After the COVID-19 pandemic, logistics businesses had to find ways to survive and adapt to changed consumer behavior. Cheap, fast, and tracked deliveries became a priority for people, and suppliers, distributors, manufacturers and retailers had to team up and jump on the bandwagon of advanced technology to meet these demands. It may sound like a cliche or buzz, but Artificial Intelligence and Machine Learning technologies once again have entered the game and revolutionized the industry.

ML and AI have become powerful game changers in how packages move around the world and people track their orders, from predictive analytics to autonomous vehicles and even robots and drones that deliver packages. If you have been among the business owners struggling to navigate the post-Covid logistics landscape, AI and ML might be your saviors, but only if you know how to utilize them to your advantage.

Fortunately, at IntelliSoft, we have been guiding companies through the mazes of advanced technologies, AI and machine learning tools for more than 15 years, and we know exactly what steps to take to optimize your business process and transform your company with logistics software development services.

In this article, we’ll team up to discover the real-world machine learning use cases in logistics and supply chain and help you deliver the packages at the speed of light right to your customers’ doorsteps.

Table of Contents

Machine Learning Fundamentals

The terms Machine Learning (ML) and Artificial Intelligence (AI) come hand in hand. ML is the application of AI, providing machines and computers with the ability to learn from experience rather than being programmed. With ML, machines can learn on their own without the need to constantly add new lines of code and control the process.

Machine learning technologies have the capacity to analyze vast datasets, enabling computers to anticipate potential occurrences, detect patterns, categorize information, and enhance their own capabilities. This field encompasses three primary categories of machine learning: supervised, unsupervised, and reinforcement learning.

Supervised learning

This type of learning is called “supervised” for a reason – the machine is supervised while it’s learning. In other words, you’re feeding the algorithm datasets for machine learning. This type of ML uses historical input/output data and shifts between each pair, allowing it to create outputs closely aligned with the desired results.

This type of learning is effective for different business purposes, including inventory optimization, sales forecasting, and fraud detection.

Unsupervised learning

During unsupervised learning, the machine looks for less obvious patterns in machine learning datasets, which is incredibly helpful when you need to improve the decision-making process and use data to identify specific patterns.

This type of ML is often used to create predictive models for clustering (creating models that group objects together based on their properties) and association (identifying the rules that exist between the clusters).

Reinforcement learning

This type of learning is the closest to how humans learn – the algorithms learn by interacting with the environment and getting a positive or negative reward. However, this learning type requires higher computing power, so the majority of organizations cannot afford to use it. Still, it requires less management and human effort than other types of learning, making it easier to work with when dealing with unlabeled machine learning datasets.

Types of ML Models

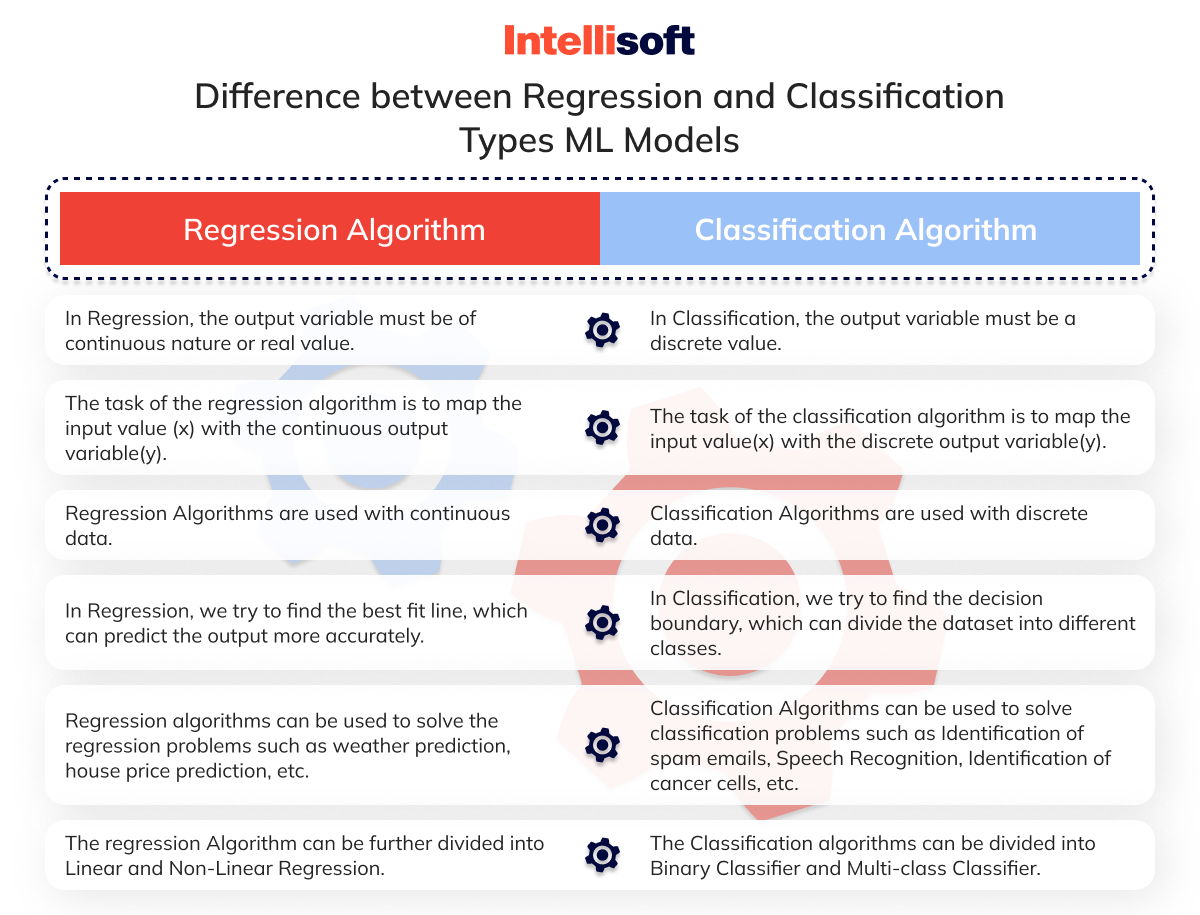

There are two types of ML models: machine learning classification and machine learning regression.

Types of ML Classification Algorithms:

- Logistic Regression

- K-Nearest Neighbors

- Support Vector Machines

- Kernel SVM

- Naïve Bayes

- Decision Tree Classification

- Random Forest Classification

Types of Regression Algorithm:

- Simple Linear Regression

- Multiple Linear Regression

- Polynomial Regression

- Support Vector Regression

- Decision Tree Regression

- Random Forest Regression

Difference between Regression and Classification Types ML Models

Machine Learning in Logistics Market Statistics

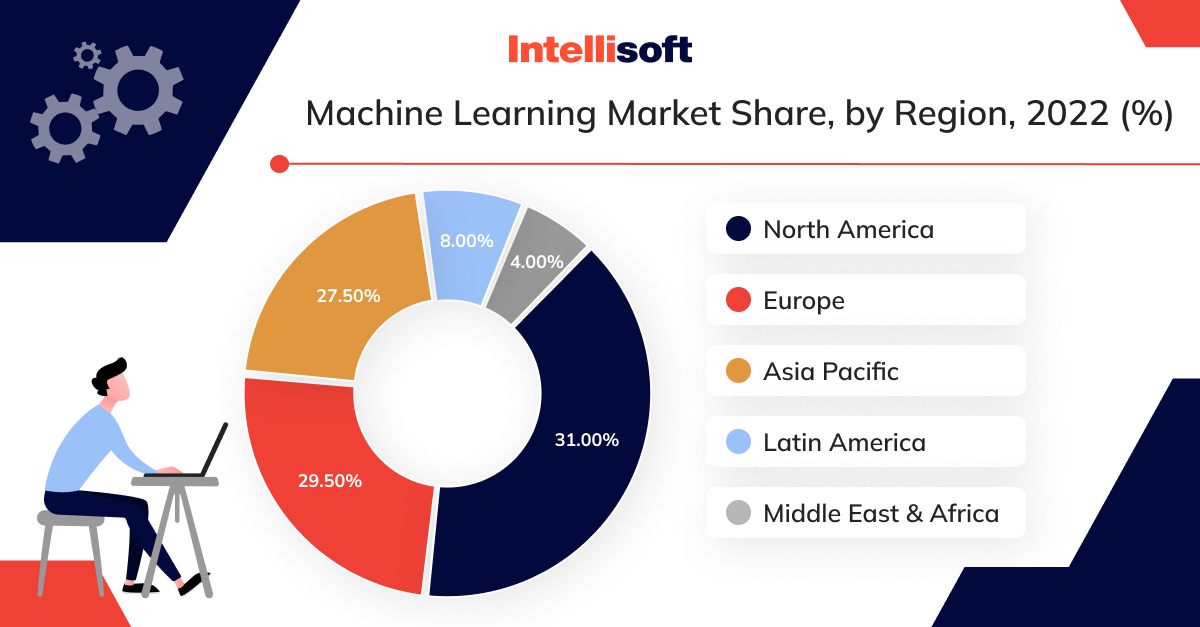

Machine learning is a subpart of the artificial intelligence branch and computer science. Even though it can be considered an emerging technology, it is swiftly growing each day due to its technological advancements. With more companies needing tech solutions for managing complex data and operations, the use of machine learning in logistics and supply chain will continue to expand.

The global machine learning market size was estimated at USD 38.11 billion in 2022, and is projected to surpass around USD 771.38 billion by 2032, expanding at a CAGR of 35.09% during the forecast period from 2023 to 2032.

According to McKinsey, implementing AI has helped companies improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%.

Issues in Machine Learning in Logistics and Supply Chain Management

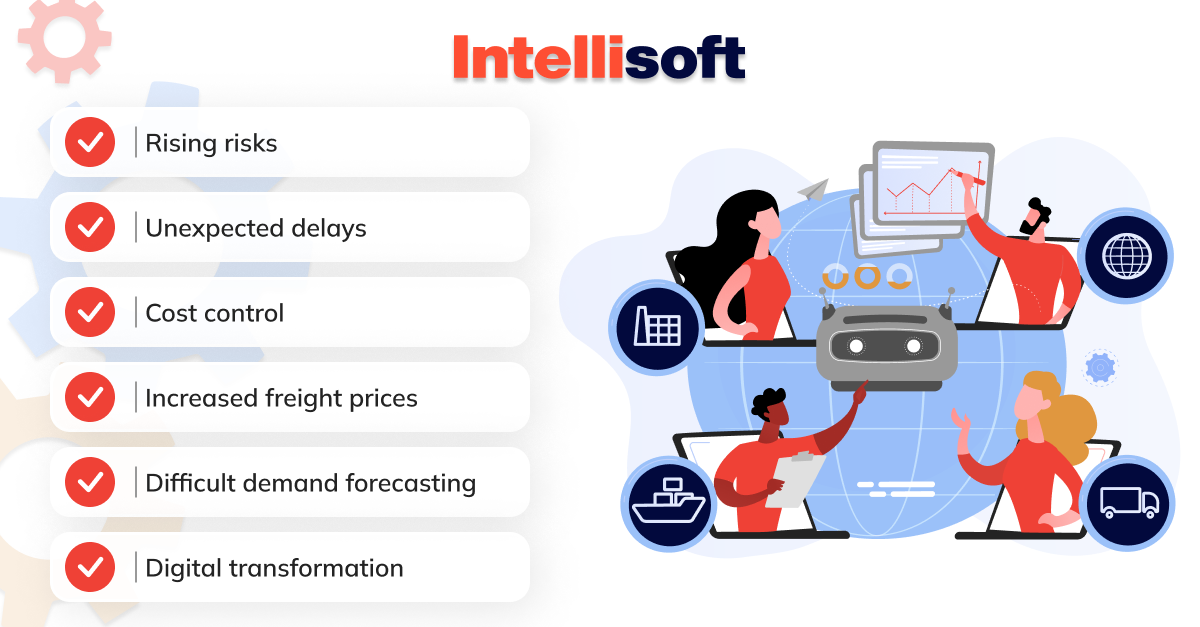

In recent years, especially after the COVID-19 pandemic, the global logistics and supply chain industry has been dealing with unforeseen demand and limited logistics capacity. The machine learning issues still remain, and they include:

- Rising risks

The supply chain industry is filled with risks associated with volatility in the markets. These risks arise from trade wars, changing consumer demands, raw material shortages, strict environmental regulations, climate change, policy changes, etc. The risks can lead to various supply disruptions, increased costs, and challenges in maintaining product quality and compliance with evolving standards. - Unexpected delays

The supply chain is all about large distances and multiple steps, so it’s extremely vulnerable to delays. These delays can be triggered by various factors, including traffic congestion, adverse weather conditions, mechanical breakdowns of vehicles, and unforeseen issues at border crossings. Such delays can ripple through the entire supply chain, affecting production schedules and customer satisfaction. - Cost control

Raw materials, freight, labor, and energy have all gone up in cost worldwide, leading businesses to pay more attention to cost control if they want to ensure there are no disruptions in their operations and processes. - Increased freight prices

Freight prices have also gone up drastically due to the rise in energy prices and the increased demand for container shipping. This challenge affects the logistics industry, pushing business owners to look for ways to save money. To address this issue, businesses are exploring strategies such as optimizing routes, negotiating better contracts, and exploring alternative transportation modes. - Difficult demand forecasting

Nowadays, it is almost impossible to estimate numbers for manufacturing and inventory. The pandemic and the supply chain disruption caused this difficulty. With supply chains still adapting to the post-pandemic world, companies are investing in advanced data analytics, AI-driven predictive modeling, and real-time demand monitoring to enhance their ability to forecast demand accurately. - Digital transformation

The supply chain industry is currently experiencing a digital transformation, which entails the adoption of technologies such as IoT sensors, blockchain, AI and ML, and advanced data analytics to improve visibility, traceability, and operational efficiency. Integrating these digital tools and platforms into existing supply chain processes can be a challenge, often requiring significant investments and changes in organizational culture and practices.

Related Readings:

- The Top 10 Programming Languages Powering AI and Machine Learning

- How to Master an Enterprise Data Warehouse: a Complete Guide

- How To Develop An App For Logistics Business: Detailed Guide

- How Predictive Analytics Solutions Are Benefitting Supply Chain

Benefits of Machine Learning in Logistics Industry

According to a report by McKinsey, AI will create a new “logistics paradigm” by 2030, and for good reason. Let’s take a look at how do machine learning and artificial intelligence technologies help businesses:

Better Data Quality

Enriched data quality is the most important benefit of ML in logistics. Natural Language Processing (NLP) and Machine Learning (ML) help businesses obtain, store, and analyze data faster and more efficiently, drawing connections between the key points and learning simultaneously as the data evolves.

Moreover, the capabilities of ML in logistics allow businesses to use collected data effectively during shipping to avoid risks, come up with better shipment methods and routes, and reduce costs. With all the capabilities of machine learning in logistics and supply chain, companies can utilize machine learning datasets to learn how many people they need to perform certain operations, for how long, and where, even if they need to operate multiple locations.

Improved Predictive Analytics

Not long ago, all logistics operations were performed and assessed manually, mainly by hand. This caused a lot of manual errors and delays that logistics professionals cannot afford today. Fortunately, AI’s predictive analytics help perform all logistics procedures more easily, estimate the upcoming demand, and embrace proactivity. Moreover, AI algorithms can process vast amounts of data in real time, enabling quicker and more informed decision-making, which is critical in a fast-paced logistics environment.

Better Logistics Forecasting

The latest reports predict that AI will increase productivity in logistics by more than 40% by 2035. Today, forecasting the future in logistics is a huge advantage. AI-enhanced logistics forecast in multiple ways. For instance, machine learning technologies can forecast demand more accurately, reducing instances of overstocking or understocking and optimizing inventory levels. AI-powered tracking systems also offer real-time visibility into the status and location of goods, improving transparency and enabling more accurate forecasting.

Strategic Asset Positioning

AI also helps strategically position assets such as warehouses and distribution centers for optimal efficiency. For instance, AI algorithms can determine the most suitable locations for warehouses and distribution centers, considering factors such as demand patterns, transportation networks, and labor availability. Furthermore, improved asset positioning reduces the need for excessive safety stock, leading to lower carrying costs and more cost-effective operations.

Optimized Linehaul and Last-Mile Planning

If logistics companies want to streamline and enhance overall operations, they need to apply AI to line haul operations. Transport networks in shipping are often incredibly complex, making it challenging to figure out the supply chain. AI uses the potential of shipment data, giving companies the possibility to derive data insights and optimize their fleets better.

AI algorithms can evaluate various factors such as traffic conditions, delivery windows, and package size to optimize routes for both linehaul and last-mile delivery. This capability minimizes fuel consumption and delivery times. Moreover, optimized last-mile planning enhances customer satisfaction by ensuring timely and efficient deliveries, which is especially vital in e-commerce and customer-centric industries.

Top Machine Learning Use Cases in Logistics

What is the role of AI in logistics? When it comes to the use cases of AI and machine learning in logistics, the number of possible applications grows day by day as the technology evolves. Machine learning stands as a compass in the intricate web of modern logistics, empowering logistics professionals to chart their course, avoid treacherous waters, and reach their destinations efficiently. Here’s how you can utilize ML in your logistics company to take the most out of this technology:

Inventory management

Inventory management is not only costly but also incredibly challenging when done manually. If you don’t approach inventory planning with the utmost care, it can affect your cash flow and profit margins, and modern logistics companies can’t afford this in today’s industry landscape. AI and ML revolutionize inventory management by predicting demand more accurately, reducing carrying costs, and minimizing the risk of stockouts.

You need large datasets for machine learning for the forecasts to be accurate. Still, it may happen that the number of data sets is not sufficient for the analysis to be effective. That’s when machine learning offers different methods of solving this issue:

- Data augmentation. Since you need the data to be as diverse as possible, this method can help with that without collecting new data. ML will opt for techniques such as SMOTE or SMOTE NC if the data is numerical. For unstructured data (images/text), the techniques will include simple transformations or neural network-generated data, depending on the complexity of the application.

- Incremental learning. This machine learning method does not require large datasets for machine learning. In this case, learning starts with a simple model that predicts the average value. Once new data examples are entered, the ML model learns to predict more accurate results. Thus, with time, the forecasts become more and more accurate.

- Reinforcement learning. This is one of the three main machine learning techniques. It uses reward and punishment as responses to the system’s positive and negative behavior.

Choosing a data storage solution is critical: a data warehouse or data lake. The latter is often used in ML or advanced analytics solutions. Data lake collects data from several sources in real time and stores it in its original format. It’s an ideal solution if you require an in-depth analysis of data that has been gathered over a long period of time.

Choose a data warehouse if you need to deal with operational processes and day-to-day activities. It’s also possible to use both storage options. You can build a data warehouse upon a data lake, and it will use data from DL that is already cleansed and structured.

Warehouse management

Within warehouses, machine learning plays a pivotal role in automating manual tasks, anticipating potential challenges, and minimizing paperwork for warehouse personnel. For instance, computer vision technology facilitates real-time monitoring of conveyor belt operations, predicting potential blockages.

Natural Language Processing (NLP) and Optical Character Recognition (OCR) enable the automatic recognition of incoming packages and seamless updates to their delivery statuses. Cameras are utilized to scan package barcodes and labels, swiftly inputting essential information directly into the system and streamlining warehouse processes.

Machine learning takes a central role in programming ML-powered autonomous vehicles and robots, which have become integral within warehouse operations. Leveraging predefined guides within their systems, autonomous vehicles, and robots facilitate a range of functions, including receiving, packing/unpacking, transportation, and loading/unloading of boxes.

These ML-powered autonomous vehicles not only enhance operational efficiency but also contribute to a safer and more streamlined warehousing process, resulting in increased productivity and reduced operational risks.

Predictive maintenance

AI and ML are transforming the logistics industry in the area of predictive maintenance. What exactly is it? It’s a proactive approach to maintenance that harnesses data analysis and machine learning algorithms to forecast when maintenance will be necessary. This approach empowers logistics companies to detect and address issues before they manifest preemptively, thus proactively ensuring the smooth and uninterrupted operation of their assets and infrastructure.

Predictive maintenance allows companies to combine historical and current data and make more data-driven, intelligent decisions, so they can address the issues before they become too severe and cause downtime.

AI is used in predictive maintenance to analyze vast amounts of data and identify specific patterns that people would not easily identify. For example, AI can identify when maintenance is required by analyzing data from conveyor belts or forklifts, such as temperature, vibration, etc.

Artificial Intelligence in predictive maintenance has multiple benefits, including:

- Reduced downtime. AI helps identify issues before they become too serious. As a result, businesses avoid downtime or systems and machines and save money in the long run.

- Improved equipment lifespan. AI also helps improve equipment lifespan by identifying maintenance needs early. Thus, there’s no need for expensive replacements and maintenance, which helps improve logistics operations’ efficiency.

- Identifying problems before they occur. Thanks to AI’s capabilities, it is possible to identify patterns and reoccurring issues, helping avoid equipment failure and unsafe working conditions that can lead to serious problems. Thus, AI works as a warning mechanism here, helping companies save money and avoid severe problems.

Route optimisation

Logistics heavily relies on route optimization as it helps determine the most efficient routes for carrying parcels from point A to point Z. Route optimization is achieved by considering factors like traffic conditions, distance, and delivery schedules.

Route optimization is possible thanks to AI and its ability to analyze large volumes of data from sources such as traffic sensors, weather forecasts, GPS, etc. By collecting this information and analyzing it, AI can build the fastest routes, help drivers avoid delays, and deliver packages to customers’ doorsteps.

AI in route optimization helps with:

- Reducing fuel costs. Identifying the most efficient routes helps companies reduce fuel costs, which is often the most significant expense in logistics.

- Enhancing driver safety. AI can also be utilized to optimize routes and improve driver safety using data about adverse weather conditions.

- Improving delivery times. Through the optimization of the quickest and most efficient routes, AI has the capacity to assist businesses in enhancing their delivery times, ultimately elevating the overall quality of the customer experience.

Back office operations

In the logistics industry, most back-office operations are performed by people, which not only takes a lot of time, but also prevents employees from focusing on more important activities. These back-office manual tasks include writing emails, processing documents, managing schedules, tracking shipments, and generating reports.

In the past, companies had no choice but to do all of this by hand. Fortunately, there’s no need to waste so much time now as you can rely on AI to automate these tasks and simplify them. For instance, through document automation, it is possible to automate data input, error reconciliation, and processing of invoices, rate sheets, and bills.

AI systems will also help you with scheduling transportation, tracking packages, and even assigning employees to specific stations and tasks. Generating and sending emails can also be automated with AI, helping companies focus on core business activities and increase their overall efficiency.

Dynamic pricing models

The more complex the supply chains become, the harder it is for logistics companies to optimize their operations. One of the possible solutions is to implement a dynamic pricing strategy. It helps reduce manual price adjustments and switch to strategic pricing. This pricing is usually based on factors like supply and demand, competitor prices, and customer behavior.

AI-based dynamic pricing software allows companies to monitor factors influencing pricing and adjust the princess accordingly. This processing helps increase profitability and agility as the market changes and its demands grow. AI and ML can also assist businesses in identifying opportunities for price discrimination.

Demand forecasting

For e-commerce businesses, demand forecasting is a vital aspect as it helps optimize inventory levels, improve supply chain planning, and minimize the risks of waste and stockouts.

Demand forecasting is not easy, though, especially if you have to deal with vast amounts of products and market segments. That’s when AI enters the game. AI-powered demand forecasting systems help e-commerce businesses make more accurate forecasts about sales, optimize inventory levels, and achieve higher efficiency and customer satisfaction.

The use of AI for demand forecasting has the following benefits:

- Improved accuracy of sales predictions. AI provides companies with more accurate predictions of future demand so that businesses can plan their inventory levels and supply chain operations.

- Reduced waste and minimized stockouts. AI helps businesses avoid overstocking and understocking and eliminate the risk of lost revenue or high costs.

- Better supply chain planning. Since AI can accurately predict future demand, businesses can use this capability to optimize their supply chain operations and make sure that they have enough inventory to meet customers’ needs and demands.

Real-Life Examples of Using AI in Logistics

We have already covered the logistics analytics use cases, but let’s look at real-life examples and explore how tech giants such as UPS, DHL, Amazon, and other companies work with AI and benefit from it.

Autonomous vehicles

One of the main use cases of AI in logistics is the use of autonomous vehicles that enhance road safety, save costs, and eliminate human errors. One of the main examples of the use of automated vehicles is the collaboration between UPS and the autonomous vehicle startup TuSimple.

UPS had a goal to reduce delivery times, improve operational efficiency, and cut fuel consumption. TuSimple provides UPS with self-driving trucks that operate on AI systems. These systems use cameras, radar sensors, and lidar to analyze the surroundings and use gathered data about it to make more informed decisions in real time.

FedEx recently started investing in autonomous delivery vehicles as well. These include cars, drones, and robots that will help the company improve last-mile delivery efficiency and save money.

Predictive analytics

More and more companies have started relying on AI’s predictive analytics capability to process data more accurately and forecast more efficiently. One of the main examples is DHL’s use of this feature. The global transportation leader has integrated an AI system that examines posts on social media and other web pages to recognize disruptions in the supply chain.

This feature is possible thanks to natural language processing (NLP) and machine learning (ML) that allow DHL to identify possible access problems, potential shortages, and supplier statuses that may somehow affect the supply chain.

Maersk is another global company that is using AI in its operations. They have an AI-powered virtual assistant, Captain Peter, who provides quick and informative responses to their customers’ questions online and suggests efficient shipping routes. Maersk also uses ML algorithms for forecasting and predictions about the shipping network, allowing the company to improve its operational efficiency and customer satisfaction.

Smart roads

Another use case of AI in logistics is the creation of smart roads that integrate sensors, AI, solar panels, and big data. It helps enhance visibility, communicate with autonomous vehicles, and constantly monitor road conditions. For example, there’s a Smart Mobility Corridor project in Ohio, USA. It is a 35-mile stretch of a highway that has smart sensors built-in and uses AI to monitor traffic conditions, identify congestion points, and detect accidents.

Back office operations

Back-office tasks take a lot of time and attention in the logistics industry. Managing schedules, processing documents, generating reports, tracking shipments, and managing emails can now be automated with AI and robotic process automation (RPA) to simplify these activities and save time for the team to focus on other tasks.

That’s what UPS has done. The company has incorporated an AI-based chatbot called UPS Bot for automating back-office tasks such as shipment tracking, rate quotes, and customer inquiries.

The chatbot understands what users ask it and responds to the questions in natural language. As a result, customer service agents can focus on more complex tasks

Warehouse automation

Robots are now used in multiple warehouses worldwide, helping companies automate the processes. These systems locate, track, and transport goods inside the warehouse as well as sort bigger packages in distribution centers.

For instance, a Dutch tech startup, Fizyr, currently uses robotics for process automation. The company utilizes deep learning algorithms to improve the robotic systems and help them make decisions autonomously. Fizyr’s robots can identify the package type and move the package to its location in 0.2 seconds – something that could never be done manually.

Amazon also utilizes robotics in its day-to-day operations. Robots help employees in sorting, packing, and moving items in the Amazon warehouse, leading to improved inventory and asset management.

Dynamic pricing models

Dynamic pricing strategies are one of the ways to optimize business operations as they reduce manual price adjustments and help create pricing based on factors such as supply and demand, competitor prices, and customer behavior.

AI can assist logistics businesses in monitoring these factors in real life and adjust the prices to improve profitability and stay competitive in the market. Uber Freight, for instance, uses AI-powered algorithms to adjust its pricing based on demand and driver availability.

Convoy also utilized AI and ML for price control. The company aims to stay highly competitive and flexible in the evolving logistics industry.

Challenges in AI Adoption

AI has a whole array of benefits for any business ready to start a new journey with it. From demand forecasting to last mile, AI has proven to be an extremely powerful tool capable of transforming the way companies operate in the competitive landscape.

But, as with any advanced technology, the journey isn’t without bumps and pitfalls; some companies face serious challenges during AI adoption. If you want to come prepared and ready for possible challenges, you’ve come to the right place, as we will explore these problems here.

High costs of implementation and maintenance

Adoption of AI technologies comes with significant investments in infrastructure, hardware, software, and experts who can help you with the process. Apart from initial investments, you would have to spend money on ongoing maintenance, training, updates, and so on to ensure that everything is going smoothly, that your employees know how to deal with the systems, and the technology is providing accurate results. That is the primary reason why smaller companies or those with a limited budget don’t opt for AI technology.

Lack of resources

Yes, AI has revolutionized quite a few industries so far, but it’s still a young technology that has room to grow and change. Thus, it’s no wonder that there’s a lack of resources and technical expertise to implement and manage this technology. Many companies face severe shortages of AI experts as there’s a lack of education on the subject. Moreover, training newly hired employees who are skilled in AI technology increases the costs drastically, as mentioned before.

Privacy and security concerns

One of the biggest concerns around AI usage is connected to its use of customer data and sensitive information. Numerous cybersecurity breaches have made companies hesitant to adopt AI in their operations. With the extensive collection and analysis of sensitive data, including shipment details and supply chain data, there’s a heightened risk of privacy violations.

Protecting this data is paramount, as leaks or unauthorized access could lead to financial losses, reputation damage, and even legal consequences. Striking a balance between leveraging AI’s benefits and ensuring robust privacy and security measures is a pressing challenge for the logistics industry. Security measures require rigorous data encryption, access control, and compliance with data protection regulations to safeguard both sensitive information and the trust of customers and stakeholders.

How to Properly Use Machine Learning in Logistics Industry?

If you are ready to adopt machine learning in your supply chain management, here are the steps you should follow:

Understand your supply chain’s structure

First things first, you should evaluate your current supply chain’s structure:

- Identify the essential elements of your current operations

- Perform an assessment of the supplier network, covering both Tier 1 suppliers and sub-tier suppliers

- Uncover concealed connections and points of interdependence within the network

- Perform a quantitative analysis of the supply chain’s vulnerability

- Recognize potential constraints and factors posing risks in the supply chain

- Make relevant comparisons with industry benchmarks and peers

- Gauge the security status of your supply chain

- Assess your operational maturity in terms of processes, personnel, and technology

Establishing transparent business KPIs and calculating ROI

The next step involves conducting a Discovery Phase to help you identify how AI will help your supply chain operations. You need to calculate ROI, estimate TCO, and the profitability in the long run. Moreover, work on building a detailed plan of goals, needs, and requirements and align your machine learning KPIs with business KPIs.

Ensuring an effective ML engineering process

If you want to ensure an effective ML engineering process, pay attention to these aspects:

- Create a team of skilled professionals in data science, DevOps, Python, Java, QA, BA, etc.

- Create a business problem statement

- Decide on the clear success metrics

- Choose a tech stack

- Focus on data quality and quantity

- Work on development, training, testing, and optimizing AI and ML models

- Deploy and retrain models

- Monitor performance

Conclusion

AI and ML are far from just buzzwords; they are the transformative powers moving the logistics industry, redefining how packages travel the globe and how customers track their orders. Multiple companies all over the world can already see the influence of these advanced systems on their businesses, even though Al is still a young technology with a bright future.

As the industry continues to evolve, businesses that embrace these technologies will be better positioned to thrive in the face of evolving customer demands, supply chain complexities, and global uncertainties. The future of logistics belongs to those who harness the power of AI and ML to optimize their operations, streamline their processes, and deliver exceptional service to their customers.

The time to adopt AI in your operations has come, and IntelliSoft is here to offer its hand to you and guide you through this process. By partnering with us, leveraging cutting-edge AI technology will be smooth, stress-free, and incredibly fruitful, so let us know when you’re ready to start, and we will schedule an initial consultation.