20.4% from 2022 to 2028.

Those supply chain businesses that adopt predictive analytics can tweak their business processes and achieve efficiency that wasn’t possible in the past. Why? Because such companies can create predictive insights into the business data and be able to take actions based on future trends rather than historical data.

What Is Predictive Analytics?

What is predictive analytics for supply chain? As you can understand from its name, the primary purpose of predictive analytics is to predict future trends. This function can be applied to sales demand, enhance the rate, and other metrics important in the supply chain. All predictive analytics software leverages the algorithm, including statistical modeling and regression analytics, to historical data. In this way, the software can determine and create trends to formulate trends that will be in the future.

The supply chain predictive analytics technique isn’t new – it has been around since the rise of personal computers. But only after computers became more advanced and powerful enough to analyze large amounts of data has predictive analytics become handy for applying data mining techniques to find insights from structured and unstructured data.

In a nutshell, you can’t predict the future using predictive analytics. It is rather about using probability theory that helps you to determine that some actions are more likely to happen in the future than others. The technology leverages patterns and trends hidden in historical data to achieve such a forecast. Thus, bear in mind that to adopt predictive analytics in supply chain, you’ll need to ensure the availability of data that the algorithm will analyze.

With this in mind, let’s see how exactly predictive analytics algorithms work and what steps they include.

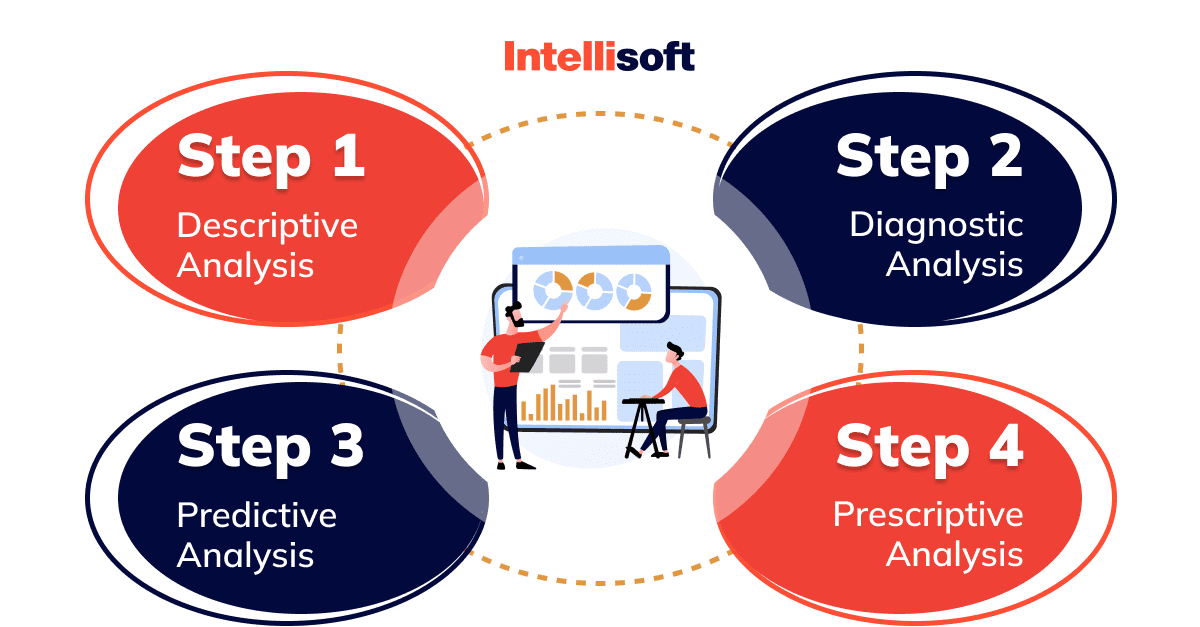

What are the four steps in predictive analytics?

Predictive analytics algorithms include four main steps. They are descriptive, diagnostics, predictive, and prescriptive analysis. Let’s take a closer look at them one by one.

Step 1: Descriptive Analysis

A Descriptive Analysis is a type of reporting that helps organizations to receive answers to the “what was” question. In this way, you can find out the following:

- What was the number of products sold during the last quarter?

- What was the revenue?

- What was the distance that drove the drivers to deliver cargo?

Descriptive reporting is always the best way to find out what is happening. By using such reporting, you can better understand what data you need to leverage along the analytics value chain to dig into more valuable information, and as a result, to the point of action.

Step 2: Diagnostic Analysis

Diagnostic analytics is the next step in the process of data analysis. The main question you are answering in this step is “why?”.

- Why did the number of products you sold in the last quarter decline?

- Why was the revenue 20% higher than in the previous quarter?

- Why do drivers drive 30% of extra miles?

In this step, you need to evolve additional intelligence and data sources to examine cause-and-effect relationships and answer those questions.

Step 3: Predictive Analysis

Supply chain predictive analytics means applying machine learning and AI (artificial intelligence) models trained with your historical data gathered during previous steps. In this way, you can get forecasts on what is likely will happen in the future:

- How many products will customers buy during the next year

- What revenue will your business generate

- What will be the fuel consumption for shipping the same amount of cargo in the next year

Step 4: Prescriptive Analysis

Data analysts consider Prescriptive Analytics the highest level of the analytics value stream. Why? Because this type of analytics helps you to take action when there is a time between reporting and decision-making.

Thus, you think about the results received not only as a source for things that your business is going wrong. You receive a “prescription” and guidance on how to improve your situation.

One example is when you receive a prediction from a prescriptive analysis of your data about an item in high demand. The algorithm will recommend you order those items and suggest the required quantity to ensure you receive them before they are out of stock.

The same scenario applies to products that are not popular among customers. In this case, you receive suggestions to change your supply chain so that your business will end up with less overstocking.

In a nutshell, by applying prescriptive guidance from your data, you’ll be able to bring competitive value to your supply chain business thanks to logical and rapid decision-making.

If you still need clarification about whether your supply chain business needs predictive analytics, read on because next, we’ll overview the benefits you can receive by leveraging this technology.

Why Is Supply Chain Analytics Important?

You’ll make more innovative and effective decisions in the shortest terms by using predictive modeling tools in the supply chain. As for other benefits of supply chain predictive analytics for your business, they are the following:

Reduced costs and improved margins

You receive valuable insights and real-time visibility into what you need to change in your business organization to achieve operational efficiency.

A better understanding of risks

By having data analytics reports and predictions of future events, you’ll be able to identify potential risks and spot patterns throughout the supply chain.

Increased accuracy in planning

After analyzing customer data with predictive analytics algorithms, you can better predict future demand. Thus, plan your business activities according to the forecasts – you’ll know what products you need to minimize in your warehouse since they are less profitable.

Prepared for the future

Applying advanced data analytics technology of structured and unstructured data to your supply chain management gives you an edge in making optimal decisions. Using advanced analytics, you can also build correlations and patterns among different sources to minimize risks at little cost and with less sustainability impact.

Thanks to AI and predictive modeling tools that have become more leveraged in supply chain analytics, businesses receive all the benefits we mentioned.

In the next section, you’ll learn how exactly supply chain predictive modeling tools work and what preparation it requires.

Predictive Analytics Modeling For Supply Chain

Let’s imagine that you decided to integrate supply chain predictive analytics into your business processes. Where should you start?

Your first step will be to hire data analytics experts who will be responsible for all the processes we’ll mention further. Once you team up with the necessary experts, they’ll perform further preparations and actions:

- Create the model. Data analysts will develop a mathematical model representing the trend in your business you need to understand. To achieve this goal, analysts will simultaneously test several forecasting models to determine the one model that describes reality as closely as possible. This stage includes testing the model with your historical data and refining it until it can reliably forecast actions in the past.

- Train the model. During this stage, data analysts will add the current data to the created model so that the model can forecast future trends. It’s essential to define whether the model applies probability theory to predict what’s most likely to happen. Consider that the more high-quality data your model analyzes, the better the forecast.

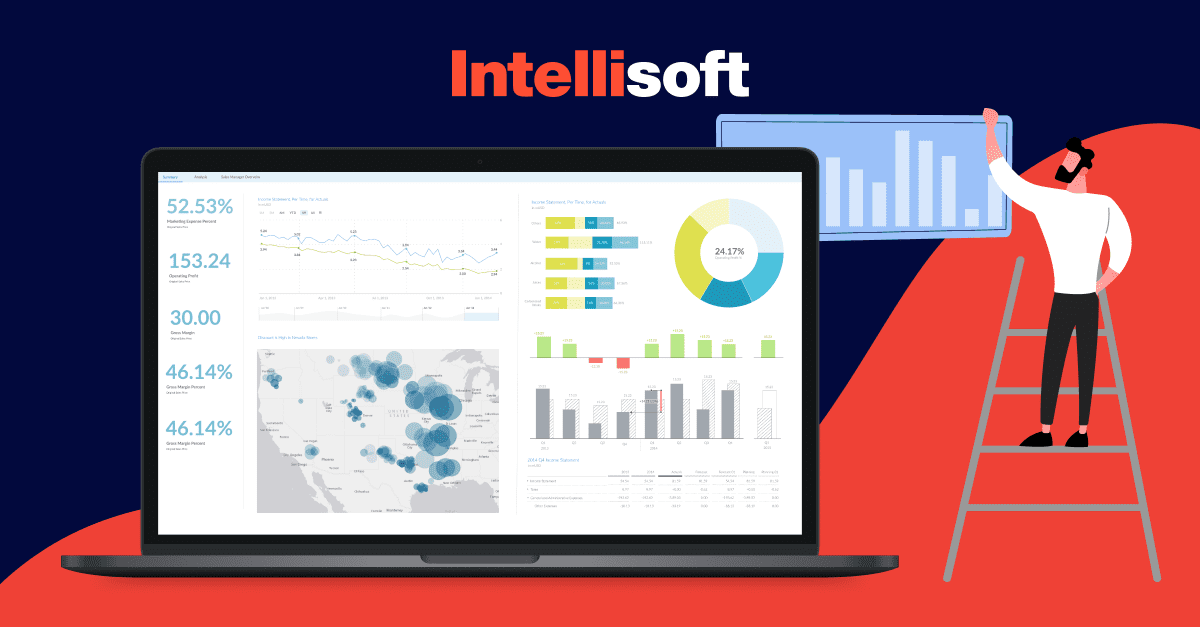

- Visualize results. Data visualization is the final stage of predictive modeling and analysis. Such visualizations will allow you to see the result of data modeling and drill down to get more detailed data. As a rule, the predictions come from spreadsheets with tons of data. To read and understand your predictions, you’ll need a visual dashboard.

With this in mind, let’s find out where you can apply data analytics in the supply chain.

Applying Supply Chain Predictive Analytics: Key Usages

Imagine that you have decided to apply predictive analytics in supply chain. But where should you use this technology? As a supply chain professional, you can leverage this technology in the following spheres – demand forecasting, pricing strategy, inventory management, shipping, and even predictive maintenance.

Below we’ll overview examples of predictive analytics in supply chain we just mentioned one by one.

Demand forecasting

I bet you are looking for a better understanding of your forecasting in supply chain predictive analytics. For many supply chain professionals, demand forecasting remains a critical challenge. Why? Because demand is never linear. Numerous variables, even those outside the organization’s control, affect the market.

Fortunately, you’ll improve your demand forecasting with a predictive analytics platform. How? By analyzing past and current trends, market intelligence, and economic forecasting.

Other elements of demand forecasting and planning include:

- Running statistical analysis of sales, inventory, etc.

- Creating the model that’ll analyze your data to predict future demand.

- Gathering other data from suppliers and manufacturers on events that could affect the market.

Predictive pricing strategies

Pricing strategies are another pain point for all supply chain professionals. The main reason for this is the limitation of historical cost-plus pricing strategies. Thanks to data analytics, you’ll be able to adjust the process dynamically according to the market demand instead of forecasting how demanding your products will be in the future.

The mechanism of predictive pricing strategy looks the following way: data analytics gather past data to identify customer spending patterns and pricing elasticity. Then, analysts combine all these factors to identify the most beneficial pricing strategy, spending on marketing, and other costs that will increase profitability.

Inventory management

Consider integrating predictive analytics if you are looking for a solution to help determine optimal inventory levels. This technology is widely used in the supply chain to optimize inventory while minimizing stock and satisfying demand.

You’ll benefit from predictive analytics in supply chain if your business has multiple distribution points. By leveraging predictive analytics models, you’ll see the inventory level required by sale, location, and region. As a result of intelligent algorithms, you can reduce the stock level where it is unnecessary and place inventory where it is required. How? Because you’ll know whether to hold your stock centrally or distribute it among regional facilities.

Shipping and logistics

You probably know that transportation costs define a significant percentage of the final product price. If you apply predictive analytics to this sphere, you’ll determine the most appropriate shipping quantity and frequency to minimize costs while meeting demand.

One example is a predictive road planning model that will determine the fastest roads while considering the distance, weather, traffic congestion, and the final destination point.

Another example is using predictive maintenance tools to maintain your trucks. Such a model receives data from IoT sensors, helps you monitor fuel consumption, vehicle condition, and tire pressure, and gives recommendations on when you should replace truck parts.

Supply chain predictive maintenance techniques

You can identify what parts of your inventory require service and receive early notifications of possible component failure using predictive equipment monitoring. You can also use this data to order necessary parts beforehand, thus, reducing spare parts inventory and avoiding equipment outages and supply chain downtime.

In a nutshell, predictive maintenance tools help to monitor component conditions and improve maintenance by detecting anomalies in operations and other defects in equipment. This way, you and your team can fix those defects before the component fails.

When you’re ready to apply predictive analytics to your supply chain, leveraging one or several usages described above, the first step is hiring a data analytics team. This way, experts will dig deeper into your business problem and suggest the most appropriate tech solution.

With this in mind, let’s overview the best solutions for predictive analytics for supply chain. But remember that we showcase those technologies as inspiration sources rather than strict recommendations. Why? Because every business is unique and requires different approaches to its problems and the personalized tech stack.

Related readings:

- Implementing Offline Data Synchronization in Logistics Applications

- How To Develop An App For Logistics Business And Make It Successful

- Top 7 Smart Warehouse Technologies for Ultimate Warehouse Optimization

- Barcode Scanning for Ultimate Inventory Digitalization

- Top 10 Data Warehouse Software Tools for Your Business

What is the best predictive analytics tool in the supply chain?

Based on their experience with previous projects, the IntelliSoft experts can suggest the following proved and reliable predictive analytics software. Our top 5 list includes:

SAP Analytics Cloud

SAP Analytics Cloud is a predictive analytics platform leveraging AI, machine learning, and predictive analytics for enterprise planning and business intelligence. The platform helps organizations to make better data-driven decisions with more confidence by combining augmented analytics, business intelligence, and enterprise planning.

The platform automatically reveals hidden patterns, relationships, and outliers in data so that users can improve their workflow with predictive analytics and achieve better planning and collaboration for better business outcomes.

Key features:

- Self-service data modeling and preparation

- Data exploration and visualization

- Augmented analytics

- What-if simulation

Price: $36/month per user.

IBM Watson Studio

IBM Watson Studio is a predictive tool that operates on IBM Cloud Pak for Data. It is considered the learning data analytics platform for enterprises that want to accelerate AI-driven digital transformation. With the help of this platform, users can build, run, and manage Artificial Intelligence models. Thanks to an automated end-to-end AI lifecycle, the platform allows users to simplify experiments and model deployment, explore and prepare data faster, train models, and manage model risks.

Your developers can seamlessly integrate Watson Studio with your current data management services and open-source frameworks so that developers can build a modern information architecture across your organization.

Key features:

- AutoCAD for faster experimentation

- Advanced data refinery

- Open-source notebook support

- Integrated visual tooling

- Model training and development

- Embedded decision optimization

Price: from the free plan to $1.0486/capacity unit-hour.

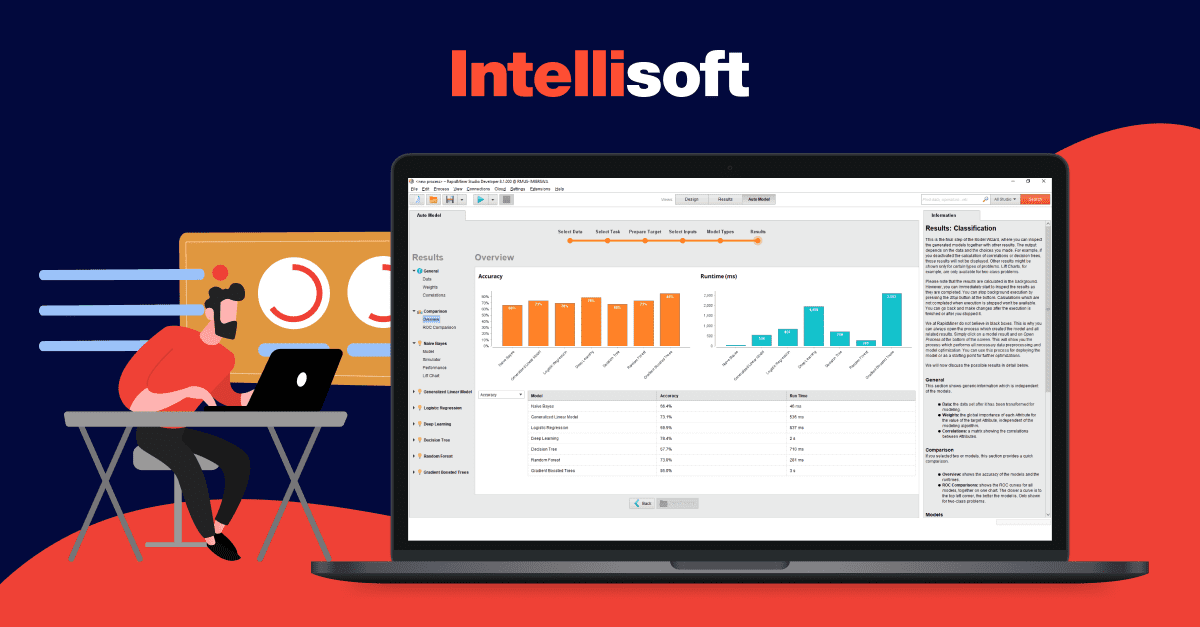

RapidMiner

RapidMiner is a predictive analytics platform for big companies and enterprises. The platform enables users to develop and deploy AI models for data analytics while amplifying the collective impacts of employees, expertise, and business data. This solution has an intuitive interface and includes automation for non-coding supply chain experts. For data scientists, the platform offers integrations with the JupyterLab environment and easy-to-use visual drag-and-drop so that the team remains on the same page.

RapidMiner helps users generate real business impact and maximize profit by making predictive analytics results easy to understand while simplifying Model Ops for more convenient usage.

Key features:

- Clustering

- Data Replacement

- Data Partitioning

- Automation and Process Control

- Data Access and Management

- Data Prep.

- Bayesian Modeling

- Data Exploration

Price: on request.

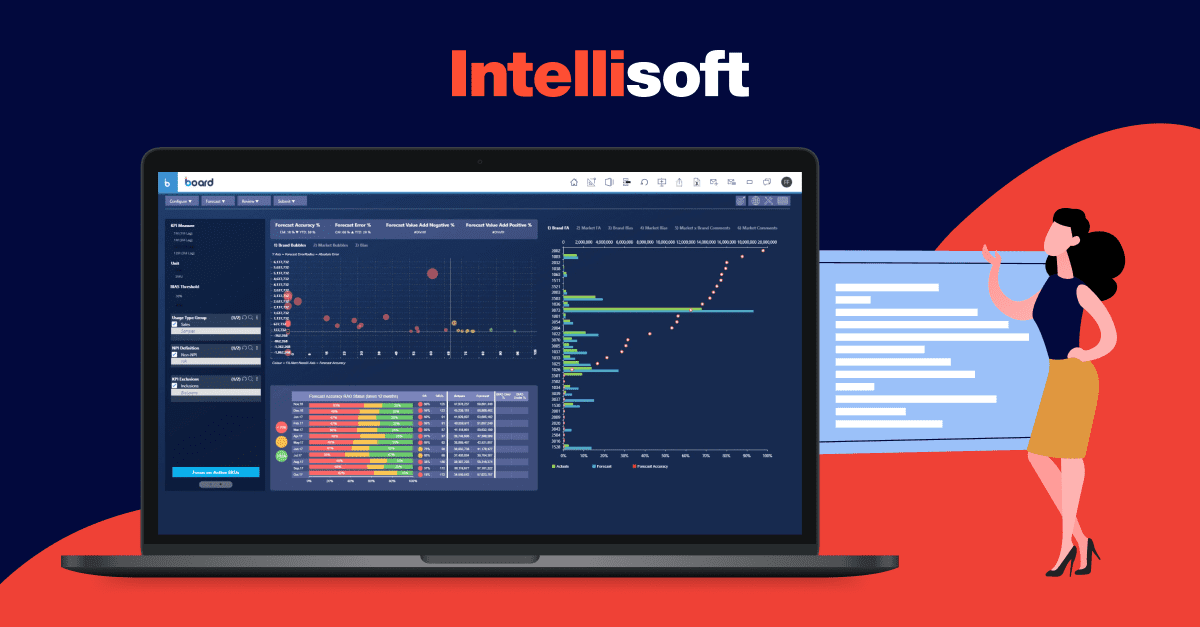

Board

Board is the predictive analytics platform for businesses looking for intelligent planning solutions, better outcomes, and actionable insights. This solution helps users to make better decisions in strategy, finances, and operations and unify them to achieve better results and control over the organization. The platform provides advanced capabilities for predictive analytics supply chain, including machine learning forecasting, simulation, clustering, and statistical functions. Board also has low-code/no-code customization, so even non-technical experts can set up and run the functionality.

Apart from data analytics, the platform is also handy for business intelligence – it allows users to score their activities, track performance via the dashboard, access reporting, and analytics, as well as for performance management. Users can manage budgeting, forecasting, and planning activities, analyze the organization’s profitability, manage the overall strategy, and consolidate finances.

Key features:

- HBMP (Hybrid Bitwise Memory Pattern)

- Drag and drop analysis

- On-the-fly calculated metrics

- Real-time Modeling

- Simulation

- Reverse Algorithm

- Scenarios and Versions

Price: on request.

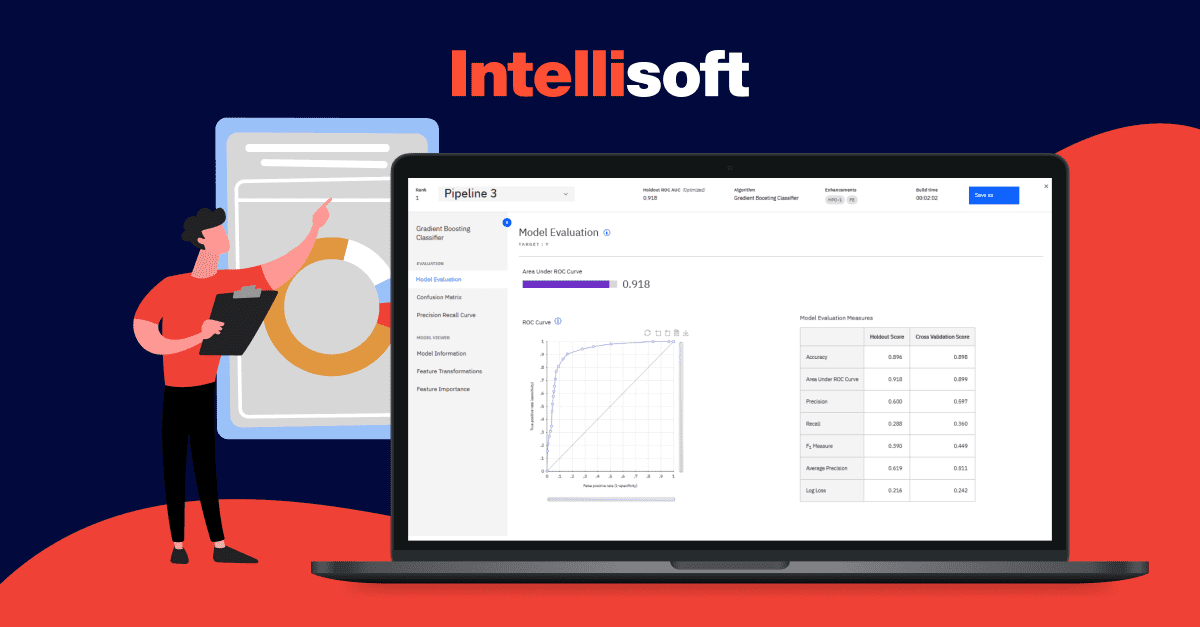

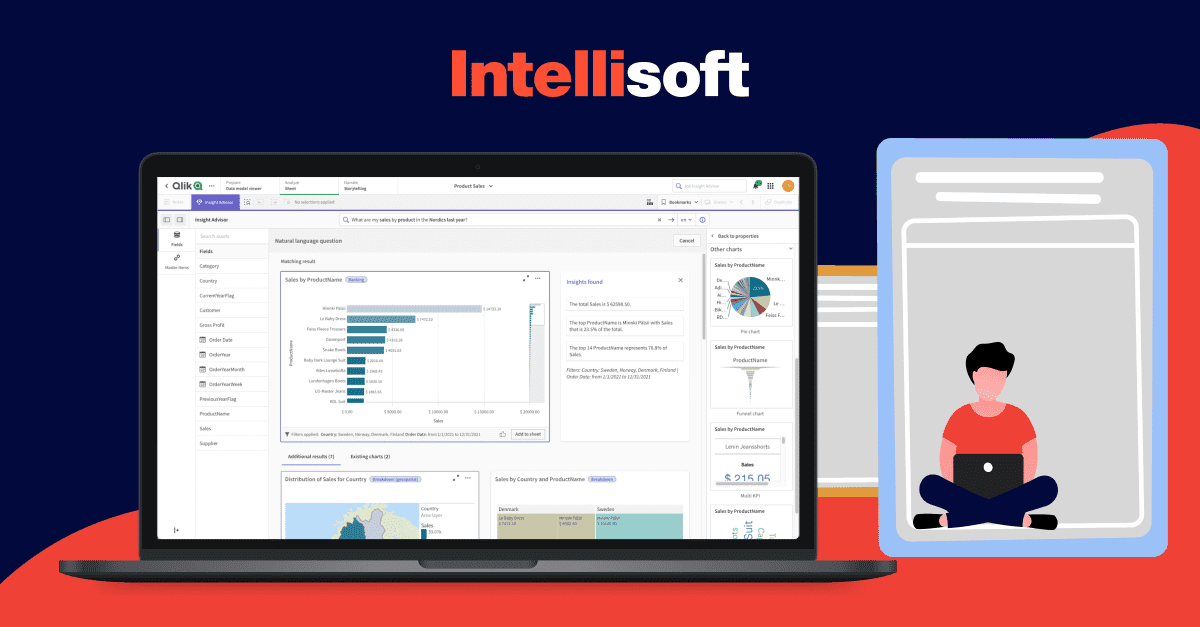

Qlik AutoML

Qlik AutoML is a predictive tool that leverages automated machine learning capabilities. The platform provides access to its code-free functions allowing users to apply AI and machine learning to recognize patterns in historical data and receive predictions of future outcomes. Users can select the best AI-generated machine learning models for predictive analytics and integrate them directly into the organizations’ ecosystems.

This platform is an excellent solution for any organization looking for software that will generate machine learning models, make predictions, plan decisions, and test scenarios of what will happen in the future.

Key features:

- Associative exploration

- Model development and deployment

- Auto-select the best predictive model

- Feature engineering

- What-if scenarios

- Data visualization

- Automatically generated predictions

Price: $30/month per user.

Future of Supply Chain Analytics

Predictive analytics is a reliable approach to receiving precise business environment forecasts and making data-driven decisions. This technology is gaining momentum thanks to the advanced AI and machine learning algorithms that can analyze previous data and forecast the future.

Data analytics, and predictive analytics, in particular, can be used in any industry. But the supply chain industry benefits the most from data analytics.

If you are going to integrate predictive analytics in supply chain management, you are halfway to success and gaining a competitive advance. But you need a reliable tech partner to select the most-suited predictive analytics platform for your business, create and train the AI model, prepare data, and translate the results into actionable plans. Thus, don’t hesitate to contact the IntelliSoft team. We are ready to relieve all your business needs anytime.