The modern market is unpredictable, like a wide-open ocean. You need a reliable demand forecasting compass to navigate this sea of surprises and manage your supply chain. Forecasting is not just about seeing what’s ahead – it’s about shaping the future with care and insight. It ensures your inventory and your precious cargo arrive right on time. It helps you dodge the dangers of having too much stock and the pitfalls of running out.

In the ever-changing economic seas, where every cent and every moment are crucial, mastering demand forecasting in a supply chain can make or break your success. IntelliSoft has extensive experience in reshaping the logistics industry and can help you with that. It’s not just about cutting costs or expanding; it’s about becoming resilient. With our help, you can learn to predict demand and steer your business toward operational excellence.

Table of Contents

Understanding Demand Forecasting in Supply Chain

So, what is demand forecasting in the supply chain? At the core of effective supply chain handling lies the practice of demand forecasting. It’s a sophisticated process that leverages historical data, deep market analysis, and advanced predictive models to foresee the future need for products or services. This methodology is not just a part of the process – it’s the bedrock upon which the entire supply chain rests.

By accurately predicting demand, your business can finely tune its inventory levels, streamline production planning, and make strategic decisions that align with market needs. The magic of getting demand forecasting right is that it strikes a perfect balance between fulfilling customer expectations and managing costs efficiently, ultimately enhancing a company’s profitability and standing in the market.

Why Accurate Demand Planning Matters?

The precision in demand planning cannot be overstated. It ensures that businesses produce the optimal amount of products and have them available exactly where and when they’re needed. Getting this right means dodging the pitfalls of overproduction, where surplus inventory eats into capital, bloats storage costs, and underproduction can lead to lost sales and dissatisfied customers.

Take, for instance, a company on the cusp of launching a new product. Spot-on demand forecasting primes the supply chain, ensuring there’s enough stock of necessary components, fine-tuning production schedules, and streamlining logistics for on-time delivery. This accuracy helps skirt the dual threats of stockouts and overstocks, paving the way for maximized revenue and minimized risks.

Accurate demand planning lies in its capacity to allocate resources efficiently, optimize production to the fullest, and slash the costs tied to inventory missteps. It allows companies to adapt to market shifts and customer preferences, securing a sustainable path to growth and profitability.

How does Demand Forecasting Work?

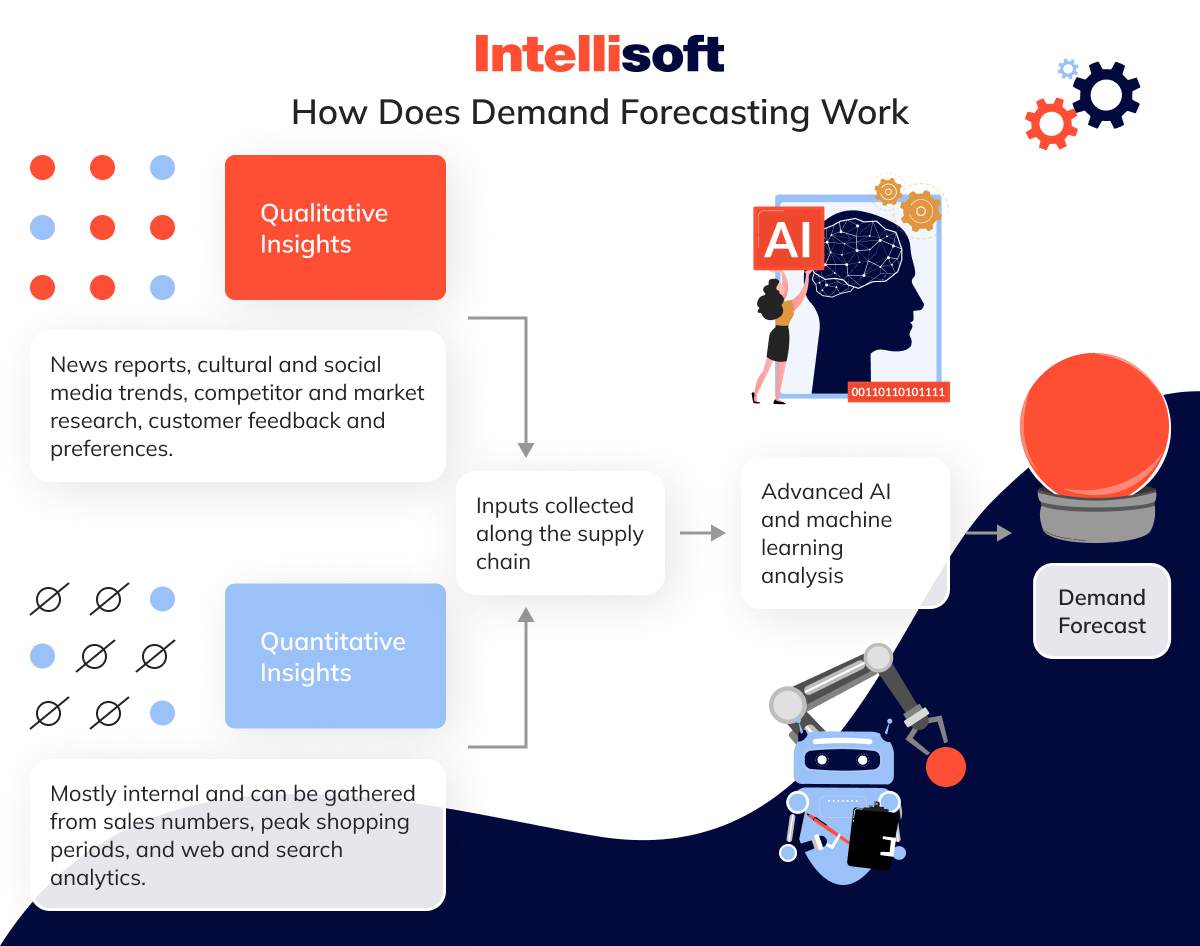

Demand forecasting in a supply chain is a blend of art and science. It combines qualitative and quantitative methods to sketch out future customer demand. This process involves gathering a tapestry of data and analyzing it to unearth patterns and insights.

On one hand, qualitative forecasting dives into the non-numerical side of things—think market trends, consumer behavior, what competitors are up to, and even how the economy is faring or what new laws are on the horizon. This kind of information often comes from places such as news outlets, social media buzz, and deep-dive market research, offering a panoramic view of what might shape demand.

On the flip side, quantitative forecasting zeroes in on hard numbers: past sales, website visits, search trends, and the like. This data, mostly coming from a company’s own backyard (its records and databases), serves as the backbone of forecasting. Here’s where tech steps in, with artificial intelligence (AI) and machine learning crunching these numbers to predict future needs with a sharper lens.

The magic happens when modern tech weaves together insights from both these demand forecasting methods in supply chain, allowing supply chain gurus to navigate the future with more precision and resilience. By deploying predictive analytics, your business is better positioned to meet market demands head-on.

Factors that Affect Supply Chain Demand

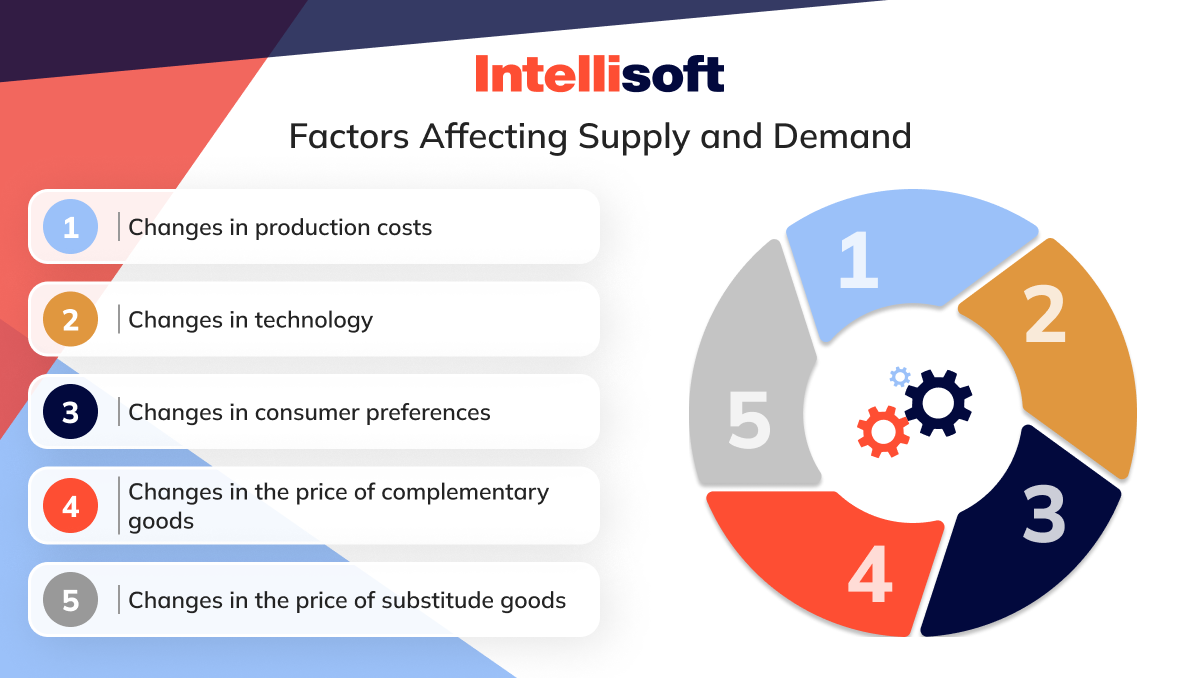

But what stirs the pot in the demand forecast? Several factors can sway supply chain demand, weaving a complex web that businesses must navigate. Economic swings, for one, can send ripples across demand for different products. Seasonal changes play their part, dictating demand for items like winter heaters or summer patio sets. Then, there are shifts in consumer preferences, perhaps towards greener products or healthier food choices, which can reshape demand over time.

Competitor moves, new laws, or global shake-ups like pandemics also toss in their two cents, each influencing demand in their own unpredictable ways. And let’s not forget supply chain hiccups such as a sudden shortage of materials that can throttle the availability of goods. Each of these elements underscores the intricate dance of supply chain demand, spotlighting the need for smart forecasting and agile planning.

Different Techniques of Demand Forecasting

Demand forecasting is a critical navigational tool guiding businesses through the complexities of inventory management, production planning, and market strategy. The foundation of effective demand forecasting lies in the adept use of available information. The precision and utility of forecasting efforts are closely linked to the richness and relevance of the data at hand.

The Essentials of Time-Series Forecasting

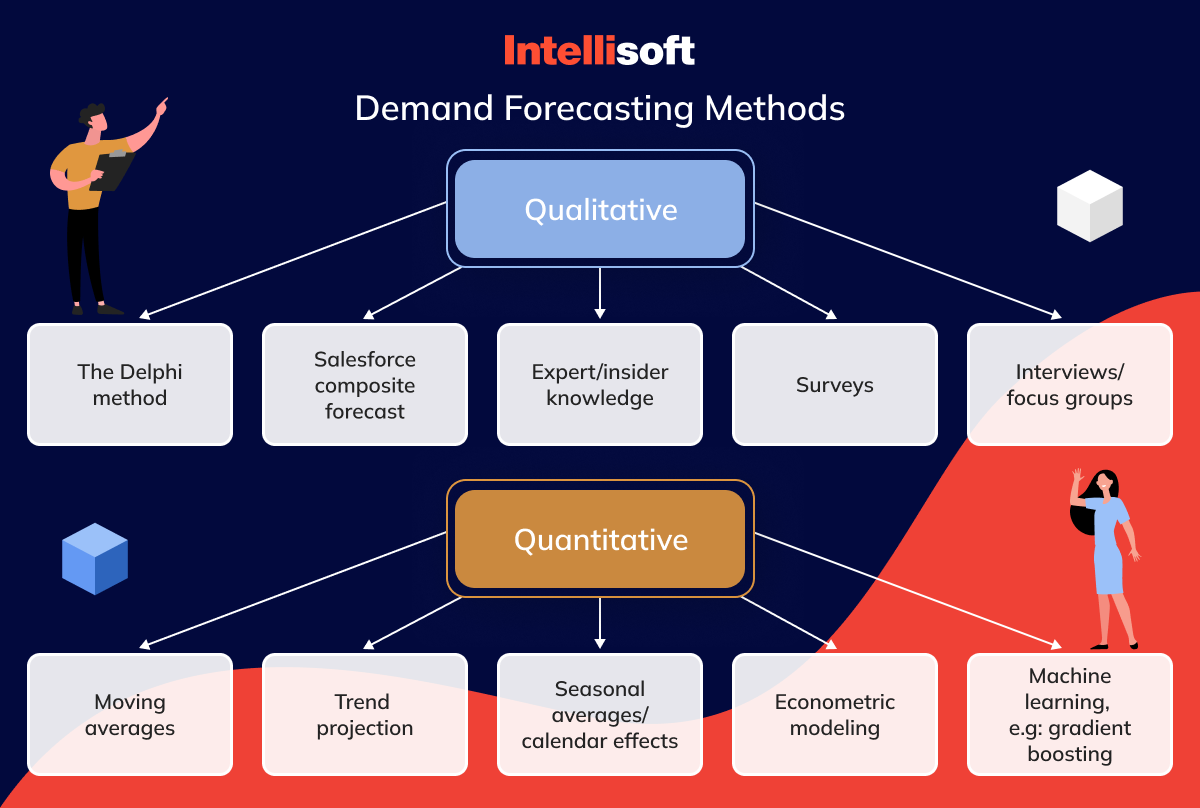

Time-series forecasting, prized for its straightforward approach, is the primary weapon in the arsenal of forecasting tools. It builds on historical sales data, spotting patterns to predict future demands. Its foundational belief is that the past holds keys to the future, making it ideal for consistent markets. Despite its potential oversight of sudden market changes or competitor moves, its simplicity and cost-efficiency stand out as formidable advantages.

Causal Forecasting

Causal forecasting offers a richer data tapestry, examining the cause-and-effect relationships influencing demand. It scrutinizes how economic conditions, promotional efforts, and even weather changes impact consumer behavior, providing a dynamic forecast. While its complexity may seem daunting, the detailed insights it yields are invaluable for strategic planning.

The Art of Qualitative Forecasting

When hard data is scarce, such as during a product launch or market entry, qualitative forecasting shines. This approach gathers expert opinions, thorough market studies, and sometimes even gut feelings, offering foresight in the absence of numerical data. Though its subjective nature is often debated, its ability to tap into industry insights and predict emerging trends is unmatched.

Pushing Boundaries with AI and ML

AI and machine learning, including neural networks, are at the forefront of forecasting. These advanced technologies harness AI’s power to dissect complex data patterns, adapting and learning from new information. Neural networks, in particular, excel in parsing extensive data to unveil hidden trends and provide nuanced predictions. Despite the concerns about their complexity and resource demands, the depth of understanding and accuracy they offer is unparalleled.

Crafting a Comprehensive Forecasting Strategy

Each forecasting method brings its unique strengths and challenges to the table. Time-series forecasting is known for its reliability in stable markets, causal forecasting for its in-depth market insights, qualitative forecasting for its value in data-scarce situations, and AI/ML for its advanced predictive capabilities.

The secret to effective demand forecasting doesn’t lie in a single technique, but in a strategic combination of different methods. Marrying the broad perspectives of qualitative analysis with the detailed accuracy of quantitative methods and enhancing them with AI/ML’s advanced capabilities enables businesses to craft a well-rounded forecasting strategy.

This integrated approach ensures more adaptive, resilient, and efficient market navigation, emphasizing the critical role of adept forecasting in the strategic arsenal of logistics and supply chain management.

Related readings:

- Supply Chain Data Analytics for Efficient Operations

- Warehouse Automation Systems: Revolutionizing Supply Chains for Unprecedented Efficiency

- How Predictive Analytics Solutions Are Benefitting Supply Chain

- How to Develop Logistics Management System: Timeframe, Tech Stack, and Costs

- Machine Learning in Logistics Industry: Benefits and Use Cases

Real-World Success Stories in Demand Forecasting

The power of demand forecasting unfolds in the real-world scenarios of giants like Johnson & Johnson, FedEx, and Nestlé. These stories not only highlight the significance of forecasting in optimizing supply chain efforts but also showcase the practical benefits and innovations driving operational excellence and market adaptability.

Johnson & Johnson: Navigating Healthcare with Precision

In the vital realm of healthcare, where the demand for products can mean life or death, Johnson & Johnson stands out. This healthcare titan leverages cutting-edge analytics and data models to foresee demand across its vast array of products. The adoption of such advanced forecasting methods ensures the timely availability of crucial medical supplies, adhering to strict quality and safety standards, and underpins Johnson & Johnson’s mission to enhance patient care worldwide.

FedEx: Delivering the Future Today

FedEx showcases the pivotal role of demand forecasting in supply chain in the logistics sector. FedEx utilizes macroeconomic insights and historical data to craft forecasts that streamline its delivery network. This strategic foresight allows for effective resource management and timely global deliveries, adjusting adeptly to shifts in e-commerce trends. FedEx’s forecasting prowess not only boosts its operational efficiency but also elevates customer service to new heights.

Nestlé: Feeding the World with Insight

As a behemoth in the food and beverage industry, Nestlé confronts the daunting task of managing an extensive product line. By merging statistical methods with machine learning, Nestlé achieves precise sales predictions, enabling swift production and supply chain adjustments. Integrating real-time data analysis through machine learning gives Nestlé the agility to respond to consumer trends, ensuring product availability while minimizing waste.

The Role of AI in Demand Forecasting

The narratives of Johnson & Johnson, FedEx, and Nestlé underline the transformative impact of AI and ML in demand forecasting. These technologies have become indispensable tools, enhancing data analysis capabilities, uncovering hidden patterns, and forecasting future demand with unmatched accuracy. The application of AI and ML not only streamlines supply chain operations but also supports strategic decision-making, preparing businesses to meet the ever-evolving market demands and consumer preferences proactively.

Your Roadmap to Demand Forecasting Excellence

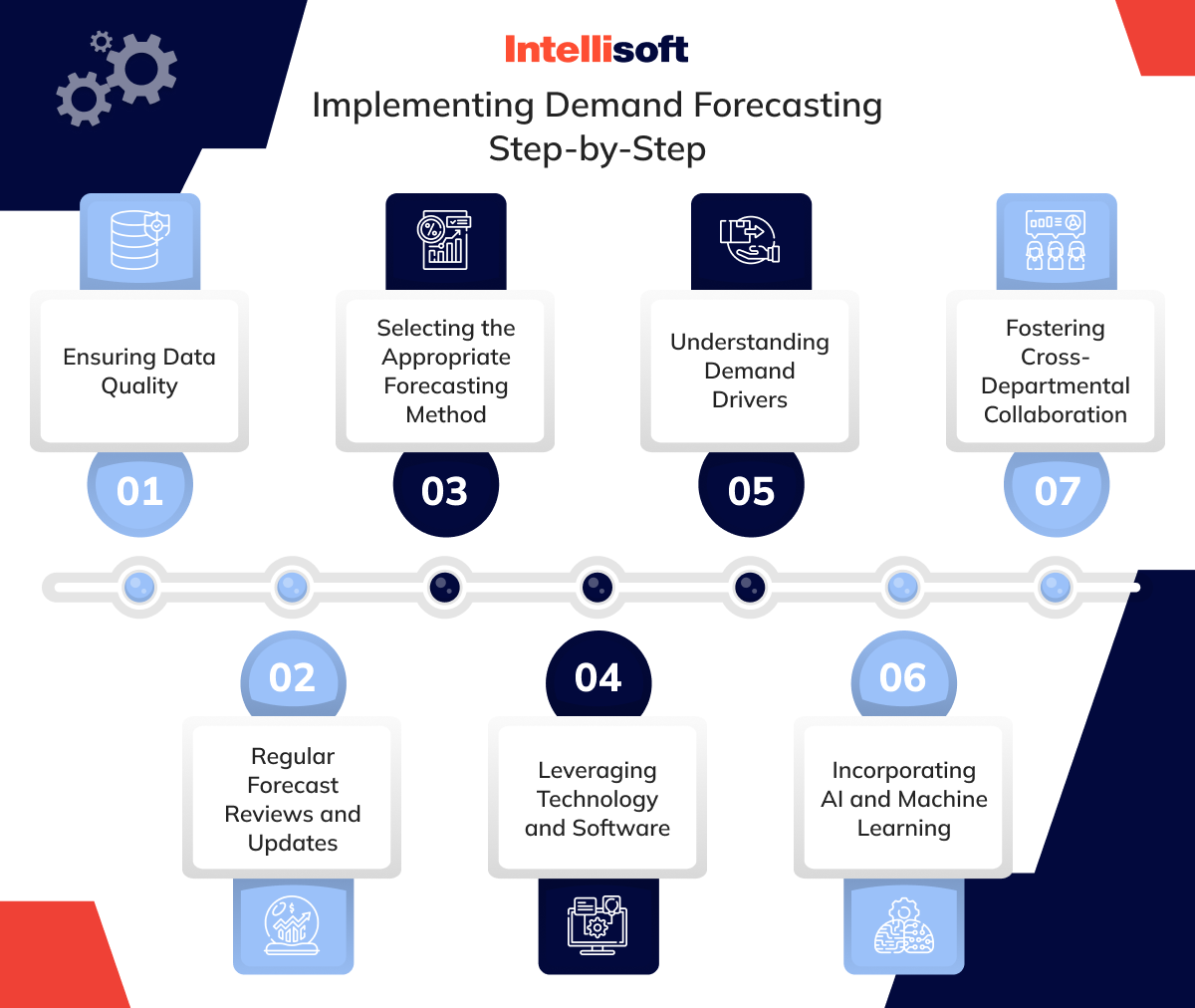

To refine your demand forecasting practices, you may use this step-by-step guide designed to help you navigate the intricate supply chain management landscape. Follow it to harness the full power of forecasting and ensure your business moves with precision and agility.

Start with Stellar Data

The bedrock of all forecasting is top-notch data. It’s crucial to gather detailed, accurate information, keeping it clean and up-to-date to maintain its value. Use advanced analytics to dig deep into this data, uncovering insights that fuel more accurate forecasts.

Pick the Perfect Forecasting Method

Choosing a forecasting method must depend on your business’s unique characteristics. Consider your product diversity, demand patterns, and the impact of external factors like seasonality or economic trends. The right method aligns with your business’s specific needs, making forecasts both precise and practical.

Dive Deep into Demand Drivers

Grasping what steers demand in your sector is vital. Pin down the market trends, consumer behaviors, economic signals, and competitor moves that shape your market. Weaving this understanding into your forecasting sharpens its accuracy and relevance.

Cultivate Collaboration

Forecasting thrives on teamwork. Break down silos and get sales, marketing, operations, and finance departments to share insights. This cross-departmental synergy enriches your forecasting efforts, aligning strategies and honing accuracy.

Keep Forecasts Fresh

The market never stands still, and neither should your forecasts. Regularly revisit and refine your forecasts to mirror the latest market shifts and consumer trends. Integrating feedback from across your organization will keep your forecasts on point.

Embrace the Tech Edge

Modern technology and specialized software can be game-changers for your forecasting process. From automation to real-time analytics, these tools enhance forecasting’s efficiency, accuracy, and scope. Incorporating AI and ML into your forecasting process is transformative. These technologies excel at spotting complex patterns, predicting future trends, and adjusting forecasts in real time. Their inclusion sharpens forecasting accuracy and makes the entire process more agile.

By navigating these steps with care and strategic insight, your business can unlock the extensive benefits of adept demand forecasting. The payoff includes streamlined operations, heightened customer satisfaction, and a robust competitive stance in the market.

Best Examples of Supply Chain Forecasting Software

When you work in the supply chain management field, the software you choose for forecasting can be pivotal in steering your organization through the twists and turns of market demands. Amidst a vast array of options, certain software solutions shine brightly, boasting comprehensive features, cutting-edge analytics, and the power to simplify complex operations. Let’s dive into some of the standout software solutions that are redefining the art of demand planning.

Oracle Demantra: A Beacon of Demand Management

Oracle Demantra stands out for its unparalleled demand management prowess. It arms businesses with advanced analytics and optimization tools, sharpening forecasting accuracy and offering a clear view of the supply chain. With its rich feature set, Oracle Demantra champions data-driven decisions, helping companies fine-tune inventory strategies for optimal performance. Its holistic approach ensures supply chain strategies resonate with wider business goals, making it a top pick for organizations keen on harnessing analytics in demand planning.

SAP Integrated Business Planning (IBP): The Unified Approach

SAP Integrated Business Planning (IBP) is acclaimed for its ability to weave together data strands from across the supply chain, promoting unity among diverse departments. This platform smoothes out the supply chain process from end to end, with powerful analytics and forecasting tools at its core. Businesses can gain vital insights to align demand plans with financial objectives, supporting swift, informed decisions. SAP IBP is a cornerstone for firms dedicated to synchronizing their planning efforts and elevating supply chain efficiency.

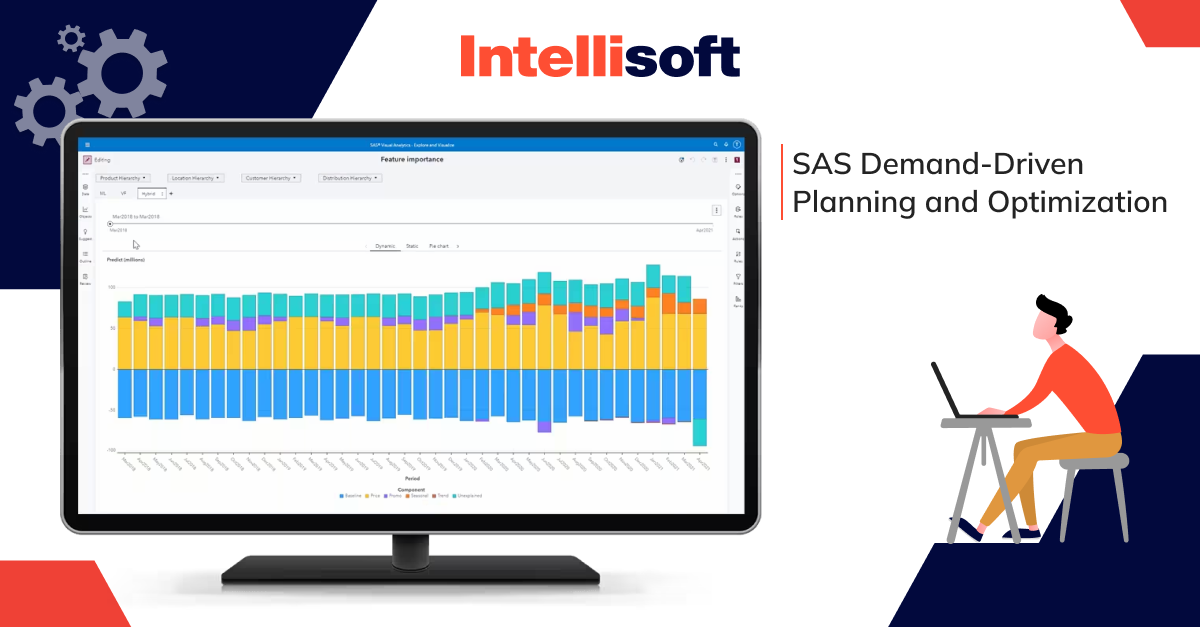

SAS Demand-Driven Planning and Optimization: The Analytical Powerhouse

Famous for deploying top-tier analytics and machine learning, SAS Demand-Driven Planning and Optimization pushes demand forecasting in a supply chain to new heights. This software empowers businesses to craft spot-on demand forecasts and refine their supply chain workflow. By anticipating trends and fine-tuning inventory, it significantly boosts operational efficiency, keeping stockouts and unnecessary costs at bay. SAS’s analytical prowess allows companies to navigate their supply chain strategy with confidence and precision.

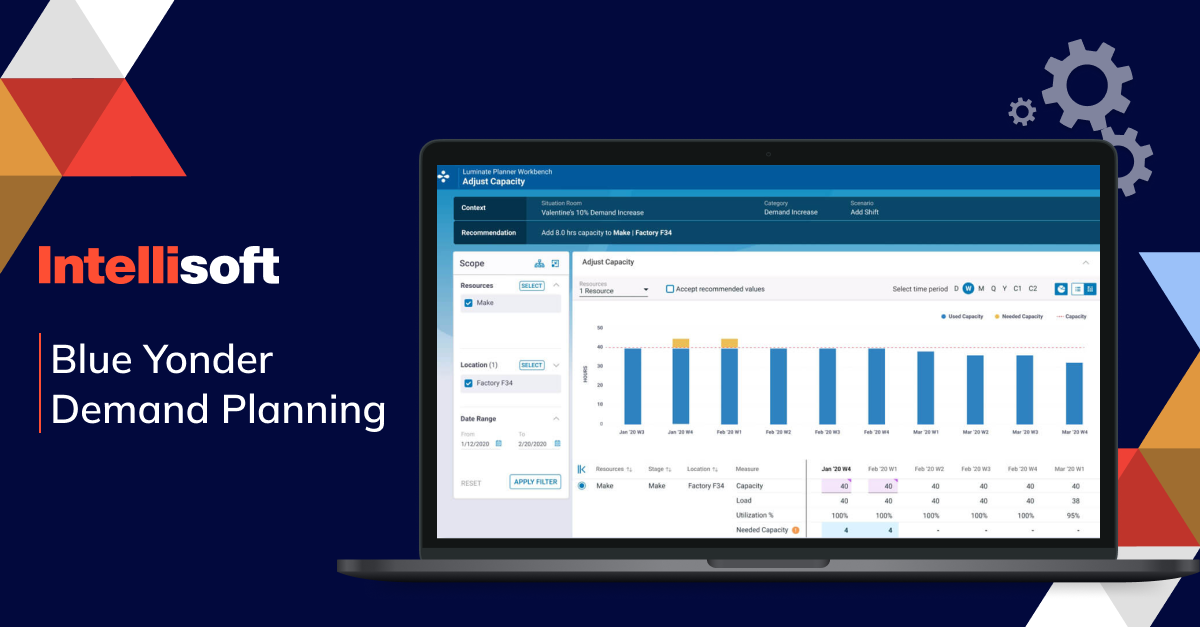

Blue Yonder Demand Planning: Precision and Resilience

Blue Yonder Demand Planning is recognized for its detailed forecasting and inventory management capabilities. It leverages advanced algorithms to aid businesses in achieving the perfect inventory balance, avoiding shortages, and trimming down excess costs. Its user-friendly interface and analytical tools pave the way for accurate demand planning, fostering smarter decision-making. Blue Yonder Demand Planning is a viable solution for organizations aiming to improve forecasting precision and strengthen their operational backbone.

IBM Planning Analytics: Forecasting with Foresight

IBM Planning Analytics is celebrated for its robust forecasting and scenario modeling features. It equips organizations to spot trends and proactively move in dynamic business conditions. This tool is instrumental in developing demand plans that resonate with financial strategies and streamlining supply chain processes. For businesses focused on maintaining agility and aligning their supply chain with financial objectives, IBM Planning Analytics is a formidable ally.

The Advantage of Custom Software

While off-the-shelf software brings notable benefits, custom software development opens up a strategic path for companies aiming to tailor their supply chain forecasting fully. Custom solutions offer unparalleled adaptability, crafted to fit an organization’s unique processes, challenges, and aspirations. This bespoke approach empowers businesses to tackle distinct hurdles and fine-tune every aspect of their forecasting, securing a lasting competitive edge.

Though custom software might require a heftier initial outlay than standard packages, the long-term rewards, such as heightened operational agility and a stronger market position, make it a worthwhile investment. For leaders striving to dominate their sectors, custom software development marks a decisive step towards peak supply chain performance and a sustained competitive lead in a rapidly changing market.

Conclusion

The twists and turns of supply chain management turned out to be a game of insight and foresight. You need to have the right tools at your disposal to make decisions that boost efficiency and adaptability. Our deep dive into the world of demand forecasting has highlighted just how crucial accurate demand planning is and showcased cutting-edge methods for predicting future needs.

This tour has brought us to an essential truth about the incredible impact of making decisions based on solid data. By simply knowing more, you can streamline the supply chain, cut expenses, and meet customer needs more effectively.

IntelliSoft can become your ally in achieving demand forecasting brilliance. We can ensure your business isn’t just reacting but staying ahead. Our commitment to developing custom demand forecasting software means you get more than just a service provider – you get a partner who’s all in on boosting your supply chain’s performance with solutions designed specifically for your business’s challenges and goals.

With our custom software development services, your enterprise can fully leverage AI, machine learning, and in-depth analytics customized for your unique supply chain needs. Step into the future with confidence. Contact us today and take the first step towards the future of new achievements.